1. Introduction

Thermal convection occurs ubiquitously in nature and has wide applications in industry. A paradigm for the study of thermal convection is the Rayleigh–Bénard (RB) convection, which is a fluid layer heated from the bottom and cooled from the top (Ahlers, Grossmann & Lohse Reference Ahlers, Grossmann and Lohse2009; Lohse & Xia Reference Lohse and Xia2010; Chillà & Schumacher Reference Chillà and Schumacher2012; Xia Reference Xia2013). The control parameters of the canonical RB system include the Rayleigh number (![]() $Ra$, defined later in the paper) that describes the strength of the buoyancy force relative to the thermal and viscous dissipative effects, and the Prandtl number (

$Ra$, defined later in the paper) that describes the strength of the buoyancy force relative to the thermal and viscous dissipative effects, and the Prandtl number (![]() $Pr$) that represents the thermophysical fluid properties. One of the response parameters of the RB system is the Nusselt number (

$Pr$) that represents the thermophysical fluid properties. One of the response parameters of the RB system is the Nusselt number (![]() $Nu$), which characterizes the global heat transfer efficiency. Various approaches have been designed to enhance the heat transfer efficiency of the convection cells, such as adding roughness to the walls (Ciliberto & Laroche Reference Ciliberto and Laroche1999; Wagner & Shishkina Reference Wagner and Shishkina2015; Jiang et al. Reference Jiang, Zhu, Mathai, Verzicco, Lohse and Sun2018; Rusaouën et al. Reference Rusaouën, Liot, Castaing, Salort and Chillà2018; Zhu et al. Reference Zhu, Stevens, Shishkina, Verzicco and Lohse2019), introducing vibration forcing (Wang, Zhou & Sun Reference Wang, Zhou and Sun2020; Yang et al. Reference Yang, Chong, Wang, Verzicco, Shishkina and Lohse2020a), adding a dispersed phase of particles or bubbles (Lakkaraju et al. Reference Lakkaraju, Stevens, Oresta, Verzicco, Lohse and Prosperetti2013; Guzman et al. Reference Guzman, Xie, Chen, Rivas, Sun, Lohse and Ahlers2016; Gvozdić et al. Reference Gvozdić, Alméras, Mathai, Zhu, van Gils, Verzicco, Huisman, Sun and Lohse2018; Wang, Mathai & Sun Reference Wang, Mathai and Sun2019; Yang et al. Reference Yang, Zhang, Wang, Dong and Zhou2022), confinement (Huang et al. Reference Huang, Kaczorowski, Ni and Xia2013; Chong et al. Reference Chong, Yang, Huang, Zhong, Stevens, Verzicco, Lohse and Xia2017; Zhang, Dong & Xia Reference Zhang, Dong and Xia2022), rotation (Stevens et al. Reference Stevens, Zhong, Clercx, Ahlers and Lohse2009; Zhong et al. Reference Zhong, Stevens, Clercx, Verzicco, Lohse and Ahlers2009; Stevens, Clercx & Lohse Reference Stevens, Clercx and Lohse2013; Yang et al. Reference Yang, Verzicco, Lohse and Stevens2020b), and the addition of passive barriers (Liu & Huisman Reference Liu and Huisman2020).

$Nu$), which characterizes the global heat transfer efficiency. Various approaches have been designed to enhance the heat transfer efficiency of the convection cells, such as adding roughness to the walls (Ciliberto & Laroche Reference Ciliberto and Laroche1999; Wagner & Shishkina Reference Wagner and Shishkina2015; Jiang et al. Reference Jiang, Zhu, Mathai, Verzicco, Lohse and Sun2018; Rusaouën et al. Reference Rusaouën, Liot, Castaing, Salort and Chillà2018; Zhu et al. Reference Zhu, Stevens, Shishkina, Verzicco and Lohse2019), introducing vibration forcing (Wang, Zhou & Sun Reference Wang, Zhou and Sun2020; Yang et al. Reference Yang, Chong, Wang, Verzicco, Shishkina and Lohse2020a), adding a dispersed phase of particles or bubbles (Lakkaraju et al. Reference Lakkaraju, Stevens, Oresta, Verzicco, Lohse and Prosperetti2013; Guzman et al. Reference Guzman, Xie, Chen, Rivas, Sun, Lohse and Ahlers2016; Gvozdić et al. Reference Gvozdić, Alméras, Mathai, Zhu, van Gils, Verzicco, Huisman, Sun and Lohse2018; Wang, Mathai & Sun Reference Wang, Mathai and Sun2019; Yang et al. Reference Yang, Zhang, Wang, Dong and Zhou2022), confinement (Huang et al. Reference Huang, Kaczorowski, Ni and Xia2013; Chong et al. Reference Chong, Yang, Huang, Zhong, Stevens, Verzicco, Lohse and Xia2017; Zhang, Dong & Xia Reference Zhang, Dong and Xia2022), rotation (Stevens et al. Reference Stevens, Zhong, Clercx, Ahlers and Lohse2009; Zhong et al. Reference Zhong, Stevens, Clercx, Verzicco, Lohse and Ahlers2009; Stevens, Clercx & Lohse Reference Stevens, Clercx and Lohse2013; Yang et al. Reference Yang, Verzicco, Lohse and Stevens2020b), and the addition of passive barriers (Liu & Huisman Reference Liu and Huisman2020).

Roche et al. (Reference Roche, Castaing, Chabaud and Hébral2002) and Chillà et al. (Reference Chillà, Rastello, Chaumat and Castaing2004) conjectured that the internal flow structure is correlated with global heat transfer. Sun, Xi & Xia (Reference Sun, Xi and Xia2005) compared the ![]() $Nu$ values in a levelled cell and a tilted cell; correspondingly, the large-scale circulation (LSC) plane sweeps azimuthally or is locked in a particular orientation. They showed that

$Nu$ values in a levelled cell and a tilted cell; correspondingly, the large-scale circulation (LSC) plane sweeps azimuthally or is locked in a particular orientation. They showed that ![]() $Nu$ is larger in the levelled cell, indicating that different flow structures can result in different values of

$Nu$ is larger in the levelled cell, indicating that different flow structures can result in different values of ![]() $Nu$. Xi & Xia (Reference Xi and Xia2008) observed both the single-roll and double-roll flow structures in the LSC. They examined the average

$Nu$. Xi & Xia (Reference Xi and Xia2008) observed both the single-roll and double-roll flow structures in the LSC. They examined the average ![]() $Nu$ corresponding to a particular flow structure, and found that the single-roll flow structure is more efficient for heat transfer. Weiss & Ahlers (Reference Weiss and Ahlers2011) further confirmed the occurrence of a double-roll structure in the LSC, and the higher heat transfer efficiency of the single-roll state. van der Poel, Stevens & Lohse (Reference van der Poel, Stevens and Lohse2011) and van der Poel et al. (Reference van der Poel, Stevens, Sugiyama and Lohse2012) showed numerically that the coexistence of different turbulent structures also exists in simple two-dimensional RB cells with various cell aspect ratios. They also studied the effect of various velocity boundary conditions (i.e. no-slip, stress-free and periodic boundary conditions) on the heat transfer and flow topology (van der Poel et al. Reference van der Poel, Ostilla-Mónico, Verzicco and Lohse2014), and they showed that either the roll-like or the zonal flow can appear under different velocity boundary conditions. Adopting Fourier mode decompositions, Xi et al. (Reference Xi, Zhang, Hao and Xia2016) presented direct evidence that the first Fourier mode is more efficient for heat transfer in a cylindrical cell. Xu et al. (Reference Xu, Chen, Wang and Xi2020) analysed the coherent flow structure in two-dimensional square convection cells. Results from both Fourier mode decomposition and proper orthogonal decomposition indicate that the single-roll flow mode and the horizontally stacked double-roll mode are efficient for heat transfer on average; in contrast, the vertically stacked double-roll mode is inefficient for heat transfer on average. A natural question arises on how to manipulate flow mode to control heat transfer efficiency.

$Nu$ corresponding to a particular flow structure, and found that the single-roll flow structure is more efficient for heat transfer. Weiss & Ahlers (Reference Weiss and Ahlers2011) further confirmed the occurrence of a double-roll structure in the LSC, and the higher heat transfer efficiency of the single-roll state. van der Poel, Stevens & Lohse (Reference van der Poel, Stevens and Lohse2011) and van der Poel et al. (Reference van der Poel, Stevens, Sugiyama and Lohse2012) showed numerically that the coexistence of different turbulent structures also exists in simple two-dimensional RB cells with various cell aspect ratios. They also studied the effect of various velocity boundary conditions (i.e. no-slip, stress-free and periodic boundary conditions) on the heat transfer and flow topology (van der Poel et al. Reference van der Poel, Ostilla-Mónico, Verzicco and Lohse2014), and they showed that either the roll-like or the zonal flow can appear under different velocity boundary conditions. Adopting Fourier mode decompositions, Xi et al. (Reference Xi, Zhang, Hao and Xia2016) presented direct evidence that the first Fourier mode is more efficient for heat transfer in a cylindrical cell. Xu et al. (Reference Xu, Chen, Wang and Xi2020) analysed the coherent flow structure in two-dimensional square convection cells. Results from both Fourier mode decomposition and proper orthogonal decomposition indicate that the single-roll flow mode and the horizontally stacked double-roll mode are efficient for heat transfer on average; in contrast, the vertically stacked double-roll mode is inefficient for heat transfer on average. A natural question arises on how to manipulate flow mode to control heat transfer efficiency.

