1. Introduction

Climate change is taking place at an unprecedented pace and its impact is being felt across the world with rising sea levels, severe heat waves and more frequent and intense natural disasters (Letelier et al. Reference Letelier, Ulloa, Leyrer and Ortega2023; Liu et al. Reference Liu, He, Wu, Liu, Zhang, Chen, Shen and Li2023). As one of the most pressing environmental issues, climate change is broadly reported to be caused by human activities such as the burning of fossil fuels and deforestation, which lead to critical emissions and buildup of ![]() $\text {CO}_2$ in the atmosphere (Mac Dowell et al. Reference Mac Dowell, Fennell, Shah and Maitland2017; Zhou, Jin & Luo Reference Zhou, Jin and Luo2020; Ren & Kloker Reference Ren and Kloker2022; Hu, Xu & Yang Reference Hu, Xu and Yang2023). Numerous studies have emphasized the necessity of taking immediate actions to reduce global greenhouse gas emissions (primarily

$\text {CO}_2$ in the atmosphere (Mac Dowell et al. Reference Mac Dowell, Fennell, Shah and Maitland2017; Zhou, Jin & Luo Reference Zhou, Jin and Luo2020; Ren & Kloker Reference Ren and Kloker2022; Hu, Xu & Yang Reference Hu, Xu and Yang2023). Numerous studies have emphasized the necessity of taking immediate actions to reduce global greenhouse gas emissions (primarily ![]() $\text {CO}_2$) to meet the

$\text {CO}_2$) to meet the ![]() $1.5\,^\circ {\rm C}$ target of the Paris Agreement (Susskind et al. Reference Susskind, Chun, Goldberg, Gordon, Smith and Zaerpoor2020; Solomon Reference Solomon2023). Therefore, various carbon capture technologies have been developed to separate

$1.5\,^\circ {\rm C}$ target of the Paris Agreement (Susskind et al. Reference Susskind, Chun, Goldberg, Gordon, Smith and Zaerpoor2020; Solomon Reference Solomon2023). Therefore, various carbon capture technologies have been developed to separate ![]() $\text {CO}_2$ from anthropogenic emissions, including chemical absorption, physical adsorption, membrane separation and cryogenic capture (Song et al. Reference Song, Liu, Deng, Li and Kitamura2019; Nocito & Dibenedetto Reference Nocito and Dibenedetto2020; Naquash et al. Reference Naquash, Qyyum, Haider, Bokhari, Lim and Lee2022; Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023).

$\text {CO}_2$ from anthropogenic emissions, including chemical absorption, physical adsorption, membrane separation and cryogenic capture (Song et al. Reference Song, Liu, Deng, Li and Kitamura2019; Nocito & Dibenedetto Reference Nocito and Dibenedetto2020; Naquash et al. Reference Naquash, Qyyum, Haider, Bokhari, Lim and Lee2022; Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023).

Cryogenic carbon capture (CCC), as an innovative technology, cools the industrial flue gas to cryogenic temperatures (usually below ![]() $-100\,^\circ {\rm C}$) and, thus, desublimates the

$-100\,^\circ {\rm C}$) and, thus, desublimates the ![]() $\text {CO}_2$ component. Consequently, the desublimated

$\text {CO}_2$ component. Consequently, the desublimated ![]() $\text {CO}_2$ is separated in pure from other gas components, based on the difference in their freezing points (bin Ab Halim Reference bin Ab Halim2013; Maqsood et al. Reference Maqsood, Mullick, Ali, Kargupta and Ganguly2014). This desublimation-based CCC offers several benefits, including high capture efficiency, low chemical usage and flexible application, which make it hold significant application perspectives and research interests (Babar et al. Reference Babar, Bustam, Ali and Maulud2018, Reference Babar, Mukhtar, Mubashir, Saqib, Ullah, Quddusi, Bustam and Show2021; Font-Palma, Cann & Udemu Reference Font-Palma, Cann and Udemu2021). Although CCC has been successfully tested in several pilot projects, it is still in the nascent stage of commercial applications due to some operational challenges (Pan, Clodic & Toubassy Reference Pan, Clodic and Toubassy2013; Gallucci & van Sint Annaland Reference Gallucci and van Sint Annaland2015). For example, cooling flue gas to extremely low temperatures requires a significant amount of energy, which may make CCC less cost effective than other mature technologies (i.e. chemical absorption and physical adsorption). Low temperatures also have the tendency to cause equipment corrosion. Additionally, inappropriate gas feed rates and heat exchanger units pose risks, such as gas breakthrough, flow channel plug and even premature termination of CCC. Therefore, to address these operational concerns and improve the commercial feasibility of CCC, it is essential to conduct an in-depth investigation of the multiphysics and desublimation kinetics behind CCC.

$\text {CO}_2$ is separated in pure from other gas components, based on the difference in their freezing points (bin Ab Halim Reference bin Ab Halim2013; Maqsood et al. Reference Maqsood, Mullick, Ali, Kargupta and Ganguly2014). This desublimation-based CCC offers several benefits, including high capture efficiency, low chemical usage and flexible application, which make it hold significant application perspectives and research interests (Babar et al. Reference Babar, Bustam, Ali and Maulud2018, Reference Babar, Mukhtar, Mubashir, Saqib, Ullah, Quddusi, Bustam and Show2021; Font-Palma, Cann & Udemu Reference Font-Palma, Cann and Udemu2021). Although CCC has been successfully tested in several pilot projects, it is still in the nascent stage of commercial applications due to some operational challenges (Pan, Clodic & Toubassy Reference Pan, Clodic and Toubassy2013; Gallucci & van Sint Annaland Reference Gallucci and van Sint Annaland2015). For example, cooling flue gas to extremely low temperatures requires a significant amount of energy, which may make CCC less cost effective than other mature technologies (i.e. chemical absorption and physical adsorption). Low temperatures also have the tendency to cause equipment corrosion. Additionally, inappropriate gas feed rates and heat exchanger units pose risks, such as gas breakthrough, flow channel plug and even premature termination of CCC. Therefore, to address these operational concerns and improve the commercial feasibility of CCC, it is essential to conduct an in-depth investigation of the multiphysics and desublimation kinetics behind CCC.

During the operation of the desublimation-based CCC, the flue gas, containing multiple components, flows unsteadily through the void channels among heat exchangers. As the flue gas is cooled and the heat exchanger is heated, ![]() $\text {CO}_2$ is first desublimated and then partially sublimated (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). The intensity of

$\text {CO}_2$ is first desublimated and then partially sublimated (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). The intensity of ![]() $\text {CO}_2$ desublimation and sublimation determines the

$\text {CO}_2$ desublimation and sublimation determines the ![]() $\text {CO}_2$ capture capacity and efficiency of CCC. Therefore, the control of these two aspects (i.e.

$\text {CO}_2$ capture capacity and efficiency of CCC. Therefore, the control of these two aspects (i.e. ![]() $\text {CO}_2$ desublimation and sublimation) is vital in the development of an effective CCC. However, the problem of

$\text {CO}_2$ desublimation and sublimation) is vital in the development of an effective CCC. However, the problem of ![]() $\text {CO}_2$ desublimation and sublimation during CCC incorporates multiple and fully coupled physics, i.e. fluid dynamics, mass transfer mechanisms, conjugate heat transfer between the gas and solid phases, desublimation and sublimation kinetics and solid phase evolutions (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023).

$\text {CO}_2$ desublimation and sublimation during CCC incorporates multiple and fully coupled physics, i.e. fluid dynamics, mass transfer mechanisms, conjugate heat transfer between the gas and solid phases, desublimation and sublimation kinetics and solid phase evolutions (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023).

