Article contents

Effects of the alloying element on the stacking fault energies of dilute Ir-based superalloys: A comprehensive first-principles study

Published online by Cambridge University Press: 09 October 2020

Abstract

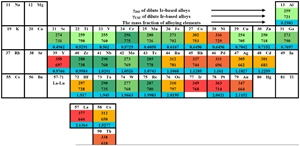

Iridium (Ir) has an extremely high melting point (2443 °C), high chemical stability and is one of the most promising high-temperature materials. However, Ir is more difficult to process compared with other face-centered cubic metals, such as Ni and Al, which limits its applications. To solve this problem, we study the effect of 32 alloying elements (X) on stacking fault energy of dilute Ir-based alloys generated by shear deformation using the first-principles calculations. The investigation reveals that there are many alloying elements studied herein decrease the stacking fault energy of face-centered cubic (fcc) Ir, and the most effective element in reducing stacking fault energy of fcc Ir is Zn. The microscopic mechanism is caused by electron redistribution in the local stacking fault area. These results are expected to provide valuable guidance for the further design and application of Ir-based alloys.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 7

- Cited by