In this work, we impose various types of wall shear to control the internal flow mode, which leads further to modification of heat transfer. Previously, Blass et al. (Reference Blass, Zhu, Verzicco, Lohse and Stevens2020, Reference Blass, Tabak, Verzicco, Stevens and Lohse2021) added a Couette-type shear (i.e. the top and bottom walls move in opposite directions with constant speed ![]() $u_{w}$) to the RB system as an attempt to trigger the transition to the ultimate convection regime (Kraichnan Reference Kraichnan1962). With the increasing wall-shear strength, they observed the variation of flow states from a buoyancy-dominated regime to a shear-dominated regime. In the buoyancy-dominated regime, the flow structure is similar to that in the canonical RB convection; in the transitional regime, the rolls are increasingly elongated with increasing shear; in the shear-dominated regime, there are large-scale meandering rolls. Jin et al. (Reference Jin, Wu, Zhang, Liu and Zhou2022) further added the Couette-type shear to convection cells that have rough walls, and the moving rough plates introduce an external shear to strengthen the LSC. As a result, the interactions between the LSC and secondary flows within cavities are increased, and more thermal plumes are triggered. In this work, our motivation of imposing wall shear is to facilitate various flow modes (i.e. the single-roll, the horizontally stacked double-roll, and the vertically stacked double-roll modes) in the convection cell to further control heat transfer efficiency. Specifically, we will add the

$u_{w}$) to the RB system as an attempt to trigger the transition to the ultimate convection regime (Kraichnan Reference Kraichnan1962). With the increasing wall-shear strength, they observed the variation of flow states from a buoyancy-dominated regime to a shear-dominated regime. In the buoyancy-dominated regime, the flow structure is similar to that in the canonical RB convection; in the transitional regime, the rolls are increasingly elongated with increasing shear; in the shear-dominated regime, there are large-scale meandering rolls. Jin et al. (Reference Jin, Wu, Zhang, Liu and Zhou2022) further added the Couette-type shear to convection cells that have rough walls, and the moving rough plates introduce an external shear to strengthen the LSC. As a result, the interactions between the LSC and secondary flows within cavities are increased, and more thermal plumes are triggered. In this work, our motivation of imposing wall shear is to facilitate various flow modes (i.e. the single-roll, the horizontally stacked double-roll, and the vertically stacked double-roll modes) in the convection cell to further control heat transfer efficiency. Specifically, we will add the ![]() $(m,n)$ type of wall shear to the RB system, and such types of wall shear are expected to facilitate

$(m,n)$ type of wall shear to the RB system, and such types of wall shear are expected to facilitate ![]() $m$ rolls in the horizontal direction and

$m$ rolls in the horizontal direction and ![]() $n$ rolls in the vertical direction. The use of shear-modulated boundary conditions leads essentially to mixed convection, which has received considerable attention due to its importance in many engineering applications, such as cooling of electronic devices, coating, and float glass production (Hunt Reference Hunt1991; Shankar & Deshpande Reference Shankar and Deshpande2000). The rest of this paper is organized as follows. In § 2, we present numerical details for the simulations. In § 3, general flow and heat transfer features are presented, and heat transfer enhancement under various types of wall shear is reported. An interesting finding is thermal turbulence relaminarization under the imposed wall shear, and we then discuss the possible mechanism behind it. In addition, we quantify the efficiency of facilitating heat transport via external shearing. In § 4, the main findings of the present work are summarized.

$n$ rolls in the vertical direction. The use of shear-modulated boundary conditions leads essentially to mixed convection, which has received considerable attention due to its importance in many engineering applications, such as cooling of electronic devices, coating, and float glass production (Hunt Reference Hunt1991; Shankar & Deshpande Reference Shankar and Deshpande2000). The rest of this paper is organized as follows. In § 2, we present numerical details for the simulations. In § 3, general flow and heat transfer features are presented, and heat transfer enhancement under various types of wall shear is reported. An interesting finding is thermal turbulence relaminarization under the imposed wall shear, and we then discuss the possible mechanism behind it. In addition, we quantify the efficiency of facilitating heat transport via external shearing. In § 4, the main findings of the present work are summarized.

2. Numerical method

2.1. Direct numerical simulation of incompressible thermal convection

We consider incompressible thermal convection under the Boussinesq approximation. The temperature is treated as an active scalar, and its influence on the velocity field is realized through the buoyancy term; all the transport coefficients are assumed to be constants. The governing equations can be written as

where ![]() $\boldsymbol {u}$ is the fluid velocity, and

$\boldsymbol {u}$ is the fluid velocity, and ![]() $P$ and

$P$ and ![]() $T$ are the pressure and temperature of the fluid, respectively. Here,

$T$ are the pressure and temperature of the fluid, respectively. Here, ![]() $\beta$,

$\beta$, ![]() $\nu$ and

$\nu$ and ![]() $\alpha$ are the thermal expansion coefficient, kinematic viscosity and thermal diffusivity, respectively. The zero subscripts refer to the reference values;

$\alpha$ are the thermal expansion coefficient, kinematic viscosity and thermal diffusivity, respectively. The zero subscripts refer to the reference values; ![]() $g$ is the gravity acceleration value, and

$g$ is the gravity acceleration value, and ![]() $\hat {\boldsymbol {y}}$ is the unit vector parallel to the gravity. Using the non-dimensional group

$\hat {\boldsymbol {y}}$ is the unit vector parallel to the gravity. Using the non-dimensional group

\begin{equation} \left.\begin{gathered} \boldsymbol{x}^{*}=\boldsymbol{x}/H, \quad t^{*}=t/\sqrt{H/(g\beta \varDelta_{T})}, \quad \boldsymbol{u}^{*}=\boldsymbol{u}/\sqrt{g \beta \varDelta_{T}H}, \\ P^{*}=P/(\rho_{0}g\beta \varDelta_{T}H), \quad T^{*}=(T-T_{0})/\varDelta_{T}, \end{gathered}\right\} \end{equation}

\begin{equation} \left.\begin{gathered} \boldsymbol{x}^{*}=\boldsymbol{x}/H, \quad t^{*}=t/\sqrt{H/(g\beta \varDelta_{T})}, \quad \boldsymbol{u}^{*}=\boldsymbol{u}/\sqrt{g \beta \varDelta_{T}H}, \\ P^{*}=P/(\rho_{0}g\beta \varDelta_{T}H), \quad T^{*}=(T-T_{0})/\varDelta_{T}, \end{gathered}\right\} \end{equation}(2.1)–(2.3) can be rewritten in dimensionless form as

Here, ![]() $H$ is the cell height, and

$H$ is the cell height, and ![]() $\varDelta _{T}$ is the temperature difference between heating and cooling walls. In the following, for convenience, we will drop the superscript star (

$\varDelta _{T}$ is the temperature difference between heating and cooling walls. In the following, for convenience, we will drop the superscript star (![]() $*$) to denote a dimensionless variable. The dimensionless parameters of the Rayleigh number (

$*$) to denote a dimensionless variable. The dimensionless parameters of the Rayleigh number (![]() $Ra$), the Prandtl number (

$Ra$), the Prandtl number (![]() $Pr$) and the cell aspect ratio (

$Pr$) and the cell aspect ratio (![]() $\varGamma _{\parallel}$ in the plane parallel to the LSC plane, and

$\varGamma _{\parallel}$ in the plane parallel to the LSC plane, and ![]() $\varGamma _{\perp }$ in the plane perpendicular to the LSC) are defined as

$\varGamma _{\perp }$ in the plane perpendicular to the LSC) are defined as

where ![]() $L$ is cell length and

$L$ is cell length and ![]() $W$ is cell width.

$W$ is cell width.

We adopt the spectral element method (Patera Reference Patera1984) implemented in the open-source Nek5000 solver (version v19.0) as the numerical tool for the direct numerical simulation. In the Nek5000 solver, the effective grid number equals the product of spectral element number and polynomial order. We set the spectral elements for the velocity with polynomial order ![]() $N$, and the spectral elements for the pressure with polynomial order

$N$, and the spectral elements for the pressure with polynomial order ![]() $N-2$ (to avoid spurious pressure modes). Similar to previous turbulent flow simulations (Kooij et al. Reference Kooij, Botchev, Frederix, Geurts, Horn, Lohse, van der Poel, Shishkina, Stevens and Verzicco2018), we fix the polynomial order as

$N-2$ (to avoid spurious pressure modes). Similar to previous turbulent flow simulations (Kooij et al. Reference Kooij, Botchev, Frederix, Geurts, Horn, Lohse, van der Poel, Shishkina, Stevens and Verzicco2018), we fix the polynomial order as ![]() $N=8$. The viscous term is treated implicitly with the second-order backward difference scheme, while the convection term and other terms are treated with an explicit second-order extrapolation scheme. The discretized system is solved with preconditioned conjugate gradient (PCG) iteration, and Jacobi preconditioning is adopted for the linear velocity system. A pressure correction step follows the solution of the discretized system, which is also solved with PCG iteration; and the linear pressure system is solved by the multilevel overlapping Schwarz method. As for the energy equation (i.e. temperature governed by a convection–diffusion type equation), the transient term is treated implicitly with the second-order backward difference scheme, and the convection term is treated with an explicit second-order extrapolation scheme. For the Navier–Stokes and convection–diffusion equations, the temporal derivative applies a Courant–Friedrichs–Lewy constraint

$N=8$. The viscous term is treated implicitly with the second-order backward difference scheme, while the convection term and other terms are treated with an explicit second-order extrapolation scheme. The discretized system is solved with preconditioned conjugate gradient (PCG) iteration, and Jacobi preconditioning is adopted for the linear velocity system. A pressure correction step follows the solution of the discretized system, which is also solved with PCG iteration; and the linear pressure system is solved by the multilevel overlapping Schwarz method. As for the energy equation (i.e. temperature governed by a convection–diffusion type equation), the transient term is treated implicitly with the second-order backward difference scheme, and the convection term is treated with an explicit second-order extrapolation scheme. For the Navier–Stokes and convection–diffusion equations, the temporal derivative applies a Courant–Friedrichs–Lewy constraint ![]() $\max (|\boldsymbol {u}\,|\Delta_{t}/\Delta_{x})\approx 0.5$. More numerical details of the spectral element method and validation of the Nek5000 solver can be found in Fischer (Reference Fischer1997), Fischer, Kruse & Loth (Reference Fischer, Kruse and Loth2002), Deville, Fischer & Mund (Reference Deville, Fischer and Mund2002) and Kooij et al. (Reference Kooij, Botchev, Frederix, Geurts, Horn, Lohse, van der Poel, Shishkina, Stevens and Verzicco2018). To verify the results obtained from the Nek5000 solver, we also performed a set of simulations at wall-shear Reynolds number (

$\max (|\boldsymbol {u}\,|\Delta_{t}/\Delta_{x})\approx 0.5$. More numerical details of the spectral element method and validation of the Nek5000 solver can be found in Fischer (Reference Fischer1997), Fischer, Kruse & Loth (Reference Fischer, Kruse and Loth2002), Deville, Fischer & Mund (Reference Deville, Fischer and Mund2002) and Kooij et al. (Reference Kooij, Botchev, Frederix, Geurts, Horn, Lohse, van der Poel, Shishkina, Stevens and Verzicco2018). To verify the results obtained from the Nek5000 solver, we also performed a set of simulations at wall-shear Reynolds number (![]() $Re_{w}$, defined later in the paper) 100 using an in-house solver based on the lattice Boltzmann method (Xu, Shi & Zhao Reference Xu, Shi and Zhao2017; Xu, Shi & Xi Reference Xu, Shi and Xi2019; Xu & Li Reference Xu and Li2023). The results from the open-source Nek5000 solver and the in-house lattice Boltzmann solver are shown to be consistent.