To understand such a complex problem, experiments have been designed and conducted. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010) proposed a novel CCC system using a dynamically operated packed bed. The carbon capture capacity of the system was experimentally investigated for ![]() $\text {N}_2/\text {CO}_2$ mixtures at atmospheric pressure. However, this system applied a single bed and worked in a discontinuous cycle of three steps: cooling, capture and recovery. To achieve the continuous capture of

$\text {N}_2/\text {CO}_2$ mixtures at atmospheric pressure. However, this system applied a single bed and worked in a discontinuous cycle of three steps: cooling, capture and recovery. To achieve the continuous capture of ![]() $\text {CO}_2$, they further created a CCC system comprising three beds to operate the three steps in parallel (Tuinier, Hamers & van Sint Annaland Reference Tuinier, Hamers and van Sint Annaland2011a; Tuinier, van Sint Annaland & Kuipers Reference Tuinier, van Sint Annaland and Kuipers2011b; Tuinier & van Sint Annaland Reference Tuinier and van Sint Annaland2012). Their experiments showed that a lower initial bed temperature and a higher

$\text {CO}_2$, they further created a CCC system comprising three beds to operate the three steps in parallel (Tuinier, Hamers & van Sint Annaland Reference Tuinier, Hamers and van Sint Annaland2011a; Tuinier, van Sint Annaland & Kuipers Reference Tuinier, van Sint Annaland and Kuipers2011b; Tuinier & van Sint Annaland Reference Tuinier and van Sint Annaland2012). Their experiments showed that a lower initial bed temperature and a higher ![]() $\text {CO}_2$ concentration could reduce the operating cost. For example, the 5 %

$\text {CO}_2$ concentration could reduce the operating cost. For example, the 5 % ![]() $\text {CO}_2$ case yielded a cost of $95.7/

$\text {CO}_2$ case yielded a cost of $95.7/![]() $\text {ton}_{\text {CO}_2}$, which decreased notably to $59.8/

$\text {ton}_{\text {CO}_2}$, which decreased notably to $59.8/![]() $\text {ton}_{\text {CO}_2}$ for the 10 %

$\text {ton}_{\text {CO}_2}$ for the 10 % ![]() $\text {CO}_2$ case. In addition, compared with two competing technologies (i.e. amine absorption and membrane separation), the improved CCC was shown to be the preferred option if a cold source was available at low costs. Nevertheless, these CCC systems were designed to purify flue gases with relatively low

$\text {CO}_2$ case. In addition, compared with two competing technologies (i.e. amine absorption and membrane separation), the improved CCC was shown to be the preferred option if a cold source was available at low costs. Nevertheless, these CCC systems were designed to purify flue gases with relatively low ![]() $\text {CO}_2$ contents (i.e. up to 30 %

$\text {CO}_2$ contents (i.e. up to 30 % ![]() $\text {CO}_2$), and their operations were constrained to the atmospheric pressure. Taking this into account, Ali et al. (Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014, Reference Ali, Maqsood, Redza, Hii, Shariff and Ganguly2016) used the multiple cryogenic desublimation based pipeline network to achieve the removal of

$\text {CO}_2$), and their operations were constrained to the atmospheric pressure. Taking this into account, Ali et al. (Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014, Reference Ali, Maqsood, Redza, Hii, Shariff and Ganguly2016) used the multiple cryogenic desublimation based pipeline network to achieve the removal of ![]() $\text {H}_2\text {O}$ and

$\text {H}_2\text {O}$ and ![]() $\text {CO}_2$ from the natural gas under high

$\text {CO}_2$ from the natural gas under high ![]() $\text {CO}_2$ concentrations and high pressures (i.e. up to 100 %

$\text {CO}_2$ concentrations and high pressures (i.e. up to 100 % ![]() $\text {CO}_2$ and 20 bar).

$\text {CO}_2$ and 20 bar).

Another CCC system based on commercial Stirling coolers (SCs) was developed for gas cooling, ![]() $\text {CO}_2$ desublimation and

$\text {CO}_2$ desublimation and ![]() $\text {CO}_2$ capture, in which multiple SCs were applied to serve as heat exchangers (Song et al. Reference Song, Kitamura, Li and Ogasawara2012b; Song, Kitamura & Li Reference Song, Kitamura and Li2012a; Song et al. Reference Song, Kitamura, Li and Jiang2013; Song, Kitamura & Li Reference Song, Kitamura and Li2014). After extensive experiments on cooling fins of

$\text {CO}_2$ capture, in which multiple SCs were applied to serve as heat exchangers (Song et al. Reference Song, Kitamura, Li and Ogasawara2012b; Song, Kitamura & Li Reference Song, Kitamura and Li2012a; Song et al. Reference Song, Kitamura, Li and Jiang2013; Song, Kitamura & Li Reference Song, Kitamura and Li2014). After extensive experiments on cooling fins of ![]() $15\, {\rm mm}$ length, they suggested the gas feed rate of

$15\, {\rm mm}$ length, they suggested the gas feed rate of ![]() $2\,{\rm L}\,{\rm min}^{-1}$ and the SC temperature of

$2\,{\rm L}\,{\rm min}^{-1}$ and the SC temperature of ![]() $-20\,^\circ {\rm C}$ for the gas cooling stage to obtain the optimal performance (i.e. 85 %

$-20\,^\circ {\rm C}$ for the gas cooling stage to obtain the optimal performance (i.e. 85 % ![]() $\text {CO}_2$ recovery at

$\text {CO}_2$ recovery at ![]() $3.4\,{\rm MJ}\,{\rm kg}_{\text {CO}_2}^{-1}$). Due to the cost and difficulty in achieving extremely low temperatures (i.e. below

$3.4\,{\rm MJ}\,{\rm kg}_{\text {CO}_2}^{-1}$). Due to the cost and difficulty in achieving extremely low temperatures (i.e. below ![]() $-100\,^\circ {\rm C}$), however, optimal operating conditions for the

$-100\,^\circ {\rm C}$), however, optimal operating conditions for the ![]() $\text {CO}_2$ desublimation stage were not determined. In addition to these fixed-bed or fixed-SC CCC systems, the moving-bed CCC system was recently proposed (Willson et al. Reference Willson, Lychnos, Clements, Michailos, Font-Palma, Diego, Pourkashanian and Howe2019; Cann, Font-Palma & Willson Reference Cann, Font-Palma and Willson2021a,Reference Cann, Font-Palma and Willsonb; Font-Palma Reference Font-Palma2021). The packed bed applied moving packing materials to continuously remove materials covered by desublimated

$\text {CO}_2$ desublimation stage were not determined. In addition to these fixed-bed or fixed-SC CCC systems, the moving-bed CCC system was recently proposed (Willson et al. Reference Willson, Lychnos, Clements, Michailos, Font-Palma, Diego, Pourkashanian and Howe2019; Cann, Font-Palma & Willson Reference Cann, Font-Palma and Willson2021a,Reference Cann, Font-Palma and Willsonb; Font-Palma Reference Font-Palma2021). The packed bed applied moving packing materials to continuously remove materials covered by desublimated ![]() $\text {CO}_2$, thus realizing the continuous capture of

$\text {CO}_2$, thus realizing the continuous capture of ![]() $\text {CO}_2$ without introducing multiple packed beds. Experiments were carried out to determine an adequate bed velocity and optimize the carbon capture behaviours.

$\text {CO}_2$ without introducing multiple packed beds. Experiments were carried out to determine an adequate bed velocity and optimize the carbon capture behaviours.

In these existing experiments, the feasibility of various CCC concepts has been validated and the ![]() $\text {CO}_2$ capture performance has been assessed for different operating conditions. Nevertheless, due to the significant operational expenses, only a narrow range of operating parameters were examined in experiments. In light of this limitation, numerical simulations were performed at the same time to investigate the performance of CCC for extensive operating conditions. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010, Reference Tuinier, Hamers and van Sint Annaland2011a) proposed a one-dimensional (1-D) pseudo-homogeneous model to simulate the desublimation and sublimation of

$\text {CO}_2$ capture performance has been assessed for different operating conditions. Nevertheless, due to the significant operational expenses, only a narrow range of operating parameters were examined in experiments. In light of this limitation, numerical simulations were performed at the same time to investigate the performance of CCC for extensive operating conditions. Tuinier et al. (Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010, Reference Tuinier, Hamers and van Sint Annaland2011a) proposed a one-dimensional (1-D) pseudo-homogeneous model to simulate the desublimation and sublimation of ![]() $\text {CO}_2$. By comparing with experiments, they determined the mass transfer rate constant for

$\text {CO}_2$. By comparing with experiments, they determined the mass transfer rate constant for ![]() $\text {CO}_2$ desublimation and sublimation. Their numerical results confirmed the experimental observation that the desublimation of

$\text {CO}_2$ desublimation and sublimation. Their numerical results confirmed the experimental observation that the desublimation of ![]() $\text {CO}_2$ raised the bed temperature to an equilibrium level of

$\text {CO}_2$ raised the bed temperature to an equilibrium level of ![]() $-(93\unicode{x2013}98)\,^\circ {\rm C}$. They also demonstrated that an initial bed temperature above the threshold of

$-(93\unicode{x2013}98)\,^\circ {\rm C}$. They also demonstrated that an initial bed temperature above the threshold of ![]() $-120\,^\circ {\rm C}$ could exponentially reduce the amount of

$-120\,^\circ {\rm C}$ could exponentially reduce the amount of ![]() $\text {CO}_2$ captured (Tuinier et al. Reference Tuinier, van Sint Annaland and Kuipers2011b). For instance, for a fed mixture with 10 %

