Article contents

Characterization of dynamic and quasistatic compressive mechanical properties of ice-templated alumina–epoxy composites

Published online by Cambridge University Press: 07 March 2019

Abstract

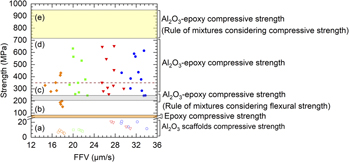

This study investigated the compressive response of ice-templated composites and provides an understanding of their mechanical behavior based on the properties of templated ceramic and epoxy. Results suggested a dependence of properties on the microstructure of the templated porous ceramic, whereas more interestingly composites exhibited catastrophic and progressive types of failure. Compressive strength was found to be markedly greater relative to the strength of templated ceramic and polymer, and irrespective of the failure type, strength was greatly enhanced under dynamic loading relative to quasistatic loading. Compressive strength was also calculated based on the rule of mixtures and mode of failure in ice-templated ceramic. The analysis suggested that the axial mode of failure was not dominant in composites, and failures resulted from the fracture of lamella walls, possibly due to elastic instability. Fragments of the composite specimens were analyzed using scanning electron microscopy to study the fracture characteristics and rationalize the catastrophic and progressive types of failure.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 8

- Cited by