$Re_{w}$, defined later in the paper) 100 using an in-house solver based on the lattice Boltzmann method (Xu, Shi & Zhao Reference Xu, Shi and Zhao2017; Xu, Shi & Xi Reference Xu, Shi and Xi2019; Xu & Li Reference Xu and Li2023). The results from the open-source Nek5000 solver and the in-house lattice Boltzmann solver are shown to be consistent.

2.2. Simulation settings

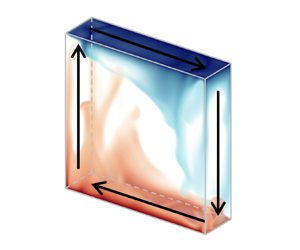

As illustrated in figure 1, the dimensions ![]() $H$,

$H$, ![]() $L$ and

$L$ and ![]() $W$ correspond to

$W$ correspond to ![]() $y$,

$y$, ![]() $x$ and

$x$ and ![]() $z$ in Cartesian coordinates. The top and bottom of the horizontal walls are kept at constant low and high temperatures

$z$ in Cartesian coordinates. The top and bottom of the horizontal walls are kept at constant low and high temperatures ![]() $T_{cold}$ and

$T_{cold}$ and ![]() $T_{hot}$, respectively, while the vertical sidewalls are adiabatic. For the velocity at the walls, we designed the

$T_{hot}$, respectively, while the vertical sidewalls are adiabatic. For the velocity at the walls, we designed the ![]() $(m, n)$ type wall shear to facilitate the flow structure with

$(m, n)$ type wall shear to facilitate the flow structure with ![]() $m$ rolls in the

$m$ rolls in the ![]() $x$-direction and

$x$-direction and ![]() $n$ rolls in the

$n$ rolls in the ![]() $y$-direction. Specifically, we consider three types of wall-shear boundary conditions: the

$y$-direction. Specifically, we consider three types of wall-shear boundary conditions: the ![]() $(1, 1)$ type wall shear that may facilitate the single-roll flow mode (see figures 1a,d); the

$(1, 1)$ type wall shear that may facilitate the single-roll flow mode (see figures 1a,d); the ![]() $(2, 1)$ type wall shear that may facilitate the horizontally stacked double-roll mode (see figures 1b,e); and the

$(2, 1)$ type wall shear that may facilitate the horizontally stacked double-roll mode (see figures 1b,e); and the ![]() $(1, 2)$ type wall shear that may facilitate the vertically stacked double-roll mode (see figures 1c,f). Under the

$(1, 2)$ type wall shear that may facilitate the vertically stacked double-roll mode (see figures 1c,f). Under the ![]() $(1, 1)$ type wall shear, the velocity boundary conditions are: (i) at

$(1, 1)$ type wall shear, the velocity boundary conditions are: (i) at ![]() $0 \leqslant x \leqslant L$ and

$0 \leqslant x \leqslant L$ and ![]() $y=0$, we have

$y=0$, we have ![]() $\boldsymbol {u}=(-u_{w}, 0, 0)$; (ii) at

$\boldsymbol {u}=(-u_{w}, 0, 0)$; (ii) at ![]() $0 \leqslant x \leqslant L$ and

$0 \leqslant x \leqslant L$ and ![]() $y=H$, we have

$y=H$, we have ![]() $\boldsymbol {u}=(u_{w}, 0, 0)$; (iii) at

$\boldsymbol {u}=(u_{w}, 0, 0)$; (iii) at ![]() $x = 0$ and

$x = 0$ and ![]() $0 \leqslant y \leqslant H$, we have

$0 \leqslant y \leqslant H$, we have ![]() $\boldsymbol {u}=(0, u_{w}, 0)$; (iv) at

$\boldsymbol {u}=(0, u_{w}, 0)$; (iv) at ![]() $x=L$ and

$x=L$ and ![]() $0 \leqslant y \leqslant H$, we have

$0 \leqslant y \leqslant H$, we have ![]() $\boldsymbol {u}=(0, -u_{w}, 0)$. Similar mathematical formulations for the velocity boundary conditions under the

$\boldsymbol {u}=(0, -u_{w}, 0)$. Similar mathematical formulations for the velocity boundary conditions under the ![]() $(2, 1)$ type and the

$(2, 1)$ type and the ![]() $(1, 2)$ type wall shear can be written easily (not present here for clarity). When an external wall shear is introduced, an additional control parameter of wall-shear Reynolds number (

$(1, 2)$ type wall shear can be written easily (not present here for clarity). When an external wall shear is introduced, an additional control parameter of wall-shear Reynolds number (![]() $Re_{w}=Hu_{w}/\nu$) is needed. Here,

$Re_{w}=Hu_{w}/\nu$) is needed. Here, ![]() $u_{w}$ is the wall-shear velocity. Simulation results are provided for fixed Rayleigh number

$u_{w}$ is the wall-shear velocity. Simulation results are provided for fixed Rayleigh number ![]() $Ra = 10^{8}$, fixed Prandtl number

$Ra = 10^{8}$, fixed Prandtl number ![]() $Pr = 5.3$ (corresponding to the working fluids of water at

$Pr = 5.3$ (corresponding to the working fluids of water at ![]() $31\,^{\circ }\textrm {C}$ Zhang, Zhou & Sun Reference Zhang, Zhou and Sun2017) and fixed aspect ratio

$31\,^{\circ }\textrm {C}$ Zhang, Zhou & Sun Reference Zhang, Zhou and Sun2017) and fixed aspect ratio ![]() $\varGamma _{\parallel}=1$. In the three-dimensional (3-D) cases, we consider aspect ratios

$\varGamma _{\parallel}=1$. In the three-dimensional (3-D) cases, we consider aspect ratios ![]() $\varGamma _{\perp }=1/8$ and

$\varGamma _{\perp }=1/8$ and ![]() $1/4$ such that the LSC is confined in the

$1/4$ such that the LSC is confined in the ![]() $x$–

$x$–![]() $y$ plane, enabling easy manipulation of the flow mode via wall shear. The wall-shear Reynolds number is in the range

$y$ plane, enabling easy manipulation of the flow mode via wall shear. The wall-shear Reynolds number is in the range ![]() $60 \leqslant Re_{w} \leqslant 6000$ for two-dimensional (2-D) cases, and

$60 \leqslant Re_{w} \leqslant 6000$ for two-dimensional (2-D) cases, and ![]() $Re_{w}=100$ and 3000 for 3-D cases.

$Re_{w}=100$ and 3000 for 3-D cases.

Figure 1. Schematic illustration of the shear convection cells in (a–c) two dimensions and (d–f) three dimensions, for (a,d) the ![]() $(1, 1)$ type wall shear, (b,e) the

$(1, 1)$ type wall shear, (b,e) the ![]() $(2, 1)$ type wall shear, and (c,f) the

$(2, 1)$ type wall shear, and (c,f) the ![]() $(1, 2)$ type wall shear boundary conditions.

$(1, 2)$ type wall shear boundary conditions.

In the simulation, after the initial transient stage, we run at least 5000 ![]() $t_{f}$ for 2-D cases and 800

$t_{f}$ for 2-D cases and 800 ![]() $t_{f}$ for 3-D cases to obtain the statistics. Here,

$t_{f}$ for 3-D cases to obtain the statistics. Here, ![]() $t_{f}$ denotes free-fall time units:

$t_{f}$ denotes free-fall time units: ![]() $t_{f}=\sqrt {H/(g\beta \varDelta _{T})}$. We check whether the grid spacing

$t_{f}=\sqrt {H/(g\beta \varDelta _{T})}$. We check whether the grid spacing ![]() $\varDelta _{g}$ and time interval

$\varDelta _{g}$ and time interval ![]() $\varDelta _{t}$ are properly resolved by comparing them with the Kolmogorov and Batchelor scales. The Kolmogorov length scale can be estimated as

$\varDelta _{t}$ are properly resolved by comparing them with the Kolmogorov and Batchelor scales. The Kolmogorov length scale can be estimated as ![]() $\eta _{K}=(\nu ^{3}/\langle \varepsilon _{u} \rangle )^{1/4}$, the Batchelor length scale can be estimated as

$\eta _{K}=(\nu ^{3}/\langle \varepsilon _{u} \rangle )^{1/4}$, the Batchelor length scale can be estimated as ![]() $\eta _{B}=\eta _{K}\,Pr^{-1/2}$ (Batchelor Reference Batchelor1959; Silano, Sreenivasan & Verzicco Reference Silano, Sreenivasan and Verzicco2010), and the Kolmogorov time scale can be estimated as

$\eta _{B}=\eta _{K}\,Pr^{-1/2}$ (Batchelor Reference Batchelor1959; Silano, Sreenivasan & Verzicco Reference Silano, Sreenivasan and Verzicco2010), and the Kolmogorov time scale can be estimated as ![]() $\tau _{\eta }=\sqrt {\nu /\langle \varepsilon \rangle }$. In the canonical RB convection, we adopted spectral elements of

$\tau _{\eta }=\sqrt {\nu /\langle \varepsilon \rangle }$. In the canonical RB convection, we adopted spectral elements of ![]() $64 \times 64$ for 2-D cases,