$\text {CO}_2$ captured (Tuinier et al. Reference Tuinier, van Sint Annaland and Kuipers2011b). For instance, for a fed mixture with 10 % ![]() $\text {CO}_2$, the increased bed temperature from

$\text {CO}_2$, the increased bed temperature from ![]() $-120\,^\circ {\rm C}$ to

$-120\,^\circ {\rm C}$ to ![]() $-110\,^\circ {\rm C}$ could diminish the recovered

$-110\,^\circ {\rm C}$ could diminish the recovered ![]() $\text {CO}_2$ from 90 % to 12 %. By introducing a new mass transfer scheme, this 1-D model was improved to consider both the

$\text {CO}_2$ from 90 % to 12 %. By introducing a new mass transfer scheme, this 1-D model was improved to consider both the ![]() $\text {CO}_2$ desublimation on the gas–solid interface and the

$\text {CO}_2$ desublimation on the gas–solid interface and the ![]() $\text {CO}_2$ nucleation inside the gas phase (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). This improved model was able to evaluate the

$\text {CO}_2$ nucleation inside the gas phase (Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019). This improved model was able to evaluate the ![]() $\text {CO}_2$ capture capacity, predict operating risks (e.g. chocking), and identify the saturation point between capture and recovery steps. This 1-D model was recently extended to consider the energy balance for moving heat exchangers (Cann & Font-Palma Reference Cann and Font-Palma2023).

$\text {CO}_2$ capture capacity, predict operating risks (e.g. chocking), and identify the saturation point between capture and recovery steps. This 1-D model was recently extended to consider the energy balance for moving heat exchangers (Cann & Font-Palma Reference Cann and Font-Palma2023).

On the other hand, a two-dimensional (2-D) quasi-steady model was developed to solve the heat and mass transfer during the desublimation and sublimation of ![]() $\text {CO}_2$ (Song et al. Reference Song, Kitamura, Li and Ogasawara2012b,Reference Song, Kitamura and Lia). The frosted

$\text {CO}_2$ (Song et al. Reference Song, Kitamura, Li and Ogasawara2012b,Reference Song, Kitamura and Lia). The frosted ![]() $\text {CO}_2$ layer was found to enhance the heat resistance and increase the frost surface temperature. For instance, as the frost thickness increased from

$\text {CO}_2$ layer was found to enhance the heat resistance and increase the frost surface temperature. For instance, as the frost thickness increased from ![]() $0\, {\rm mm}$ to

$0\, {\rm mm}$ to ![]() $3\, {\rm mm}$, the thermal conductivity of frost escalated from 0 to

$3\, {\rm mm}$, the thermal conductivity of frost escalated from 0 to ![]() $0.4\, {\rm W}\,{\rm mK}^{-1}$ and the temperature rose from

$0.4\, {\rm W}\,{\rm mK}^{-1}$ and the temperature rose from ![]() $-106.3\,^\circ {\rm C}$ to

$-106.3\,^\circ {\rm C}$ to ![]() $-98\,^\circ {\rm C}$ (Song et al. Reference Song, Kitamura, Li and Jiang2013). This 2-D model was then advanced to consider heat integration, membrane capture, pressure recovery and cold thermal energy utilization units, showing the decreased energy consumption of these improved CCC systems (Song et al. Reference Song, Liu, Ji, Deng, Zhao and Kitamura2017a,Reference Song, Liu, Ji, Deng, Zhao, Li and Kitamurab; Sun et al. Reference Sun, Tian, Song, Deng, Shi, Kang and Shu2021). It is emphasized that the above 1-D and 2-D models were based on a unified velocity profile and ignored impacts of the unsteady gas flow. Consequently, a 1-D transient model was proposed to reveal the detailed

$-98\,^\circ {\rm C}$ (Song et al. Reference Song, Kitamura, Li and Jiang2013). This 2-D model was then advanced to consider heat integration, membrane capture, pressure recovery and cold thermal energy utilization units, showing the decreased energy consumption of these improved CCC systems (Song et al. Reference Song, Liu, Ji, Deng, Zhao and Kitamura2017a,Reference Song, Liu, Ji, Deng, Zhao, Li and Kitamurab; Sun et al. Reference Sun, Tian, Song, Deng, Shi, Kang and Shu2021). It is emphasized that the above 1-D and 2-D models were based on a unified velocity profile and ignored impacts of the unsteady gas flow. Consequently, a 1-D transient model was proposed to reveal the detailed ![]() $\text {CO}_2$ desublimation characteristics, with the unsteady gas flow, mass transfer and energy conservation being included (Wang et al. Reference Wang, Pfotenhauer, Zhi, Qiu and Li2018a). The model was validated by experimental data and exhibited improved accuracy when incorporating the desublimated solid

$\text {CO}_2$ desublimation characteristics, with the unsteady gas flow, mass transfer and energy conservation being included (Wang et al. Reference Wang, Pfotenhauer, Zhi, Qiu and Li2018a). The model was validated by experimental data and exhibited improved accuracy when incorporating the desublimated solid ![]() $\text {CO}_2$ layer (SCL) in an annular tube. In addition, the lower gas feed rate and the higher

$\text {CO}_2$ layer (SCL) in an annular tube. In addition, the lower gas feed rate and the higher ![]() $\text {CO}_2$ concentration were found to yield the higher carbon capture rate (e.g. the

$\text {CO}_2$ concentration were found to yield the higher carbon capture rate (e.g. the ![]() $\text {CO}_2$ capture rate was upgraded from 40 % for

$\text {CO}_2$ capture rate was upgraded from 40 % for ![]() $1800\,{\rm ml}\,{\rm s}^{-1}$ to 100 % for

$1800\,{\rm ml}\,{\rm s}^{-1}$ to 100 % for ![]() $300\, {\rm ml}\,{\rm s}^{-1}$).

$300\, {\rm ml}\,{\rm s}^{-1}$).

These existing models have simulated the desublimation and sublimation properties of ![]() $\text {CO}_2$, and evaluated the carbon capture performance of CCC for a certain range of operating conditions. Despite these achievements, the limitations of either 1-D or quasi-steady assumptions make existing models inadequate in capturing the multiple physics and complex interactions behind CCC. In addition, these existing models were constructed on volume-averaged scales. As a result, intricate structures of the desublimated

$\text {CO}_2$, and evaluated the carbon capture performance of CCC for a certain range of operating conditions. Despite these achievements, the limitations of either 1-D or quasi-steady assumptions make existing models inadequate in capturing the multiple physics and complex interactions behind CCC. In addition, these existing models were constructed on volume-averaged scales. As a result, intricate structures of the desublimated ![]() $\text {CO}_2$ at the pore scale were ignored, conjugate heat transfer between the gas and solid phases was simplified, the random growth and consumption of desublimated

$\text {CO}_2$ at the pore scale were ignored, conjugate heat transfer between the gas and solid phases was simplified, the random growth and consumption of desublimated ![]() $\text {CO}_2$ were neglected, and the porous structure of the packed bed was disregarded. Furthermore, in previous numerical studies, heat and mass transfer coefficients were estimated by empirical correlations, the accuracy of which depends on a prior pore-scale knowledge base (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a,Reference Xu, Long, Jiang, Zan, Huang, Chen and Shib, Reference Xu, Dai, Yang, Liu and Shi2022). Therefore, a pore-scale model is crucial for a comprehensive study of

$\text {CO}_2$ were neglected, and the porous structure of the packed bed was disregarded. Furthermore, in previous numerical studies, heat and mass transfer coefficients were estimated by empirical correlations, the accuracy of which depends on a prior pore-scale knowledge base (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a,Reference Xu, Long, Jiang, Zan, Huang, Chen and Shib, Reference Xu, Dai, Yang, Liu and Shi2022). Therefore, a pore-scale model is crucial for a comprehensive study of ![]() $\text {CO}_2$ desublimation and sublimation during CCC, which is currently missing.

$\text {CO}_2$ desublimation and sublimation during CCC, which is currently missing.

