Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wu, Chan-Sheng

Tsai, Ping-Hsiu

Kuo, Chia-Ming

and

Tsai, Che-Wei

2018.

Effect of Atomic Size Difference on the Microstructure and Mechanical Properties of High-Entropy Alloys.

Entropy,

Vol. 20,

Issue. 12,

p.

967.

Su, Yanqing

Xu, Shuozhi

and

Beyerlein, Irene J

2019.

Ab initio-informed phase-field modeling of dislocation core structures in equal-molar CoNiRu multi-principal element alloys.

Modelling and Simulation in Materials Science and Engineering,

Vol. 27,

Issue. 8,

p.

084001.

Jansson, U.

and

Lewin, E.

2019.

Carbon-containing multi-component thin films.

Thin Solid Films,

Vol. 688,

Issue. ,

p.

137411.

Cao, Weitao

Zheng, Mingjie

Ding, Wenyi

Mao, Xiaodong

Wang, Chao

Wang, Wei

and

Xin, Jingping

2019.

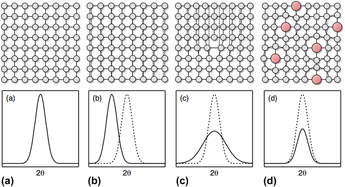

Large relrod extension induced by lattice distortion in high entropy alloy.

Materials Research Express,

Vol. 6,

Issue. 6,

p.

066558.

Sokkalingam, Rathinavelu

Muthupandi, Veerappan

Sivaprasad, Katakam

and

Prashanth, Konda Gokuldoss

2019.

Dissimilar welding of Al0.1CoCrFeNi high-entropy alloy and AISI304 stainless steel.

Journal of Materials Research,

Vol. 34,

Issue. 15,

p.

2683.

Ge, Huijuan

and

Tian, Fuyang

2019.

A Review of Ab Initio Calculation on Lattice Distortion in High-Entropy Alloys.

JOM,

Vol. 71,

Issue. 11,

p.

4225.

Jafary-Zadeh, Mehdi

Khoo, Khoong Hong

Laskowski, Robert

Branicio, Paulo S.

and

Shapeev, Alexander V.

2019.

Applying a machine learning interatomic potential to unravel the effects of local lattice distortion on the elastic properties of multi-principal element alloys.

Journal of Alloys and Compounds,

Vol. 803,

Issue. ,

p.

1054.

Owen, L.R.

and

Jones, N.G.

2020.

Quantifying local lattice distortions in alloys.

Scripta Materialia,

Vol. 187,

Issue. ,

p.

428.

Anand, G.

Eisenbach, Markus

Goodall, Russell

and

Freeman, Colin L.

2020.

Electron spin mediated distortion in metallic systems.

Scripta Materialia,

Vol. 185,

Issue. ,

p.

159.

Nygård, Magnus M.

Sławiński, Wojciech A.

Ek, Gustav

Sørby, Magnus H.

Sahlberg, Martin

Keen, David A.

and

Hauback, Bjørn C.

2020.

Local order in high-entropy alloys and associated deuterides – a total scattering and Reverse Monte Carlo study.

Acta Materialia,

Vol. 199,

Issue. ,

p.

504.

Brenne, F.

Mohammed, A.S.K.

and

Sehitoglu, H.

2020.

High resolution atomic scale characterization of dislocations in high entropy alloys: Critical assessment of template matching and geometric phase analysis.

Ultramicroscopy,

Vol. 219,

Issue. ,

p.

113134.

Lewin, Erik

2020.

Multi-component and high-entropy nitride coatings—A promising field in need of a novel approach.

Journal of Applied Physics,

Vol. 127,

Issue. 16,

Kirnbauer, A.

Kretschmer, A.

Koller, C.M.

Wojcik, T.

Paneta, V.

Hans, M.

Schneider, J.M.

Polcik, P.

and

Mayrhofer, P.H.

2020.

Mechanical properties and thermal stability of reactively sputtered multi-principal-metal Hf-Ta-Ti-V-Zr nitrides.

Surface and Coatings Technology,

Vol. 389,

Issue. ,

p.

125674.

Kaufman, Jonathan

and

Esfarjani, Keivan

2021.

Tunable lattice distortion in MgCoNiCuZnO5 entropy-stabilized oxide.

Journal of Materials Research,

Vol. 36,

Issue. 8,

p.

1615.

Yu, Xiwen

Wang, Bing

Wang, Cheng

Zhuang, Chen

Yao, Yingfang

Li, Zhaosheng

Wu, Congping

Feng, Jianyong

and

Zou, Zhigang

2021.

2D High‐Entropy Hydrotalcites.

Small,

Vol. 17,

Issue. 45,

Pickering, Ed J.

Carruthers, Alexander W.

Barron, Paul J.

Middleburgh, Simon C.

Armstrong, David E. J.

and

Gandy, Amy S.

2021.

High-Entropy Alloys for Advanced Nuclear Applications.

Entropy,

Vol. 23,

Issue. 1,

p.

98.

Farkas, Diana

2021.

Deformation behavior of a model high entropy alloy from atomistic simulations.

Materials Science and Engineering: A,

Vol. 812,

Issue. ,

p.

141124.

Dasari, Sriswaroop

Sharma, Abhishek

Byers, Todd A.

Glass, Gary A.

Srivilliputhur, Srinivasan

Rout, Bibhudutta

and

Banerjee, Rajarshi

2021.

Proton irradiation induced chemical ordering in an Al0.3CoFeNi high entropy alloy.

Applied Physics Letters,

Vol. 119,

Issue. 16,

Adomako, Nana Kwabena

Shin, Giseung

Park, Nokeun

Park, Kyoungtae

and

Kim, Jeoung Han

2021.

Laser dissimilar welding of CoCrFeMnNi-high entropy alloy and duplex stainless steel.

Journal of Materials Science & Technology,

Vol. 85,

Issue. ,

p.

95.

Geslin, Pierre-Antoine

Rida, Ali

and

Rodney, David

2021.

Microelasticity model of random alloys. Part II: displacement and stress correlations.

Journal of the Mechanics and Physics of Solids,

Vol. 153,

Issue. ,

p.

104480.