$64 \times 64$ for 2-D cases, ![]() $32 \times 32 \times 5$ for 3-D cases with

$32 \times 32 \times 5$ for 3-D cases with ![]() $\varGamma _{\perp }=1/8$, and

$\varGamma _{\perp }=1/8$, and ![]() $32 \times 32 \times 9$ for 3-D cases with

$32 \times 32 \times 9$ for 3-D cases with ![]() $\varGamma _{\perp }=1/4$; the corresponding effective grid numbers are listed in table 1. In the wall-sheared thermal convection, we adopted a finer distributed spectral element of

$\varGamma _{\perp }=1/4$; the corresponding effective grid numbers are listed in table 1. In the wall-sheared thermal convection, we adopted a finer distributed spectral element of ![]() $96 \times 96$ for 2-D cases,

$96 \times 96$ for 2-D cases, ![]() $44 \times 44 \times 7$ for 3-D cases with

$44 \times 44 \times 7$ for 3-D cases with ![]() $\varGamma _{\perp }=1/8$, and

$\varGamma _{\perp }=1/8$, and ![]() $44 \times 44 \times 13$ for 3-D cases with

$44 \times 44 \times 13$ for 3-D cases with ![]() $\varGamma _{\perp }=1/4$. We estimate the global kinetic energy dissipation rate as

$\varGamma _{\perp }=1/4$. We estimate the global kinetic energy dissipation rate as ![]() $\langle \varepsilon _{u} \rangle =Ra\,Pr^{-2}(Nu-1)\nu ^{3}/H^{4}$ in the canonical RB convection (Shraiman & Siggia Reference Shraiman and Siggia1990), and

$\langle \varepsilon _{u} \rangle =Ra\,Pr^{-2}(Nu-1)\nu ^{3}/H^{4}$ in the canonical RB convection (Shraiman & Siggia Reference Shraiman and Siggia1990), and ![]() $\langle \varepsilon _{u} \rangle = \sqrt {Pr/Ra\langle (\partial _{j}u_{i}')\rangle _{V,t}}$ in the wall-sheared convection (Pope Reference Pope2000). Here, the subscripts

$\langle \varepsilon _{u} \rangle = \sqrt {Pr/Ra\langle (\partial _{j}u_{i}')\rangle _{V,t}}$ in the wall-sheared convection (Pope Reference Pope2000). Here, the subscripts ![]() $i$ and

$i$ and ![]() $j$ are dummy indices, and

$j$ are dummy indices, and ![]() $\langle \cdot \rangle _{V,t}$ denotes the spatial and temporal average. As shown in table 1, the maximum grid spacing

$\langle \cdot \rangle _{V,t}$ denotes the spatial and temporal average. As shown in table 1, the maximum grid spacing ![]() $(\varDelta _{g})_{\max }$ is less than (or comparable) to the Kolmogorov and Batchelor length scales for 2-D cases (or 3-D cases); the maximum time interval

$(\varDelta _{g})_{\max }$ is less than (or comparable) to the Kolmogorov and Batchelor length scales for 2-D cases (or 3-D cases); the maximum time interval ![]() $(\varDelta _{t})_{\max }$ is far less than the Kolmogorov time scale for all the cases. Thus adequate spatial and temporal resolution is guaranteed. Each simulation was conducted with 48 message passing interface processes on an in-house cluster that required around 12 000 core hours for 2-D cases and 50 000 core hours for 3-D cases.

$(\varDelta _{t})_{\max }$ is far less than the Kolmogorov time scale for all the cases. Thus adequate spatial and temporal resolution is guaranteed. Each simulation was conducted with 48 message passing interface processes on an in-house cluster that required around 12 000 core hours for 2-D cases and 50 000 core hours for 3-D cases.

Table 1. A posteriori check of spatial and temporal resolutions of the simulations. The columns from left to right indicate the following: imposed wall shear type (‘—’ denotes convection without wall shear), wall-shear Reynolds number ![]() $Re_{w}$, cell aspect ratio

$Re_{w}$, cell aspect ratio ![]() $\varGamma _{\perp }$ in the plane perpendicular to the LSC (‘—’ denotes 2-D cases), effective grid number (i.e. the product of spectral element number and polynomial order), the ratio of maximum grid spacing over the Kolmogorov length scale, the ratio of maximum grid spacing over the Batchelor length scale, and the ratio of maximum time interval over the Kolmogorov time scale. Note that not all the simulations in this work are listed in the table.

$\varGamma _{\perp }$ in the plane perpendicular to the LSC (‘—’ denotes 2-D cases), effective grid number (i.e. the product of spectral element number and polynomial order), the ratio of maximum grid spacing over the Kolmogorov length scale, the ratio of maximum grid spacing over the Batchelor length scale, and the ratio of maximum time interval over the Kolmogorov time scale. Note that not all the simulations in this work are listed in the table.

3. Results and discussion

3.1. Global flow and heat transfer features

Typical snapshots of temperature field and flow field under the three types of wall shear are shown in figure 2, and the corresponding video can be viewed in supplementary movie 1 available at https://doi.org/10.1017/jfm.2023.173. Here, ![]() $Ra$ is fixed as

$Ra$ is fixed as ![]() $Ra=10^{8}$ and

$Ra=10^{8}$ and ![]() $Pr$ is fixed as

$Pr$ is fixed as ![]() $Pr=5.3$. At small wall-shear strength

$Pr=5.3$. At small wall-shear strength ![]() $Re_{w} = 100$, the convection is still buoyancy-dominated, and plumes detach from thermal boundary layers and further self-organize into the LSC; meanwhile, the flow structure in the convection cell is influenced by the imposed wall shear. For the convenience of comparison, we also provide the flow and heat transfer patterns in the canonical RB convection without wall shear (see Appendix A). The single-roll flow structure appears under the

$Re_{w} = 100$, the convection is still buoyancy-dominated, and plumes detach from thermal boundary layers and further self-organize into the LSC; meanwhile, the flow structure in the convection cell is influenced by the imposed wall shear. For the convenience of comparison, we also provide the flow and heat transfer patterns in the canonical RB convection without wall shear (see Appendix A). The single-roll flow structure appears under the ![]() $(1, 1)$ type wall shear (see figures 2a,g), whilst the corner rolls are suppressed compared to that without wall shear; the horizontally stacked double-roll flow structure appears under the

$(1, 1)$ type wall shear (see figures 2a,g), whilst the corner rolls are suppressed compared to that without wall shear; the horizontally stacked double-roll flow structure appears under the ![]() $(2, 1)$ type wall shear (see figures 2b,h); and the vertically stacked double-roll flow structure appears under the

$(2, 1)$ type wall shear (see figures 2b,h); and the vertically stacked double-roll flow structure appears under the ![]() $(1, 2)$ type wall shear (see figures 2c,i). At large wall-shear strength

$(1, 2)$ type wall shear (see figures 2c,i). At large wall-shear strength ![]() $Re_{w} = 4000$ in two dimensions and

$Re_{w} = 4000$ in two dimensions and ![]() $Re_{w}=3000$ in three dimensions, the convection is shear-dominated, and the flow structures inside the convection cell are completely influenced by the external wall shear. For example, under the

$Re_{w}=3000$ in three dimensions, the convection is shear-dominated, and the flow structures inside the convection cell are completely influenced by the external wall shear. For example, under the ![]() $(1, 1)$ type wall shear (see figures 2d,j), the hot (or cold) fluids near the bottom (or top) wall are swept away by the LSC in the clockwise direction, and rise (or fall) along the left (or right) vertical wall, while the fluids in the bulk region are well-mixed. Similar observations can be found for the flow structure under the

$(1, 1)$ type wall shear (see figures 2d,j), the hot (or cold) fluids near the bottom (or top) wall are swept away by the LSC in the clockwise direction, and rise (or fall) along the left (or right) vertical wall, while the fluids in the bulk region are well-mixed. Similar observations can be found for the flow structure under the ![]() $(2, 1)$ type wall shear (see figures 2e,k), while the cold fluids also fall along the vertical mid-plane of the cell. As for the flow structure under the

$(2, 1)$ type wall shear (see figures 2e,k), while the cold fluids also fall along the vertical mid-plane of the cell. As for the flow structure under the ![]() $(1, 2)$ type wall shear, in the 2-D case (see figure 2f), the top and bottom subregions are completed separated without heat transfer between them, acting as a ‘thermal barrier’ exists at the half-height of the cell; however, in the 3-D case (see figure 2l), we did not observe a complete separation of hot and cold fluids. We infer that the differences in flow structure between 2-D and 3-D configurations are due to the flow state: in the steady laminar flow (as in the 2-D case), the rising hot fluids and falling cold fluids can remain stable boundaries; while in the turbulent flow (as in the 3-D case), the hot and cold fluids are more mixed. We also checked the flow field within the

$(1, 2)$ type wall shear, in the 2-D case (see figure 2f), the top and bottom subregions are completed separated without heat transfer between them, acting as a ‘thermal barrier’ exists at the half-height of the cell; however, in the 3-D case (see figure 2l), we did not observe a complete separation of hot and cold fluids. We infer that the differences in flow structure between 2-D and 3-D configurations are due to the flow state: in the steady laminar flow (as in the 2-D case), the rising hot fluids and falling cold fluids can remain stable boundaries; while in the turbulent flow (as in the 3-D case), the hot and cold fluids are more mixed. We also checked the flow field within the ![]() $\varGamma _{\perp }=1/8$ cell, where the flow is in a laminar state, and we indeed found a separation of hot and cold fluids.

$\varGamma _{\perp }=1/8$ cell, where the flow is in a laminar state, and we indeed found a separation of hot and cold fluids.

Figure 2. Typical instantaneous temperature field (contours in two dimensions and volume rendering in three dimensions) and flow field (streamlines in two dimensions) at (a–c) ![]() $Re_{w} = 100$, (d–f)

$Re_{w} = 100$, (d–f) ![]() $Re_{w} = 4000$, (g–i)

$Re_{w} = 4000$, (g–i) ![]() $Re_{w} = 100$ and

$Re_{w} = 100$ and ![]() $\varGamma _{\perp }=1/4$, ( j–l)

$\varGamma _{\perp }=1/4$, ( j–l) ![]() $Re_{w} = 3000$ and

$Re_{w} = 3000$ and ![]() $\varGamma _{\perp }=1/4$, under (a,d,g,j) the

$\varGamma _{\perp }=1/4$, under (a,d,g,j) the ![]() $(1, 1)$ type wall shear, (b,e,h,k) the

$(1, 1)$ type wall shear, (b,e,h,k) the ![]() $(2, 1)$ type wall shear, and (c,f,i,l) the

$(2, 1)$ type wall shear, and (c,f,i,l) the ![]() $(1, 2)$ type wall shear.