Over the past three decades, the lattice Boltzmann (LB) method has been extensively developed for simulating complex fluid flows with phase change and chemical reactions at the pore scale (Li et al. Reference Li, Luo, Kang, He, Chen and Liu2016; Lei, Luo & Wu Reference Lei, Luo and Wu2019; Chen et al. Reference Chen, He, Zhao, Kang, Li, Carmeliet, Shikazono and Tao2022; Sawant, Dorschner & Karlin Reference Sawant, Dorschner and Karlin2022). Accordingly, there exist plentiful LB models for separately investigating the multiple physics behind ![]() $\text {CO}_2$ desublimation and sublimation at the pore scale, including the unsteady fluid flow (Wang et al. Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2018b; Shi, Wu & Shan Reference Shi, Wu and Shan2021; Li & Shan Reference Li and Shan2023), species transport (Sawant, Dorschner & Karlin Reference Sawant, Dorschner and Karlin2021), conjugate heat transfer (Karani & Huber Reference Karani and Huber2015; He et al. Reference He, Liu, Li and Tao2019), reactive fluid–solid interface (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012, Reference Zhang, Zhang, Zhang, Zhang, Yao, Sun and Yang2019) and solid structure evolution (Chen et al. Reference Chen, Kang, Carey and Tao2014, Reference Chen, Zhang, Kang and Tao2020). However, the combination and interactions of these complex physics have not been achieved by a single LB model, which is indeed challenging.

$\text {CO}_2$ desublimation and sublimation at the pore scale, including the unsteady fluid flow (Wang et al. Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2018b; Shi, Wu & Shan Reference Shi, Wu and Shan2021; Li & Shan Reference Li and Shan2023), species transport (Sawant, Dorschner & Karlin Reference Sawant, Dorschner and Karlin2021), conjugate heat transfer (Karani & Huber Reference Karani and Huber2015; He et al. Reference He, Liu, Li and Tao2019), reactive fluid–solid interface (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012, Reference Zhang, Zhang, Zhang, Zhang, Yao, Sun and Yang2019) and solid structure evolution (Chen et al. Reference Chen, Kang, Carey and Tao2014, Reference Chen, Zhang, Kang and Tao2020). However, the combination and interactions of these complex physics have not been achieved by a single LB model, which is indeed challenging.

To fill this gap, we recently formulated a pore-scale CCC modelling framework based on the LB method, incorporating the unsteady gas flow, conjugate heat transfer, desublimation kinetics and solid ![]() $\text {CO}_2$ generation (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023). The model was successfully applied to identify different

$\text {CO}_2$ generation (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023). The model was successfully applied to identify different ![]() $\text {CO}_2$ desublimation regimes, albeit constrained to a single packing material and fixed packing temperatures. In this work, the LB model is extended to incorporate both

$\text {CO}_2$ desublimation regimes, albeit constrained to a single packing material and fixed packing temperatures. In this work, the LB model is extended to incorporate both ![]() $\text {CO}_2$ desublimation and sublimation in a packed bed, considering the consumption of solid

$\text {CO}_2$ desublimation and sublimation in a packed bed, considering the consumption of solid ![]() $\text {CO}_2$ as the packed bed is heated. By evaluating the carbon capture performance for different operating conditions, this study aims to improve the understanding of CCC and shed light on the optimal operating conditions.

$\text {CO}_2$ as the packed bed is heated. By evaluating the carbon capture performance for different operating conditions, this study aims to improve the understanding of CCC and shed light on the optimal operating conditions.

2. Physical and mathematical models

The operation of CCC in a packed bed is schematically depicted in figure 1(a), which follows a circle of three steps: cooling, capture and recovery (Tuinier et al. Reference Tuinier, van Sint Annaland and Kuipers2011b; Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014; Babar et al. Reference Babar, Mukhtar, Mubashir, Saqib, Ullah, Quddusi, Bustam and Show2021). During the cooling step, a refrigerant (e.g. refrigerated ![]() $\text {N}_2$, cleaned flue gas, evaporated liquified natural gas) feeds into the packed bed and cools packing materials below the freezing point of

$\text {N}_2$, cleaned flue gas, evaporated liquified natural gas) feeds into the packed bed and cools packing materials below the freezing point of ![]() $\text {CO}_2$. The refrigerant exits the bed after the cooling process, and it can either be released into the atmosphere or recycled to the bed inlet via a cooler. Then, the CCC system enters the capture step and the feed is switched to the warm flue gas. In the cooled packed bed the component

$\text {CO}_2$. The refrigerant exits the bed after the cooling process, and it can either be released into the atmosphere or recycled to the bed inlet via a cooler. Then, the CCC system enters the capture step and the feed is switched to the warm flue gas. In the cooled packed bed the component ![]() $\text {CO}_2$ is desublimated and a front of the desublimated

$\text {CO}_2$ is desublimated and a front of the desublimated ![]() $\text {CO}_2$ (or desublimation front,

$\text {CO}_2$ (or desublimation front, ![]() $l_d$) is formed. Meanwhile, as the packing grains are heated by the warm flue gas, previously desublimated

$l_d$) is formed. Meanwhile, as the packing grains are heated by the warm flue gas, previously desublimated ![]() $\text {CO}_2$ is sublimated to form a sublimation front (

$\text {CO}_2$ is sublimated to form a sublimation front (![]() $l_s$) behind

$l_s$) behind ![]() $l_d$. Once the fed

$l_d$. Once the fed ![]() $\text {CO}_2$ starts to leave the bed outlet, the packed bed becomes saturated and the recovery step begins. The feed is changed to the warm

$\text {CO}_2$ starts to leave the bed outlet, the packed bed becomes saturated and the recovery step begins. The feed is changed to the warm ![]() $\text {CO}_2$ gas, which promotes the continuous sublimation of solid

$\text {CO}_2$ gas, which promotes the continuous sublimation of solid ![]() $\text {CO}_2$. The sublimated

$\text {CO}_2$. The sublimated ![]() $\text {CO}_2$ exits the bed and is collected for cycling or subsequent applications. Once all the solid

$\text {CO}_2$ exits the bed and is collected for cycling or subsequent applications. Once all the solid ![]() $\text {CO}_2$ is recovered, the CCC system returns to the cooling step. The

$\text {CO}_2$ is recovered, the CCC system returns to the cooling step. The ![]() $\text {CO}_2$ capture and recovery steps usually have a longer duration compared with the cooling period.

$\text {CO}_2$ capture and recovery steps usually have a longer duration compared with the cooling period.

Figure 1. The schematic descriptions of (a) the operation of CCC in a packed bed and (b) the underlying multiple physics.

In the cooling step, CCC is dominated by the heat transfer between the refrigerant and the packing materials, with no separation of ![]() $\text {CO}_2$ being introduced. During the following capture and recovery of

$\text {CO}_2$ being introduced. During the following capture and recovery of ![]() $\text {CO}_2$, the more complex and fully coupled multiphysics takes part and must be considered. On the one hand, the multicomponent gas flow in channels and conjugate heat transfer between the gas and solid phases (i.e. solid packing materials and solid

$\text {CO}_2$, the more complex and fully coupled multiphysics takes part and must be considered. On the one hand, the multicomponent gas flow in channels and conjugate heat transfer between the gas and solid phases (i.e. solid packing materials and solid ![]() $\text {CO}_2$) are introduced. On the other hand, the desublimation and sublimation of

$\text {CO}_2$) are introduced. On the other hand, the desublimation and sublimation of ![]() $\text {CO}_2$ take place and modify the solid structure, multicomponent gas flow and gas compositions. Meanwhile,

$\text {CO}_2$ take place and modify the solid structure, multicomponent gas flow and gas compositions. Meanwhile, ![]() $\text {CO}_2$ desublimation and sublimation are exothermic and endothermic, respectively, thus affecting the heat transfer. Such changes in the local

$\text {CO}_2$ desublimation and sublimation are exothermic and endothermic, respectively, thus affecting the heat transfer. Such changes in the local ![]() $\text {CO}_2$ composition and temperature, in turn, control the desublimation and sublimation rates. Therefore, the multicomponent gas flow, conjugate heat transfer, solid structure evolution and desublimation and sublimation kinetics are fully coupled. The interactions of these multiple physics are sketched in figure 1(b). Considering that the

$\text {CO}_2$ composition and temperature, in turn, control the desublimation and sublimation rates. Therefore, the multicomponent gas flow, conjugate heat transfer, solid structure evolution and desublimation and sublimation kinetics are fully coupled. The interactions of these multiple physics are sketched in figure 1(b). Considering that the ![]() $\text {CO}_2$ capture performance of CCC is mainly determined by the desublimation and sublimation of

$\text {CO}_2$ capture performance of CCC is mainly determined by the desublimation and sublimation of ![]() $\text {CO}_2$, this study focuses on the capture and recovery steps.

$\text {CO}_2$, this study focuses on the capture and recovery steps.

Before constructing governing equations for describing the desublimation and sublimation of ![]() $\text {CO}_2$ during CCC at the pore scale, some simplifications and assumptions are made as follows: (1) this work investigates the capture and recovery of

$\text {CO}_2$ during CCC at the pore scale, some simplifications and assumptions are made as follows: (1) this work investigates the capture and recovery of ![]() $\text {CO}_2$ without detailing the cooling of packing materials; (2) the flue gas, treated as a mixture of

$\text {CO}_2$ without detailing the cooling of packing materials; (2) the flue gas, treated as a mixture of ![]() $\text {CO}_2$ and

$\text {CO}_2$ and ![]() $\text {N}_2$, obeys the ideal gas law and is incompressible and neutrally buoyant; (3) Fick's law is applied to describe the species mass diffusion; (4) the mass transfer rate of

$\text {N}_2$, obeys the ideal gas law and is incompressible and neutrally buoyant; (3) Fick's law is applied to describe the species mass diffusion; (4) the mass transfer rate of ![]() $\text {CO}_2$ desublimation and sublimation is proportional to the local deviation from the gas–solid equilibrium; (5) physical properties of the gas and the solid phases are set as constants in relation to the initial condition; and (6) a cryogenic bed packed with multiple grains of a uniform diameter is considered, the movement of packing grains are neglected, and the bed porosity equals the experimental value (Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014).

$\text {CO}_2$ desublimation and sublimation is proportional to the local deviation from the gas–solid equilibrium; (5) physical properties of the gas and the solid phases are set as constants in relation to the initial condition; and (6) a cryogenic bed packed with multiple grains of a uniform diameter is considered, the movement of packing grains are neglected, and the bed porosity equals the experimental value (Ali et al. Reference Ali, Maqsood, Syahera, Shariff and Ganguly2014).

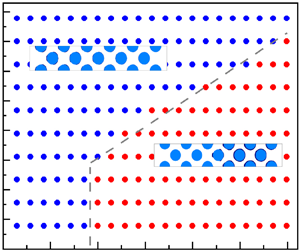

Under these premises, a sample cryogenic packed bed with porosity ![]() $\psi$ is depicted in figure 2(a). The computational domain is

$\psi$ is depicted in figure 2(a). The computational domain is ![]() $0 \leq x \leq l_x$ and

$0 \leq x \leq l_x$ and ![]() $0 \leq y \leq l_y$, wherein a staggered array of circular grains with a uniform diameter

$0 \leq y \leq l_y$, wherein a staggered array of circular grains with a uniform diameter ![]() $d$ is encompassed. From the bed inlet, the incompressible flue gas is injected at temperature

$d$ is encompassed. From the bed inlet, the incompressible flue gas is injected at temperature ![]() $T_0$, pressure

$T_0$, pressure ![]() $p_0$ and velocity

$p_0$ and velocity ![]() $\boldsymbol {u}_0$. Initially, the flue gas consists of

$\boldsymbol {u}_0$. Initially, the flue gas consists of ![]() $\text {CO}_2$ and

$\text {CO}_2$ and ![]() $\text {N}_2$, having mass fractions

$\text {N}_2$, having mass fractions ![]() $Y_0$ and

$Y_0$ and ![]() $(1-Y_0)$, respectively. The temperature of packing grains is set to

$(1-Y_0)$, respectively. The temperature of packing grains is set to ![]() $T_{w}$ at first, which is above the freezing point of

$T_{w}$ at first, which is above the freezing point of ![]() $\text {N}_2$ but below that of

$\text {N}_2$ but below that of ![]() $\text {CO}_2$. Hence, after injection,

$\text {CO}_2$. Hence, after injection, ![]() $\text {N}_2$ flows through the domain without phase change, while

$\text {N}_2$ flows through the domain without phase change, while ![]() $\text {CO}_2$ is partially desublimated to form an SCL on the surface of the packing grains. The

$\text {CO}_2$ is partially desublimated to form an SCL on the surface of the packing grains. The ![]() $\text {CO}_2$ desublimation is exothermic and expressed as

$\text {CO}_2$ desublimation is exothermic and expressed as

Here, ![]() $Q_d$ is the heat released from

$Q_d$ is the heat released from ![]() $\text {CO}_2$ desublimation, and the gas and solid phases of

$\text {CO}_2$ desublimation, and the gas and solid phases of ![]() $\text {CO}_2$ are denoted by

$\text {CO}_2$ are denoted by ![]() $g$ and

$g$ and ![]() $s$, respectively.

$s$, respectively.

Figure 2. The schematic diagrams of (a) the cryogenic packed bed for simulation and (b) ![]() $\text {CO}_2$ desublimation and sublimation on a single packing grain at the pore scale.

$\text {CO}_2$ desublimation and sublimation on a single packing grain at the pore scale.

Due to the exothermic desublimation process and the heat transfer between the gas stream and solid packing grains, the temperature of the solid phases is locally raised to the freezing point of ![]() $\text {CO}_2$. Consequently, the captured SCL starts to sublimate as

$\text {CO}_2$. Consequently, the captured SCL starts to sublimate as

Both the ![]() $\text {CO}_2$ desublimation and the incoming warm flue gas contribute to the heat

$\text {CO}_2$ desublimation and the incoming warm flue gas contribute to the heat ![]() $Q_s$ for sublimation.

$Q_s$ for sublimation.

For such desublimation and sublimation processes, the mass transfer rate between the gaseous ![]() $\text {CO}_2$ and the solid

$\text {CO}_2$ and the solid ![]() $\text {CO}_2$ is estimated as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010; Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019)

$\text {CO}_2$ is estimated as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010; Debnath et al. Reference Debnath, Mukherjee, Mullick, Ghoshdastidar, Ganguly and Kargupta2019)

\begin{equation} m_r = \begin{cases} k_r \left( y_i p - p_e \right) & \text{if} \ \left(y_i p > p_e, y_i > 0\right),\\ k_r \left( y_i p - p_e \right)A & \text{if} \ \left(y_i p < p_e, A = \dfrac{m_i}{m_i+0.1} > 0\right),\\ 0 & \text{if} \ \{ \left(y_i p > p_e, \ y_i = 0\right) \ \text{or} \ \left(y_i p < p_e, A = 0\right)\}. \end{cases} \end{equation}

\begin{equation} m_r = \begin{cases} k_r \left( y_i p - p_e \right) & \text{if} \ \left(y_i p > p_e, y_i > 0\right),\\ k_r \left( y_i p - p_e \right)A & \text{if} \ \left(y_i p < p_e, A = \dfrac{m_i}{m_i+0.1} > 0\right),\\ 0 & \text{if} \ \{ \left(y_i p > p_e, \ y_i = 0\right) \ \text{or} \ \left(y_i p < p_e, A = 0\right)\}. \end{cases} \end{equation}

Depending on the sign of ![]() $m_r$, either

$m_r$, either ![]() $\text {CO}_2$ desublimation (

$\text {CO}_2$ desublimation (![]() $m_r>0$) or

$m_r>0$) or ![]() $\text {CO}_2$ sublimation (

$\text {CO}_2$ sublimation (![]() $m_r<0$) occurs. Here,

$m_r<0$) occurs. Here, ![]() $k_r$ is the mass desublimation rate constant,

$k_r$ is the mass desublimation rate constant, ![]() $m_i$ is the mass of desublimated

$m_i$ is the mass of desublimated ![]() ${\text {CO}_2}$ per unit volume and

${\text {CO}_2}$ per unit volume and ![]() $p$ is the flue gas pressure. The mole fraction of

$p$ is the flue gas pressure. The mole fraction of ![]() ${\text {CO}_2}$ is calculated as

${\text {CO}_2}$ is calculated as

where ![]() $Y$ is the mass fraction of

$Y$ is the mass fraction of ![]() $\text {CO}_2$ in the flue gas. Here

$\text {CO}_2$ in the flue gas. Here ![]() $M$,

$M$, ![]() $M_{\text {CO}_2}$ and

$M_{\text {CO}_2}$ and ![]() $M_{\text {N}_2}$ are molecular weights of the flue gas,

$M_{\text {N}_2}$ are molecular weights of the flue gas, ![]() $\text {CO}_2$ and

$\text {CO}_2$ and ![]() $\text {N}_2$, respectively. In (2.3), for the mass transfer rate

$\text {N}_2$, respectively. In (2.3), for the mass transfer rate ![]() $m_r$, the equilibrium pressure between the gas and the solid phases corresponding to the local temperature

$m_r$, the equilibrium pressure between the gas and the solid phases corresponding to the local temperature ![]() $T$ is determined by an empirical correlation as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010)

$T$ is determined by an empirical correlation as (Tuinier et al. Reference Tuinier, van Sint Annaland, Kramer and Kuipers2010)

The units of ![]() $p_e$ and

$p_e$ and ![]() $T$ are Pascal (

$T$ are Pascal (![]() $\mbox {Pa}$) and Kelvin (

$\mbox {Pa}$) and Kelvin (![]() $\mbox {K}$), respectively.