$(1, 2)$ type wall shear.

With simulations of three different types of wall shear in the range ![]() $60 \leqslant Re_{w} \leqslant 6000$, we can obtain the phase diagram of whether the flow is in the turbulent state or laminar state, as shown in figure 3(a) for 2-D cases. Here, we placed numerical probers in the cell and analysed the time recordings of local velocity and temperature series to determine the flow states (Heslot, Castaing & Libchaber Reference Heslot, Castaing and Libchaber1987; Silano et al. Reference Silano, Sreenivasan and Verzicco2010). We determined that the flow is in the laminar state if the time recordings do not vary with time (i.e. steady laminar state) or the power spectral density (PSD) of the time recordings exhibits characteristic peaks (i.e. unsteady laminar state); otherwise, if the PSD of the time recordings exhibits continuous spectra, then the flow is in the turbulent state. In Appendix B, we give examples of temperature series and the corresponding PSD at the location

$60 \leqslant Re_{w} \leqslant 6000$, we can obtain the phase diagram of whether the flow is in the turbulent state or laminar state, as shown in figure 3(a) for 2-D cases. Here, we placed numerical probers in the cell and analysed the time recordings of local velocity and temperature series to determine the flow states (Heslot, Castaing & Libchaber Reference Heslot, Castaing and Libchaber1987; Silano et al. Reference Silano, Sreenivasan and Verzicco2010). We determined that the flow is in the laminar state if the time recordings do not vary with time (i.e. steady laminar state) or the power spectral density (PSD) of the time recordings exhibits characteristic peaks (i.e. unsteady laminar state); otherwise, if the PSD of the time recordings exhibits continuous spectra, then the flow is in the turbulent state. In Appendix B, we give examples of temperature series and the corresponding PSD at the location ![]() $(0.25, 0.5)$ in the 2-D convection cell under

$(0.25, 0.5)$ in the 2-D convection cell under ![]() $(1, 1)$ type wall shear. The phase diagram of the flow states can be understood in terms of competition between buoyancy and shear effects, which can be quantified by the Richardson number as

$(1, 1)$ type wall shear. The phase diagram of the flow states can be understood in terms of competition between buoyancy and shear effects, which can be quantified by the Richardson number as ![]() $Ri=Ra/(Re_{w}^{2}\,Pr)$. In figure 3(b), we redraw the phase diagram of the flow states at different

$Ri=Ra/(Re_{w}^{2}\,Pr)$. In figure 3(b), we redraw the phase diagram of the flow states at different ![]() $Ri$. For lower

$Ri$. For lower ![]() $Re_{w}$ (i.e. higher

$Re_{w}$ (i.e. higher ![]() $Ri$ at fixed

$Ri$ at fixed ![]() $Ra$ and

$Ra$ and ![]() $Pr$), the flow is buoyancy-dominated and possesses the key features of turbulent convection; for higher

$Pr$), the flow is buoyancy-dominated and possesses the key features of turbulent convection; for higher ![]() $Re_{w}$ (i.e. lower

$Re_{w}$ (i.e. lower ![]() $Ri$), the flow is shear-dominated and enters a laminar state. Turbulent laminarization is counterintuitive and is found recently in pipe flow by amplifying wall shear (Kühnen et al. Reference Kühnen, Song, Scarselli, Budanur, Riedl, Willis, Avila and Hof2018; Scarselli, Kühnen & Hof Reference Scarselli, Kühnen and Hof2019). It should also be noted that when

$Ri$), the flow is shear-dominated and enters a laminar state. Turbulent laminarization is counterintuitive and is found recently in pipe flow by amplifying wall shear (Kühnen et al. Reference Kühnen, Song, Scarselli, Budanur, Riedl, Willis, Avila and Hof2018; Scarselli, Kühnen & Hof Reference Scarselli, Kühnen and Hof2019). It should also be noted that when ![]() $Re_{w}$ increases further, the wall shear would introduce flow instability and the flow would transit to a turbulent state again. However, our numerical tests show that the flow can remain laminar for a wide range of

$Re_{w}$ increases further, the wall shear would introduce flow instability and the flow would transit to a turbulent state again. However, our numerical tests show that the flow can remain laminar for a wide range of ![]() $Re_{w}$ in 2-D cases; a further transition to shear turbulence may occur at a much higher

$Re_{w}$ in 2-D cases; a further transition to shear turbulence may occur at a much higher ![]() $Re_{w}$. We also found that the shear instability is prominent in 3-D cases, particularly when

$Re_{w}$. We also found that the shear instability is prominent in 3-D cases, particularly when ![]() $\varGamma _{\perp }$ is larger, thus the flow remains laminar in a smaller range of wall-shear Reynolds number. For example, at

$\varGamma _{\perp }$ is larger, thus the flow remains laminar in a smaller range of wall-shear Reynolds number. For example, at ![]() $Re_{w}=3000$, the flow is laminar in convection cells with

$Re_{w}=3000$, the flow is laminar in convection cells with ![]() $\varGamma _{\perp }=1/8$ under all three types of wall shear, while the flow is laminar only under the

$\varGamma _{\perp }=1/8$ under all three types of wall shear, while the flow is laminar only under the ![]() $(1, 1)$ type wall shear in the

$(1, 1)$ type wall shear in the ![]() $\varGamma _{\perp }=1/4$ cell.

$\varGamma _{\perp }=1/4$ cell.

Figure 3. Phase diagram of the flow states (a) at different ![]() $Re_{w}$, and (b) at different

$Re_{w}$, and (b) at different ![]() $Ri$, in 2-D cases.

$Ri$, in 2-D cases.

We then examine the global response parameters of Nusselt number (![]() $Nu$) and Reynolds number (

$Nu$) and Reynolds number (![]() $Re$) on the control parameter

$Re$) on the control parameter ![]() $Re_{w}$. Here, the heat transfer efficiency is calculated as

$Re_{w}$. Here, the heat transfer efficiency is calculated as ![]() $Nu=\sqrt {Ra\,Pr}\,\langle vT \rangle _{V,t}+1$, and the global flow strength is calculated as

$Nu=\sqrt {Ra\,Pr}\,\langle vT \rangle _{V,t}+1$, and the global flow strength is calculated as ![]() $Re=\sqrt {\langle \|\boldsymbol {u}\|^{2} \rangle _{V,t}}\,H/\nu$. The measured

$Re=\sqrt {\langle \|\boldsymbol {u}\|^{2} \rangle _{V,t}}\,H/\nu$. The measured ![]() $Nu$ and

$Nu$ and ![]() $Re$ as functions of

$Re$ as functions of ![]() $Re_{w}$ for various types of wall shear in 2-D cells are shown in figures 4(a) and 4(b), respectively. Generally, with the increase of

$Re_{w}$ for various types of wall shear in 2-D cells are shown in figures 4(a) and 4(b), respectively. Generally, with the increase of ![]() $Re_{w}$, we can observe enhanced heat transfer efficiency and global flow strength for all three types of wall shear. However, at

$Re_{w}$, we can observe enhanced heat transfer efficiency and global flow strength for all three types of wall shear. However, at ![]() $Re_{w} \leqslant 200$ for the

$Re_{w} \leqslant 200$ for the ![]() $(1, 2)$ type wall shear, the flow structure gradually changes from an LSC that spans the whole cell to the vertically stacked double-roll mode, leading to a decreased

$(1, 2)$ type wall shear, the flow structure gradually changes from an LSC that spans the whole cell to the vertically stacked double-roll mode, leading to a decreased ![]() $Nu$ value (Xu et al. Reference Xu, Chen, Wang and Xi2020). To clearly visualize the relative changes of

$Nu$ value (Xu et al. Reference Xu, Chen, Wang and Xi2020). To clearly visualize the relative changes of ![]() $Nu$ and

$Nu$ and ![]() $Re$ after imposing the wall shear, we further plot

$Re$ after imposing the wall shear, we further plot ![]() $(Nu-Nu_{0})/Nu_{0}$ and

$(Nu-Nu_{0})/Nu_{0}$ and ![]() $(Re-Re_{0})/Re_{0}$ as functions of

$(Re-Re_{0})/Re_{0}$ as functions of ![]() $Re_{w}$ in figures 4(c) and 4(d), respectively. Here,

$Re_{w}$ in figures 4(c) and 4(d), respectively. Here, ![]() $Nu_{0}$ and

$Nu_{0}$ and ![]() $Re_{0}$ are the Nusselt and Reynolds numbers in the absence of wall shear, respectively. Among the three types of wall shear, at the same

$Re_{0}$ are the Nusselt and Reynolds numbers in the absence of wall shear, respectively. Among the three types of wall shear, at the same ![]() $Re_{w}$, the

$Re_{w}$, the ![]() $(2, 1)$ type wall shear results in the largest magnitude of heat transfer efficiency up to 568 %; and the

$(2, 1)$ type wall shear results in the largest magnitude of heat transfer efficiency up to 568 %; and the ![]() $(1, 2)$ type wall shear results in the smallest one, approximately 179 %. The trend is consistent with our expectation that facilitating the horizontally stacked double-roll flow modes is efficient for heat transfer, yet facilitating the vertically stacked double-roll is inefficient for heat transfer (Xu et al. Reference Xu, Chen, Wang and Xi2020). On the other hand, as

$(1, 2)$ type wall shear results in the smallest one, approximately 179 %. The trend is consistent with our expectation that facilitating the horizontally stacked double-roll flow modes is efficient for heat transfer, yet facilitating the vertically stacked double-roll is inefficient for heat transfer (Xu et al. Reference Xu, Chen, Wang and Xi2020). On the other hand, as ![]() $Re_{w}$ increases, all three types of wall shear exhibit a similar trend of increasing global flow strength. The results indicate that in even with the same magnitude of flow strength, the heat transfer efficiency of the convection cell still varies significantly under different types of wall shear. In addition, we provide tabulated value of Nusselt and Reynolds numbers for 3-D cases in table 2. We can conclude that heat transfer enhancement can also be found in 3-D configurations.