$\mbox {K}$), respectively.

From the desublimation and sublimation processes, the released heat ![]() $Q_d$ and the absorbed heat

$Q_d$ and the absorbed heat ![]() $Q_s$ are calculated as

$Q_s$ are calculated as

with ![]() $h_r$ being the enthalpy change of

$h_r$ being the enthalpy change of ![]() $\text {CO}_2$ desublimation and

$\text {CO}_2$ desublimation and ![]() $a_r$ being the specific surface area per unit volume. Details on the calculation of

$a_r$ being the specific surface area per unit volume. Details on the calculation of ![]() $a_r$ and its sensitivity are provided in the supplementary material available at https://doi.org/10.1017/jfm.2024.351. By using (2.6), either

$a_r$ and its sensitivity are provided in the supplementary material available at https://doi.org/10.1017/jfm.2024.351. By using (2.6), either ![]() $Q_d$ for desublimation (

$Q_d$ for desublimation (![]() $m_r>0$) or

$m_r>0$) or ![]() $Q_s$ for sublimation (

$Q_s$ for sublimation (![]() $m_r<0$) can be calculated. During

$m_r<0$) can be calculated. During ![]() $\text {CO}_2$ desublimation and sublimation, the pore structure of the solid phases changes with the generation and consumption of SCL on the surface of the packing grains. This structure evolution is tracked by the mass balance equation for the solid

$\text {CO}_2$ desublimation and sublimation, the pore structure of the solid phases changes with the generation and consumption of SCL on the surface of the packing grains. This structure evolution is tracked by the mass balance equation for the solid ![]() $\text {CO}_2$ as (Kang et al. Reference Kang, Chen, Valocchi and Viswanathan2014)

$\text {CO}_2$ as (Kang et al. Reference Kang, Chen, Valocchi and Viswanathan2014)

where ![]() $V_s$ and

$V_s$ and ![]() $\rho _s$ represent the volume and density of solid

$\rho _s$ represent the volume and density of solid ![]() $\text {CO}_2$, respectively, and

$\text {CO}_2$, respectively, and ![]() $V_r$ is the active volume for desublimation.

$V_r$ is the active volume for desublimation.

From the mass transfer scheme in (2.3), the following three scenarios may occur at the interface between the gas and solid phases ![]() $I$.

$I$.

(i) At the interface

$I_d$, the partial pressure and mass fraction of the component

$I_d$, the partial pressure and mass fraction of the component  $\text {CO}_2$ satisfy the criterion (

$\text {CO}_2$ satisfy the criterion ( $y_i p > p_e$,

$y_i p > p_e$,  $y_i>0$). So,

$y_i>0$). So,  $m_r$ is positive (i.e.

$m_r$ is positive (i.e.  $m_r>0$) and

$m_r>0$) and  $\text {CO}_2$ desublimation takes place. During this process, gaseous

$\text {CO}_2$ desublimation takes place. During this process, gaseous  $\text {CO}_2$ is consumed, heat

$\text {CO}_2$ is consumed, heat  $Q_d$ is released and SCL is generated.

$Q_d$ is released and SCL is generated.(ii) At the interface

$I_s$ satisfying the criterion (

$I_s$ satisfying the criterion ( $y_i p < p_e$,

$y_i p < p_e$,  $A>0$),

$A>0$),  $m_r$ becomes less than 0 (i.e.

$m_r$ becomes less than 0 (i.e.  $m_r<0$) and SCL is sublimated to produce gaseous

$m_r<0$) and SCL is sublimated to produce gaseous  $\text {CO}_2$. Such a process brings about the generation of gaseous

$\text {CO}_2$. Such a process brings about the generation of gaseous  $\text {CO}_2$, the absorption of heat

$\text {CO}_2$, the absorption of heat  $Q_s$ and the consumption of the SCL.

$Q_s$ and the consumption of the SCL.(iii) At the interface

$I_n$ with (

$I_n$ with ( $y_i p > p_e$,

$y_i p > p_e$,  $y_i=0$) or (

$y_i=0$) or ( $y_i p < p_e$,

$y_i p < p_e$,  $A=0$),

$A=0$),  $m_r$ equals 0. Thus, neither the desublimation nor sublimation of

$m_r$ equals 0. Thus, neither the desublimation nor sublimation of  $\text {CO}_2$ happens.

$\text {CO}_2$ happens.

Note that the calculation of ![]() $m_r$ in (2.3) can be conveniently replaced by other expressions if necessary. In this study,

$m_r$ in (2.3) can be conveniently replaced by other expressions if necessary. In this study, ![]() $I_{d, s}$ (i.e.

$I_{d, s}$ (i.e. ![]() $I_d$ and

$I_d$ and ![]() $I_s$) and

$I_s$) and ![]() $I_n$ are referred to as active and inactive boundaries, respectively.

$I_n$ are referred to as active and inactive boundaries, respectively.

Based on the above assumptions and definitions, a set of governing equations is built up to model the desublimation and sublimation of ![]() ${\text {CO}_2}$ during CCC at the pore scale. That includes the continuity equation (2.8), the incompressible Navier–Stokes equation (2.9) and the component conservation equation (2.10) for the flue gas stream in flow paths, as well as the energy balance equation (2.11) for heat transfer in both flow paths (i.e. flue gas) and solid phases (i.e. solid packing materials and solid

${\text {CO}_2}$ during CCC at the pore scale. That includes the continuity equation (2.8), the incompressible Navier–Stokes equation (2.9) and the component conservation equation (2.10) for the flue gas stream in flow paths, as well as the energy balance equation (2.11) for heat transfer in both flow paths (i.e. flue gas) and solid phases (i.e. solid packing materials and solid ![]() $\text {CO}_2$). These equations are expressed as follows:

$\text {CO}_2$). These equations are expressed as follows:

Here, ![]() $\boldsymbol {u}=(u,\ v)$,

$\boldsymbol {u}=(u,\ v)$, ![]() $\rho _g$ and

$\rho _g$ and ![]() $\nu$ are the gas velocity, density and kinematic viscosity, respectively;

$\nu$ are the gas velocity, density and kinematic viscosity, respectively; ![]() $t$ is the time and

$t$ is the time and ![]() $D$ is the diffusion coefficient of

$D$ is the diffusion coefficient of ![]() $\text {CO}_2$;

$\text {CO}_2$; ![]() $\rho$,

$\rho$, ![]() $c_p$ and

$c_p$ and ![]() $\alpha$ are the local density, specific heat capacity at constant pressure and thermal diffusivity, respectively. The heat

$\alpha$ are the local density, specific heat capacity at constant pressure and thermal diffusivity, respectively. The heat ![]() $Q$ can be either the released desublimation heat

$Q$ can be either the released desublimation heat ![]() $Q_d$ or the absorbed sublimation heat

$Q_d$ or the absorbed sublimation heat ![]() $Q_s$.

$Q_s$.

The desublimation and sublimation of ![]() $\text {CO}_2$ take place at the active gas–solid interface

$\text {CO}_2$ take place at the active gas–solid interface ![]() $I_d$ and

$I_d$ and ![]() $I_s$, respectively. Such processes are described by boundary conditions as

$I_s$, respectively. Such processes are described by boundary conditions as

\begin{gather} \left. \begin{gathered} T^{I_{d, s},+} =T^{I_{d, s},-}, \\ \boldsymbol{n} \boldsymbol{\cdot} \left(k \boldsymbol{\nabla} T +\rho c_p \boldsymbol{u} T \right)^{I_{d, s},+} = \boldsymbol{n} \boldsymbol{\cdot} \left(k \boldsymbol{\nabla} T +\rho c_p \boldsymbol{u} T \right) ^{I_{d, s},-} + q. \end{gathered} \right\} \end{gather}

\begin{gather} \left. \begin{gathered} T^{I_{d, s},+} =T^{I_{d, s},-}, \\ \boldsymbol{n} \boldsymbol{\cdot} \left(k \boldsymbol{\nabla} T +\rho c_p \boldsymbol{u} T \right)^{I_{d, s},+} = \boldsymbol{n} \boldsymbol{\cdot} \left(k \boldsymbol{\nabla} T +\rho c_p \boldsymbol{u} T \right) ^{I_{d, s},-} + q. \end{gathered} \right\} \end{gather}

In the above equations, ![]() $\boldsymbol {n}$ is the interface normal pointing to the gas phase,

$\boldsymbol {n}$ is the interface normal pointing to the gas phase, ![]() $+$ and

$+$ and ![]() $-$ denote parameters on either side of

$-$ denote parameters on either side of ![]() $I_{d, s}$,

$I_{d, s}$, ![]() $k=\alpha \rho c_p$ is the thermal conductivity and

$k=\alpha \rho c_p$ is the thermal conductivity and ![]() $q$ is the heat flux caused by

$q$ is the heat flux caused by ![]() $\textrm {CO}_2$ desublimation or sublimation.