$Re_{w}$ increases, all three types of wall shear exhibit a similar trend of increasing global flow strength. The results indicate that in even with the same magnitude of flow strength, the heat transfer efficiency of the convection cell still varies significantly under different types of wall shear. In addition, we provide tabulated value of Nusselt and Reynolds numbers for 3-D cases in table 2. We can conclude that heat transfer enhancement can also be found in 3-D configurations.

Figure 4. (a) Nusselt number, (b) Reynolds number, (c) values of ![]() $Nu/Nu_{0}-1$, and (

$Nu/Nu_{0}-1$, and (![]() $\textit {d}$) values of

$\textit {d}$) values of ![]() $Re/Re_{0}-1$, as functions of

$Re/Re_{0}-1$, as functions of ![]() $Re_{w}$ for various types of wall shear in the 2-D cases. Here,

$Re_{w}$ for various types of wall shear in the 2-D cases. Here, ![]() $Nu_{0}$ and

$Nu_{0}$ and ![]() $Re_{0}$ are the Nusselt and Reynolds numbers in the absence of wall shear, respectively. The insets magnify

$Re_{0}$ are the Nusselt and Reynolds numbers in the absence of wall shear, respectively. The insets magnify ![]() $Re_{w}$ in the range

$Re_{w}$ in the range ![]() ${100 \leqslant Re_{w} \leqslant 500}$.

${100 \leqslant Re_{w} \leqslant 500}$.

Table 2. Heat transfer efficiency and global flow strength in the 3-D cases. The columns from left to right indicate the following: imposed wall shear type (‘—’ denotes convection without wall shear), cell aspect ratio (![]() $\varGamma _{\perp }$) in the plane perpendicular to the LSC, wall-shear strength (

$\varGamma _{\perp }$) in the plane perpendicular to the LSC, wall-shear strength (![]() $Re_{w}$), Nusselt number (

$Re_{w}$), Nusselt number (![]() $Nu$), Reynolds number (

$Nu$), Reynolds number (![]() $Re$), heat transfer enhancement

$Re$), heat transfer enhancement ![]() $(Nu-Nu_{0})/Nu_{0}$, and global flow strength enhancement

$(Nu-Nu_{0})/Nu_{0}$, and global flow strength enhancement ![]() $(Re-Re_{0})/Re_{0}$. Here,

$(Re-Re_{0})/Re_{0}$. Here, ![]() $Nu_{0}$ and

$Nu_{0}$ and ![]() $Re_{0}$ are the Nusselt and Reynolds numbers in the absence of wall shear at the same

$Re_{0}$ are the Nusselt and Reynolds numbers in the absence of wall shear at the same ![]() $\varGamma _{\perp }$, respectively.

$\varGamma _{\perp }$, respectively.

Figure 5 shows the scaling of the global quantities in 2-D cells, such as ![]() $Nu$ and

$Nu$ and ![]() $Re$, on one of the control parameters

$Re$, on one of the control parameters ![]() $Ra$ (for

$Ra$ (for ![]() $10^{6} \leqslant Ra \leqslant 10^{9}$), whilst the control parameter

$10^{6} \leqslant Ra \leqslant 10^{9}$), whilst the control parameter ![]() $Re_{w}$ is fixed as

$Re_{w}$ is fixed as ![]() $Re_{w}=100$, and

$Re_{w}=100$, and ![]() $Pr$ is fixed as

$Pr$ is fixed as ![]() $Pr=5.3$. We also provide

$Pr=5.3$. We also provide ![]() $Nu$ and

$Nu$ and ![]() $Re$ in the canonical RB convection without shear. Previously, Zhang et al. (Reference Zhang, Zhou and Sun2017) provided tabulated values of

$Re$ in the canonical RB convection without shear. Previously, Zhang et al. (Reference Zhang, Zhou and Sun2017) provided tabulated values of ![]() $Nu$ and

$Nu$ and ![]() $Re$ versus

$Re$ versus ![]() $Ra$ at

$Ra$ at ![]() $Pr = 5.3$. Our simulation results on the canonical RB convection are in good agreement with those reported by Zhang et al. (Reference Zhang, Zhou and Sun2017). The data shown in figure 5 indicate that in the buoyancy-dominated regime (i.e. when

$Pr = 5.3$. Our simulation results on the canonical RB convection are in good agreement with those reported by Zhang et al. (Reference Zhang, Zhou and Sun2017). The data shown in figure 5 indicate that in the buoyancy-dominated regime (i.e. when ![]() $Ra$ is larger at fixed

$Ra$ is larger at fixed ![]() $Re_{w}$), the increase of

$Re_{w}$), the increase of ![]() $Nu$ and

$Nu$ and ![]() $Re$ gradually approaches the power-law relations

$Re$ gradually approaches the power-law relations ![]() $Nu \propto Ra^{0.30}$ and

$Nu \propto Ra^{0.30}$ and ![]() $Re \propto Ra^{0.59}$, consistent with previous results reported in the canonical RB convection (Ciliberto, Cioni & Laroche Reference Ciliberto, Cioni and Laroche1996; van der Poel et al. Reference van der Poel, Stevens, Sugiyama and Lohse2012; Huang & Xia Reference Huang and Xia2016; Zhang et al. Reference Zhang, Zhou and Sun2017; Xu, Chen & Xi Reference Xu, Chen and Xi2021). Overall, the global heat transfer and momentum quantities reveal that the simulated system possesses the key features of turbulent convection in the buoyancy-dominated regime. In the shear-dominated regime (i.e. when

$Re \propto Ra^{0.59}$, consistent with previous results reported in the canonical RB convection (Ciliberto, Cioni & Laroche Reference Ciliberto, Cioni and Laroche1996; van der Poel et al. Reference van der Poel, Stevens, Sugiyama and Lohse2012; Huang & Xia Reference Huang and Xia2016; Zhang et al. Reference Zhang, Zhou and Sun2017; Xu, Chen & Xi Reference Xu, Chen and Xi2021). Overall, the global heat transfer and momentum quantities reveal that the simulated system possesses the key features of turbulent convection in the buoyancy-dominated regime. In the shear-dominated regime (i.e. when ![]() $Ra$ is smaller at fixed

$Ra$ is smaller at fixed ![]() $Re_{w}$), the scaling behaviour of

$Re_{w}$), the scaling behaviour of ![]() $Nu$ and

$Nu$ and ![]() $Re$ with

$Re$ with ![]() $Ra$ deviates significantly from that of the canonical RB convection, suggesting that heat transfer and momentum exchange are not governed solely by the boundary layer.

$Ra$ deviates significantly from that of the canonical RB convection, suggesting that heat transfer and momentum exchange are not governed solely by the boundary layer.

Figure 5. (a) Nusselt number, (b) Reynolds number as functions of Rayleigh number for various types of wall shear in the 2-D cases, when the wall-shear Reynolds number is fixed as ![]() $Re_{w}=100$.

$Re_{w}=100$.

We further investigate quantitatively the influence of different types of wall shear on the temperature distribution. Figure 6 shows the probability density functions (p.d.f.s) of the normalized temperature ![]() $(T-\mu _{T})/\sigma _{T}$ in the bulk region of the 2-D cell (i.e.

$(T-\mu _{T})/\sigma _{T}$ in the bulk region of the 2-D cell (i.e. ![]() $0.4L \leqslant x \leqslant 0.6L$ and

$0.4L \leqslant x \leqslant 0.6L$ and ![]() $0.4H \leqslant y \leqslant 0.6H$), where

$0.4H \leqslant y \leqslant 0.6H$), where ![]() $\mu _{T}$ and

$\mu _{T}$ and ![]() $\sigma _{T}$ are the mean and standard deviation of the temperature. In the absence of wall shear, the p.d.f.s of temperature in the bulk show a stretched exponential behaviour. Under the

$\sigma _{T}$ are the mean and standard deviation of the temperature. In the absence of wall shear, the p.d.f.s of temperature in the bulk show a stretched exponential behaviour. Under the ![]() $(1, 1)$ type wall shear, the temperature in the bulk is well-mixed, and the p.d.f.s are symmetric at different

$(1, 1)$ type wall shear, the temperature in the bulk is well-mixed, and the p.d.f.s are symmetric at different ![]() $Re_{w}$ (see figure 6a). With imposed external wall shear, the p.d.f.s at different

$Re_{w}$ (see figure 6a). With imposed external wall shear, the p.d.f.s at different ![]() $Re_{w}$ collapse, and they deviate significantly from that in the absence of wall shear. The narrowed p.d.f. tails imply that fewer plumes pass through the bulk region and the temperature fluctuation is suppressed. Under the

$Re_{w}$ collapse, and they deviate significantly from that in the absence of wall shear. The narrowed p.d.f. tails imply that fewer plumes pass through the bulk region and the temperature fluctuation is suppressed. Under the ![]() $(2, 1)$ type wall shear, the p.d.f. is negatively skewed at smaller

$(2, 1)$ type wall shear, the p.d.f. is negatively skewed at smaller ![]() $Re_{w}$ (see figure 6b), which is due to cold plumes descending through the central region. However, as

$Re_{w}$ (see figure 6b), which is due to cold plumes descending through the central region. However, as ![]() $Re_{w}$ increases, the skewness of the temperature p.d.f.s decreases, and their tails become narrower, implying that temperature is better mixed and fewer cold fluids pass through the central region. Under the

$Re_{w}$ increases, the skewness of the temperature p.d.f.s decreases, and their tails become narrower, implying that temperature is better mixed and fewer cold fluids pass through the central region. Under the ![]() $(1, 2)$ type wall shear, the p.d.f.s are symmetric (see figure 6c) due to the top-down symmetry of the convection cell, both hot and cold plumes passing through the central region. As the strength of the wall shear increases, the heads of the p.d.f.s gradually exhibit a bi-modal shape (e.g. the inset shown in figure 6c), suggesting that the top cold and bottom hot subregions are gradually separated; meanwhile, all the tails of the p.d.f.s exhibit Gaussian shape, and their profiles collapse for different

$(1, 2)$ type wall shear, the p.d.f.s are symmetric (see figure 6c) due to the top-down symmetry of the convection cell, both hot and cold plumes passing through the central region. As the strength of the wall shear increases, the heads of the p.d.f.s gradually exhibit a bi-modal shape (e.g. the inset shown in figure 6c), suggesting that the top cold and bottom hot subregions are gradually separated; meanwhile, all the tails of the p.d.f.s exhibit Gaussian shape, and their profiles collapse for different ![]() $Re_{w}$. The collapse of the p.d.f. indicates a similar flow pattern in the bulk region because the functional form of the temperature p.d.f. is determined by the coherence of plumes (Solomon & Gollub Reference Solomon and Gollub1990; Xia & Lui Reference Xia and Lui1997).

$Re_{w}$. The collapse of the p.d.f. indicates a similar flow pattern in the bulk region because the functional form of the temperature p.d.f. is determined by the coherence of plumes (Solomon & Gollub Reference Solomon and Gollub1990; Xia & Lui Reference Xia and Lui1997).

Figure 6. The probability density functions (p.d.f.s) of the temperature measured in the bulk region of the 2-D cells (i.e. ![]() $0.4L \leqslant x \leqslant 0.6L$ and

$0.4L \leqslant x \leqslant 0.6L$ and ![]() $0.4H \leqslant y \leqslant 0.6H$) under (a) the

$0.4H \leqslant y \leqslant 0.6H$) under (a) the ![]() $(1, 1)$ type wall shear, (b) the

$(1, 1)$ type wall shear, (b) the ![]() $(2, 1)$ type wall shear, and (c) the

$(2, 1)$ type wall shear, and (c) the ![]() $(1, 2)$ type wall shear, when the flow is in turbulent state. The dot-dashed line represents a Gaussian distribution. The inset in (c) magnifies the head of the p.d.f. at

$(1, 2)$ type wall shear, when the flow is in turbulent state. The dot-dashed line represents a Gaussian distribution. The inset in (c) magnifies the head of the p.d.f. at ![]() $Re_{w}=500$.

$Re_{w}=500$.

We now investigate how the local heat transfer properties are influenced by different types of wall shear. In figure 7, we show the vertical convective heat flux field ![]() $v\,\delta T$, where the temperature fluctuation is

$v\,\delta T$, where the temperature fluctuation is ![]() $\delta T=T-(T_{hot}+T_{cold})/2$. At small wall-shear strength

$\delta T=T-(T_{hot}+T_{cold})/2$. At small wall-shear strength ![]() $Re_{w}=100$ (see figures 7(a–c) for 2-D cases, and 7(g–i) for 3-D cases), the heat is transported mainly by the moving thermal plumes, and the magnitudes of vertical convective heat flux are relatively weak. Under the

$Re_{w}=100$ (see figures 7(a–c) for 2-D cases, and 7(g–i) for 3-D cases), the heat is transported mainly by the moving thermal plumes, and the magnitudes of vertical convective heat flux are relatively weak. Under the ![]() $(1, 1)$ type wall shear (see figures 7a,g), plumes that carry heat mainly go up and down near the sidewalls; under the

$(1, 1)$ type wall shear (see figures 7a,g), plumes that carry heat mainly go up and down near the sidewalls; under the ![]() $(2, 1)$ type wall shear (see figures 7b,h), plumes can also penetrate vertically in the bulk region of the cell, thus forming additional convection channels between the cold top wall and the hot bottom wall; under the

$(2, 1)$ type wall shear (see figures 7b,h), plumes can also penetrate vertically in the bulk region of the cell, thus forming additional convection channels between the cold top wall and the hot bottom wall; under the ![]() $(1, 2)$ type wall shear (see figures 7c,i), plumes that penetrate the bulk region of the cell exhibit horizontal motion at the mid-height of the cell. At large wall-shear strength

$(1, 2)$ type wall shear (see figures 7c,i), plumes that penetrate the bulk region of the cell exhibit horizontal motion at the mid-height of the cell. At large wall-shear strength ![]() $Re_{w} = 4000$ (see figures 7(d–f) for 2-D cases) and

$Re_{w} = 4000$ (see figures 7(d–f) for 2-D cases) and ![]() $Re_{w}=3000$ (see figures 7( j–l) for 3-D cases), the vertical convective heat flux forms much more stable and regular convection channels, and their magnitudes are much stronger. It should be noted that there are small regions of negative convective heat flux immediately adjacent to the regions of large positive convective heat flux, which is known as counter-gradient local heat transport (Gasteuil et al. Reference Gasteuil, Shew, Gibert, Chillà, Castaing and Pinton2007; Huang & Zhou Reference Huang and Zhou2013). The counter-gradient local heat transport essentially describes that both the LSC and the corner flows may contribute to heat transport in the ‘wrong’ direction: hot (or cold) plumes can be brought back to the hot (or cold) plate by either the corner flows or the LSC. The counter-gradient local heat transport is ubiquitous and can be found in 2-D and 3-D systems, either turbulent or laminar states. An interesting finding is that under the

$Re_{w}=3000$ (see figures 7( j–l) for 3-D cases), the vertical convective heat flux forms much more stable and regular convection channels, and their magnitudes are much stronger. It should be noted that there are small regions of negative convective heat flux immediately adjacent to the regions of large positive convective heat flux, which is known as counter-gradient local heat transport (Gasteuil et al. Reference Gasteuil, Shew, Gibert, Chillà, Castaing and Pinton2007; Huang & Zhou Reference Huang and Zhou2013). The counter-gradient local heat transport essentially describes that both the LSC and the corner flows may contribute to heat transport in the ‘wrong’ direction: hot (or cold) plumes can be brought back to the hot (or cold) plate by either the corner flows or the LSC. The counter-gradient local heat transport is ubiquitous and can be found in 2-D and 3-D systems, either turbulent or laminar states. An interesting finding is that under the ![]() $(1, 2)$ type wall shear in the 2-D case (see figure 7f), there exists strong negative vertical convective heat flux along the right vertical wall, which is opposite to the temperature gradient of the system. Under the external wall shear, hot (or cold) fluids are forced to form a circulation in the bottom (or top) subregion of the cell. When the hot (or cold) fluids fall (or rise) along the right vertical wall, they do not exchange heat with the other and do not lose their thermal energy at all, thus hot (or cold) fluids are swept back to the hot (or cold) walls and exhibit counter-gradient heat transport behaviour. Previously, Blass et al. (Reference Blass, Zhu, Verzicco, Lohse and Stevens2020, Reference Blass, Tabak, Verzicco, Stevens and Lohse2021) observed that by adding the Couette-type shear, the increase of heat transfer efficiency is due to elongated streaks generating vertical cross-stream motion, while in our work, adding the

$(1, 2)$ type wall shear in the 2-D case (see figure 7f), there exists strong negative vertical convective heat flux along the right vertical wall, which is opposite to the temperature gradient of the system. Under the external wall shear, hot (or cold) fluids are forced to form a circulation in the bottom (or top) subregion of the cell. When the hot (or cold) fluids fall (or rise) along the right vertical wall, they do not exchange heat with the other and do not lose their thermal energy at all, thus hot (or cold) fluids are swept back to the hot (or cold) walls and exhibit counter-gradient heat transport behaviour. Previously, Blass et al. (Reference Blass, Zhu, Verzicco, Lohse and Stevens2020, Reference Blass, Tabak, Verzicco, Stevens and Lohse2021) observed that by adding the Couette-type shear, the increase of heat transfer efficiency is due to elongated streaks generating vertical cross-stream motion, while in our work, adding the ![]() $(m, n)$ type wall shear mainly facilitates a more coherent flow structure and forms more stable and stronger convection channels, particularly in the cases of laminar flows when the wall-shear strength is strong.

$(m, n)$ type wall shear mainly facilitates a more coherent flow structure and forms more stable and stronger convection channels, particularly in the cases of laminar flows when the wall-shear strength is strong.

Figure 7. Snapshots of vertical convective heat flux field at (a–c) ![]() $Re_{w} = 100$, (d–f)

$Re_{w} = 100$, (d–f) ![]() $Re_{w} = 4000$, (g–i)

$Re_{w} = 4000$, (g–i) ![]() $Re_{w} = 100$ and

$Re_{w} = 100$ and ![]() $\varGamma _{\perp }=1/4$, ( j–l)

$\varGamma _{\perp }=1/4$, ( j–l) ![]() $Re_{w} = 3000$ and

$Re_{w} = 3000$ and ![]() $\varGamma _{\perp }=1/4$, under (a,d,g,j) the

$\varGamma _{\perp }=1/4$, under (a,d,g,j) the ![]() $(1, 1)$ type, (b,e,h,k) the

$(1, 1)$ type, (b,e,h,k) the ![]() $(2, 1)$ type and (c,f,i,l) the

$(2, 1)$ type and (c,f,i,l) the ![]() $(1, 2)$ type wall shear.

$(1, 2)$ type wall shear.

In figure 8, we further plot the p.d.f.s of the vertical convective heat flux ![]() $v\,\delta T$ in the whole cell for 2-D cases. All the p.d.f.s have longer positive tails and shorter negative tails, implying strong upward convective heat transfer, yet there exists counter-gradient convective heat transfer (Huang & Zhou Reference Huang and Zhou2013). Under the wall shear, the strength of the upward convective heat transfer is enhanced with the increase of wall-shear strength in the whole cell; meanwhile, we checked the p.d.f.s of convective heat flux in the bulk region (not shown here for clarity), and found that their shapes are much narrower, implying that heat exchange is weak in the bulk region, and hotter (or colder) fluids tend to flow upwards (or downwards) along the sidewalls. Such strong counter-gradient convective heat transfer is consistent with our qualitative observation shown in figure 7.