$\textrm {CO}_2$ desublimation or sublimation.

In order to model ![]() $\textrm {CO}_2$ desublimation and sublimation using the LB method, the above physical parameters are converted to those in lattice units. For this purpose, dimensionless parameters are derived to act as the conversion criteria between the two systems of units. By introducing the characteristic length

$\textrm {CO}_2$ desublimation and sublimation using the LB method, the above physical parameters are converted to those in lattice units. For this purpose, dimensionless parameters are derived to act as the conversion criteria between the two systems of units. By introducing the characteristic length ![]() $L$, velocity

$L$, velocity ![]() $U$, temperature

$U$, temperature ![]() $T_{ch}$ and density

$T_{ch}$ and density ![]() $\rho _g$, dimensionless parameters marked by asterisks are derived as

$\rho _g$, dimensionless parameters marked by asterisks are derived as

\begin{equation} \left. \begin{gathered}

\boldsymbol{x}^* = \frac{\boldsymbol{u}}{L}, \quad t^* =

\frac{t}{L/U}, \quad \boldsymbol{u}^* =

\frac{\boldsymbol{u}}{U}, \quad \rho^* =

\frac{\rho}{\rho_g}, \quad p^* = \frac{p}{\rho_g U^2},\\

\quad T^* = \frac{T}{T_{ch}}, \quad m_r^* = \frac{m_r}{\rho_gU},\\

h_r^* = \frac{h_r}{c_{p,g}T_{ch}},

\quad k_r^* = k_rU, \quad Re =

\frac{LU}{\nu}, \quad Pe = \frac{LU}{D},\\

\quad Pr = \frac{\nu}{\alpha_g},\quad

\Delta T_s = \frac{T_f-T}{T_{ch}}. \end{gathered}

\right\}

\end{equation}

\begin{equation} \left. \begin{gathered}

\boldsymbol{x}^* = \frac{\boldsymbol{u}}{L}, \quad t^* =

\frac{t}{L/U}, \quad \boldsymbol{u}^* =

\frac{\boldsymbol{u}}{U}, \quad \rho^* =

\frac{\rho}{\rho_g}, \quad p^* = \frac{p}{\rho_g U^2},\\

\quad T^* = \frac{T}{T_{ch}}, \quad m_r^* = \frac{m_r}{\rho_gU},\\

h_r^* = \frac{h_r}{c_{p,g}T_{ch}},

\quad k_r^* = k_rU, \quad Re =

\frac{LU}{\nu}, \quad Pe = \frac{LU}{D},\\

\quad Pr = \frac{\nu}{\alpha_g},\quad

\Delta T_s = \frac{T_f-T}{T_{ch}}. \end{gathered}

\right\}

\end{equation}

The subscript ![]() $g$ refers to physical properties of the flue gas and

$g$ refers to physical properties of the flue gas and ![]() $T_f$ is the freezing temperature of

$T_f$ is the freezing temperature of ![]() $\textrm {CO}_2$. From such a dimensionless derivation, key characteristic numbers are obtained: the Reynolds number

$\textrm {CO}_2$. From such a dimensionless derivation, key characteristic numbers are obtained: the Reynolds number ![]() $Re $, the Péclet number

$Re $, the Péclet number ![]() $Pe $, the Prandtl number

$Pe $, the Prandtl number ![]() $Pr $ and the subcooling degree

$Pr $ and the subcooling degree ![]() $\Delta T_s$. In LB simulations a match of these dimensionless variables ensures the same desublimation and sublimation characteristics between the lattice space and the real physical space.

$\Delta T_s$. In LB simulations a match of these dimensionless variables ensures the same desublimation and sublimation characteristics between the lattice space and the real physical space.

3. Numerical method

The LB method is applied to solve the conservation equations (2.8)–(2.11) in two dimensions. Considering the porous structure of the packed bed, the multiple-relaxation-time (MRT) LB method is employed to avoid the unphysical dependence of permeability on viscosity at the pore scale (Pan, Luo & Miller Reference Pan, Luo and Miller2006). To enforce the boundary conditions in (2.12)–(2.14) for ![]() $\textrm {CO}_2$ desublimation and sublimation, LB boundary schemes are developed. Furthermore, the volume-of-pixel (VOP) method is adopted to treat the evolution of solid

$\textrm {CO}_2$ desublimation and sublimation, LB boundary schemes are developed. Furthermore, the volume-of-pixel (VOP) method is adopted to treat the evolution of solid ![]() $\textrm {CO}_2$ in (2.7) (Kang, Lichtner & Zhang Reference Kang, Lichtner and Zhang2006; Wang et al. Reference Wang, Han, Wang, Ma and Wang2019; Lei & Luo Reference Lei and Luo2021).

$\textrm {CO}_2$ in (2.7) (Kang, Lichtner & Zhang Reference Kang, Lichtner and Zhang2006; Wang et al. Reference Wang, Han, Wang, Ma and Wang2019; Lei & Luo Reference Lei and Luo2021).

3.1. The MRT LB models

Since the flue gas and the solid phases have different thermophysical properties, the energy conservation equation (2.11) is recast as

with the source term ![]() $F_T$ being

$F_T$ being

More details on this derivation can be found in our earlier work (Lei, Wang & Luo Reference Lei, Wang and Luo2021).

To solve the gas flow ((2.8)–(2.9)), species transport (2.10) and heat transfer (3.1), three sets of LB evolution equations are built as follows (Lei & Luo Reference Lei and Luo2019; Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023):

$$\begin{gather}h_i \left( \boldsymbol{x} + \boldsymbol{e}_i \delta _t, t + \delta _t \right) - h_i\left( \boldsymbol{x}, t \right) ={-} \left( {{\boldsymbol{\mathsf{M}}}}^{{-}1} {{\boldsymbol{\mathsf{S}}}}_t {{\boldsymbol{\mathsf{M}}}} \right)_{ij} \left[ h_j \left( \boldsymbol{x},\ t \right) - h_j ^{eq} \left( \boldsymbol{x},\ t \right) \right] \nonumber\\+ \delta _t \bar{F}_{T,i} + \frac{\delta _t^ 2}{2}\frac{\partial \bar{F}_{T,i}}{\partial t}. \end{gather}$$

$$\begin{gather}h_i \left( \boldsymbol{x} + \boldsymbol{e}_i \delta _t, t + \delta _t \right) - h_i\left( \boldsymbol{x}, t \right) ={-} \left( {{\boldsymbol{\mathsf{M}}}}^{{-}1} {{\boldsymbol{\mathsf{S}}}}_t {{\boldsymbol{\mathsf{M}}}} \right)_{ij} \left[ h_j \left( \boldsymbol{x},\ t \right) - h_j ^{eq} \left( \boldsymbol{x},\ t \right) \right] \nonumber\\+ \delta _t \bar{F}_{T,i} + \frac{\delta _t^ 2}{2}\frac{\partial \bar{F}_{T,i}}{\partial t}. \end{gather}$$

Here ![]() $i$ and

$i$ and ![]() $j$ are discrete directions. For fluid moving with the discrete velocity

$j$ are discrete directions. For fluid moving with the discrete velocity ![]() $\boldsymbol {e}_i$ at position

$\boldsymbol {e}_i$ at position ![]() $\boldsymbol {x}$ and time

$\boldsymbol {x}$ and time ![]() $t$,

$t$, ![]() $f_i(\boldsymbol {x}, t)$,

$f_i(\boldsymbol {x}, t)$, ![]() $g_i(\boldsymbol {x},t)$ and

$g_i(\boldsymbol {x},t)$ and ![]() $h_i(\boldsymbol {x},t)$ are their distribution functions of the hydrodynamic,

$h_i(\boldsymbol {x},t)$ are their distribution functions of the hydrodynamic, ![]() $\textrm {CO}_2$ mass fraction and temperature fields, respectively. Here

$\textrm {CO}_2$ mass fraction and temperature fields, respectively. Here ![]() $f_i^{eq}$,

$f_i^{eq}$, ![]() $g_i^{eq}$ and

$g_i^{eq}$ and ![]() $h_i^{eq}$ are the equilibrium distribution functions;

$h_i^{eq}$ are the equilibrium distribution functions; ![]() $\bar {F}_{T,i}$ is the distribution function for the thermal source term

$\bar {F}_{T,i}$ is the distribution function for the thermal source term ![]() $F_T$;

$F_T$; ![]() ${{\boldsymbol{\mathsf{S}}}}$,

${{\boldsymbol{\mathsf{S}}}}$, ![]() ${{\boldsymbol{\mathsf{S}}}}_y$ and

${{\boldsymbol{\mathsf{S}}}}_y$ and ![]() ${{\boldsymbol{\mathsf{S}}}}_t$ are the diagonal relaxation matrices, whereas

${{\boldsymbol{\mathsf{S}}}}_t$ are the diagonal relaxation matrices, whereas ![]() ${{\boldsymbol{\mathsf{M}}}}$ is the transformation matrix to map distribution functions from the physical space to the moment space. The time derivatives in (3.2a–c) (

${{\boldsymbol{\mathsf{M}}}}$ is the transformation matrix to map distribution functions from the physical space to the moment space. The time derivatives in (3.2a–c) (![]() $\partial _t \rho c_p$) and (3.5) (

$\partial _t \rho c_p$) and (3.5) (![]() $\partial _t \bar {F}_{T,i}$) are treated with a backward difference scheme.