$v\,\delta T$ in the whole cell for 2-D cases. All the p.d.f.s have longer positive tails and shorter negative tails, implying strong upward convective heat transfer, yet there exists counter-gradient convective heat transfer (Huang & Zhou Reference Huang and Zhou2013). Under the wall shear, the strength of the upward convective heat transfer is enhanced with the increase of wall-shear strength in the whole cell; meanwhile, we checked the p.d.f.s of convective heat flux in the bulk region (not shown here for clarity), and found that their shapes are much narrower, implying that heat exchange is weak in the bulk region, and hotter (or colder) fluids tend to flow upwards (or downwards) along the sidewalls. Such strong counter-gradient convective heat transfer is consistent with our qualitative observation shown in figure 7.

Figure 8. The p.d.f.s of the heat flux measured in the whole cells for 2-D cases under (a) the ![]() $(1, 1)$ type wall shear, (b) the

$(1, 1)$ type wall shear, (b) the ![]() $(2, 1)$ type wall shear, and (c) the

$(2, 1)$ type wall shear, and (c) the ![]() $(1, 2)$ type wall shear, when the flow is in turbulent state.

$(1, 2)$ type wall shear, when the flow is in turbulent state.

In this work, we designed the ![]() $(m, n)$ type wall shear to facilitate the flow structure with

$(m, n)$ type wall shear to facilitate the flow structure with ![]() $m$ rolls in the

$m$ rolls in the ![]() $x$-direction and

$x$-direction and ![]() $n$ rolls in the

$n$ rolls in the ![]() $y$-direction. Under the imposed wall shear, to evaluate quantitatively whether the expected flow structure is dominated or not, we perform Fourier mode decomposition on the velocity field. Fourier mode decomposition is a powerful tool to extract coherent structure in turbulent convection (Chandra & Verma Reference Chandra and Verma2011, Reference Chandra and Verma2013; Petschel et al. Reference Petschel, Wilczek, Breuer, Friedrich and Hansen2011; Chong et al. Reference Chong, Wagner, Kaczorowski, Shishkina and Xia2018; Wang et al. Reference Wang, Xia, Wang, Sun, Zhou and Wan2018). Specifically, the instantaneous velocity field

$y$-direction. Under the imposed wall shear, to evaluate quantitatively whether the expected flow structure is dominated or not, we perform Fourier mode decomposition on the velocity field. Fourier mode decomposition is a powerful tool to extract coherent structure in turbulent convection (Chandra & Verma Reference Chandra and Verma2011, Reference Chandra and Verma2013; Petschel et al. Reference Petschel, Wilczek, Breuer, Friedrich and Hansen2011; Chong et al. Reference Chong, Wagner, Kaczorowski, Shishkina and Xia2018; Wang et al. Reference Wang, Xia, Wang, Sun, Zhou and Wan2018). Specifically, the instantaneous velocity field ![]() $(u, v)$ is projected onto the Fourier basis

$(u, v)$ is projected onto the Fourier basis ![]() $(\hat {u}^{m,n}, \hat {v}^{m,n})$ as

$(\hat {u}^{m,n}, \hat {v}^{m,n})$ as

Here, the Fourier basis ![]() $(\hat {u}^{m,n}, \hat {v}^{m,n})$ is chosen as

$(\hat {u}^{m,n}, \hat {v}^{m,n})$ is chosen as

The instantaneous amplitude of the Fourier mode is then calculated as

where ![]() $\langle u, \hat {u} \rangle$ and

$\langle u, \hat {u} \rangle$ and ![]() $\langle v, \hat {v} \rangle$ denote the inner products of

$\langle v, \hat {v} \rangle$ denote the inner products of ![]() $u$ and

$u$ and ![]() $\hat {u}$,

$\hat {u}$, ![]() $v$ and

$v$ and ![]() $\hat {v}$, respectively. The energy in each Fourier mode is calculated as

$\hat {v}$, respectively. The energy in each Fourier mode is calculated as ![]() $E^{m,n}(t)=\sqrt {[A_{x}^{m,n}(t)]^{2}+[A_{y}^{m,n}(t)]^{2}}$, the total energy is calculated as

$E^{m,n}(t)=\sqrt {[A_{x}^{m,n}(t)]^{2}+[A_{y}^{m,n}(t)]^{2}}$, the total energy is calculated as ![]() $E_{total}=\sum _{m,n}\langle E^{m,n} \rangle$, and

$E_{total}=\sum _{m,n}\langle E^{m,n} \rangle$, and ![]() $\langle \cdot \rangle$ denotes the time average. In figure 9, we plot the time-averaged energy as functions of

$\langle \cdot \rangle$ denotes the time average. In figure 9, we plot the time-averaged energy as functions of ![]() $Re_{w}$ for various types of wall shear when the flow is in the turbulent state for 2-D cases. Here, we consider

$Re_{w}$ for various types of wall shear when the flow is in the turbulent state for 2-D cases. Here, we consider ![]() $m=1,2$ and

$m=1,2$ and ![]() $n=1, 2$, namely the first four Fourier modes. From figure 9(a), we can see that under the

$n=1, 2$, namely the first four Fourier modes. From figure 9(a), we can see that under the ![]() $(1, 1)$ type wall shear, the

$(1, 1)$ type wall shear, the ![]() $(1, 1)$ Fourier mode is indeed dominant. Similarly, under the

$(1, 1)$ Fourier mode is indeed dominant. Similarly, under the ![]() $(1, 2)$ type wall shear, the

$(1, 2)$ type wall shear, the ![]() $(1, 2)$ Fourier mode is the dominant flow mode (see figure 9c). However, under the

$(1, 2)$ Fourier mode is the dominant flow mode (see figure 9c). However, under the ![]() $(2, 1)$ type wall shear, despite the energy percentage in the

$(2, 1)$ type wall shear, despite the energy percentage in the ![]() $(2, 1)$ mode being much larger compared to that in the absence of wall shear, the

$(2, 1)$ mode being much larger compared to that in the absence of wall shear, the ![]() $(2, 1)$ mode does not contain the highest percentage of energy. We can see from figure 9(b) that the

$(2, 1)$ mode does not contain the highest percentage of energy. We can see from figure 9(b) that the ![]() $(1, 1)$ Fourier mode contains more energy than the expected

$(1, 1)$ Fourier mode contains more energy than the expected ![]() $(2, 1)$ mode. To explain the discrepancy, we check the snapshots of the flow fields and the heat flux fields (see figures 2(b) and 7(b)), and observe that some hot (or cold) plumes lose their energy before reaching the cold top (or hot bottom) wall. The plumes then fall (or turn back up) to form small rolls, thus substructures emerge inside the left-side big roll (Chen et al. Reference Chen, Huang, Xia and Xi2019). When the unstable small rolls inside the left-side big roll shrink their size, the Fourier mode decomposition that captures flows in the bulk region implies that the

$(2, 1)$ mode. To explain the discrepancy, we check the snapshots of the flow fields and the heat flux fields (see figures 2(b) and 7(b)), and observe that some hot (or cold) plumes lose their energy before reaching the cold top (or hot bottom) wall. The plumes then fall (or turn back up) to form small rolls, thus substructures emerge inside the left-side big roll (Chen et al. Reference Chen, Huang, Xia and Xi2019). When the unstable small rolls inside the left-side big roll shrink their size, the Fourier mode decomposition that captures flows in the bulk region implies that the ![]() $(1, 1)$ mode (i.e. one big roll in the whole cell) prevails.

$(1, 1)$ mode (i.e. one big roll in the whole cell) prevails.

Figure 9. Time-averaged energy contained in the first four Fourier modes as functions of ![]() $Re_{w}$ under (a) the

$Re_{w}$ under (a) the ![]() $(1, 1)$ type wall shear, (b) the

$(1, 1)$ type wall shear, (b) the ![]() $(2, 1)$ type wall shear, (c) the

$(2, 1)$ type wall shear, (c) the ![]() $(1, 2)$ type wall shear. Note that the Fourier mode decomposition is applied only when the flow is in a turbulent state for 2-D cases (refer to the phase diagram of flow states in figure 3).

$(1, 2)$ type wall shear. Note that the Fourier mode decomposition is applied only when the flow is in a turbulent state for 2-D cases (refer to the phase diagram of flow states in figure 3).

3.2. Stabilizing thermal turbulence via wall movement

The original objective of imposing the ![]() $(m, n)$ type wall shear is to adjust the internal flow mode and control heat transfer properties, while we found that by increasing the wall-shear strength, the thermal turbulence is relaminarized, and more surprisingly, the heat transfer efficiency of the convection cell in the laminar state is higher than that in the turbulent state. In the previous subsection, we have explained that the enhancement of heat transfer efficiency at the laminar regime is due to the formation of more stable and stronger convection channels. Below, we discuss further the origin of thermal turbulence laminarization. We start by examining the turbulent kinetic energy (TKE) equation of incompressible thermal convection, which is written as

$(m, n)$ type wall shear is to adjust the internal flow mode and control heat transfer properties, while we found that by increasing the wall-shear strength, the thermal turbulence is relaminarized, and more surprisingly, the heat transfer efficiency of the convection cell in the laminar state is higher than that in the turbulent state. In the previous subsection, we have explained that the enhancement of heat transfer efficiency at the laminar regime is due to the formation of more stable and stronger convection channels. Below, we discuss further the origin of thermal turbulence laminarization. We start by examining the turbulent kinetic energy (TKE) equation of incompressible thermal convection, which is written as

\begin{align}

\frac{\partial {\unicode{x1D4C0}}}{\partial t}+\overline{u_{j}}\,\partial_{j}{\unicode{x1D4C0}}

&={-}\overline{u_{i}'u_{j}'}\,\partial_{j} \overline{u_{i}}

\nonumber\\ & \quad

+\partial_{j}\left(-\overline{p'u_{j}'}+\sqrt{\frac{Pr}{Ra}}\,\partial_{j}{\unicode{x1D4C0}}-\frac{1}{2}\,

\overline{u_{i}'u_{i}'u_{j}'}\right)

-\sqrt{\frac{Pr}{Ra}}\,\overline{\left(\partial_{j}u_{i}'

\right)^{2}}+\overline{T'v'}.

\end{align}

\begin{align}

\frac{\partial {\unicode{x1D4C0}}}{\partial t}+\overline{u_{j}}\,\partial_{j}{\unicode{x1D4C0}}

&={-}\overline{u_{i}'u_{j}'}\,\partial_{j} \overline{u_{i}}

\nonumber\\ & \quad