$\partial _t \bar {F}_{T,i}$) are treated with a backward difference scheme.

At each time step, after the above evolutions, the macroscopic variables are calculated as

Here, ![]() $\rho _p$ is a variable related to the gas pressure as

$\rho _p$ is a variable related to the gas pressure as ![]() $\rho _p= p / c_s^2$;

$\rho _p= p / c_s^2$; ![]() $c_s = e/ \sqrt {3}$ is the lattice sound speed and

$c_s = e/ \sqrt {3}$ is the lattice sound speed and ![]() $e=\delta _x/\delta _t$ is the lattice speed;

$e=\delta _x/\delta _t$ is the lattice speed; ![]() $\delta _x$ and

$\delta _x$ and ![]() $\delta _t$ denote the lattice spacing and time step, respectively.

$\delta _t$ denote the lattice spacing and time step, respectively.

3.2. The LB boundary scheme for  $\textrm {CO}_2$ desublimation and sublimation

$\textrm {CO}_2$ desublimation and sublimation

For the active gas–solid interface ![]() $I_{d,s}$ with

$I_{d,s}$ with ![]() $\textrm {CO}_2$ desublimation and sublimation, three boundary conditions (i.e. (2.12)–(2.14)) need to be addressed. First, the conjugate heat transfer in (2.14) is automatically realized by solving the energy conservation equation (3.1). Then, the no-slip velocity condition in (2.12) is achieved by the halfway bounce-back scheme. Finally, to implement the species mass conservation condition in (2.13), the

$\textrm {CO}_2$ desublimation and sublimation, three boundary conditions (i.e. (2.12)–(2.14)) need to be addressed. First, the conjugate heat transfer in (2.14) is automatically realized by solving the energy conservation equation (3.1). Then, the no-slip velocity condition in (2.12) is achieved by the halfway bounce-back scheme. Finally, to implement the species mass conservation condition in (2.13), the ![]() $\textrm {CO}_2$ mass fraction gradient at the active interface

$\textrm {CO}_2$ mass fraction gradient at the active interface ![]() $I_{d,s}$ is calculated based on the finite-difference scheme as (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

$I_{d,s}$ is calculated based on the finite-difference scheme as (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

where ![]() $Y^g$ is the

$Y^g$ is the ![]() $\textrm {CO}_2$ mass fraction at the gas grid neighbouring the interface

$\textrm {CO}_2$ mass fraction at the gas grid neighbouring the interface ![]() $I_{d,s}$. By inserting (3.7) into (2.13) and using the ideal gas law, the value of

$I_{d,s}$. By inserting (3.7) into (2.13) and using the ideal gas law, the value of ![]() $Y^{I_{d,s}}$ is calculated as

$Y^{I_{d,s}}$ is calculated as

In this way, the ![]() $\textrm {CO}_2$ mass fractions at the desublimation boundary

$\textrm {CO}_2$ mass fractions at the desublimation boundary ![]() $I_d$ and the sublimation boundary

$I_d$ and the sublimation boundary ![]() $I_s$ are obtained. Therefore, the mass conservation boundary condition in (2.13) can be re-expressed as (3.8)–(3.9), namely, a boundary with a given

$I_s$ are obtained. Therefore, the mass conservation boundary condition in (2.13) can be re-expressed as (3.8)–(3.9), namely, a boundary with a given ![]() $\textrm {CO}_2$ mass fraction

$\textrm {CO}_2$ mass fraction ![]() $Y^{I_{d,s}}$. The halfway bounce-back scheme is used to impose this boundary condition, with the unknown distribution functions at the gas grid

$Y^{I_{d,s}}$. The halfway bounce-back scheme is used to impose this boundary condition, with the unknown distribution functions at the gas grid ![]() $\boldsymbol {x}_g$ adjacent to

$\boldsymbol {x}_g$ adjacent to ![]() $I_{d,s}$ being (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

$I_{d,s}$ being (Zhang et al. Reference Zhang, Shi, Guo, Chai and Lu2012)

Here, the superscript ![]() $'$ denotes the post-collision distribution function,

$'$ denotes the post-collision distribution function, ![]() $\bar {\imath }$ is the opposite direction of

$\bar {\imath }$ is the opposite direction of ![]() $i$ as

$i$ as ![]() $\boldsymbol {e}_i = -\boldsymbol {e}_{\bar {\imath } }$ and

$\boldsymbol {e}_i = -\boldsymbol {e}_{\bar {\imath } }$ and ![]() $\boldsymbol {e}_i$ points to the solid phase zone. More details on the present MRT LB model and boundary treatments are provided in Appendices A and B.

$\boldsymbol {e}_i$ points to the solid phase zone. More details on the present MRT LB model and boundary treatments are provided in Appendices A and B.

3.3. Evolution of solid  $\textrm {CO}_2$

$\textrm {CO}_2$

With the desublimation and sublimation of ![]() $\textrm {CO}_2$, the evolution of a solid

$\textrm {CO}_2$, the evolution of a solid ![]() $\textrm {CO}_2$ structure at the pore scale is tracked by (2.7). In LB simulations this structure evolution is realized by the commonly used VOP method (Kang et al. Reference Kang, Lichtner and Zhang2006; Wang et al. Reference Wang, Han, Wang, Ma and Wang2019). Explicitly, a fine enough mesh is selected to cover the computational domain and each grid node (or pixel) is located at the centre of a control cell with size

$\textrm {CO}_2$ structure at the pore scale is tracked by (2.7). In LB simulations this structure evolution is realized by the commonly used VOP method (Kang et al. Reference Kang, Lichtner and Zhang2006; Wang et al. Reference Wang, Han, Wang, Ma and Wang2019). Explicitly, a fine enough mesh is selected to cover the computational domain and each grid node (or pixel) is located at the centre of a control cell with size ![]() $1\times 1 \times 1$ in lattice units. Each grid is assumed to represent a cell composed of a single material: solid grain cell, solid

$1\times 1 \times 1$ in lattice units. Each grid is assumed to represent a cell composed of a single material: solid grain cell, solid ![]() $\textrm {CO}_2$ cell or flue gas cell. Initially, the volume of solid

$\textrm {CO}_2$ cell or flue gas cell. Initially, the volume of solid ![]() $\textrm {CO}_2$ is set as

$\textrm {CO}_2$ is set as ![]() $V_s=1$ for solid

$V_s=1$ for solid ![]() $\textrm {CO}_2$ grids,

$\textrm {CO}_2$ grids, ![]() $V_s=0$ for gas grids and

$V_s=0$ for gas grids and ![]() $V_s=0$ for packing grain grids, respectively. As the desublimation and sublimation of

$V_s=0$ for packing grain grids, respectively. As the desublimation and sublimation of ![]() $\textrm {CO}_2$ occurs, the value of

$\textrm {CO}_2$ occurs, the value of ![]() $V_s$ is calculated at each time step by

$V_s$ is calculated at each time step by

With the desublimation of ![]() $\textrm {CO}_2$ (i.e.

$\textrm {CO}_2$ (i.e. ![]() $m_r>0$), the value of

$m_r>0$), the value of ![]() $V_s$ increases with time. As

$V_s$ increases with time. As ![]() $V_s$ doubles at a solid

$V_s$ doubles at a solid ![]() $\textrm {CO}_2$ grid (i.e.

$\textrm {CO}_2$ grid (i.e. ![]() $V_s=2$) or increases to

$V_s=2$) or increases to ![]() $V_s=1$ in a grain grid, one of its neighbouring gas grids is converted into a solid

$V_s=1$ in a grain grid, one of its neighbouring gas grids is converted into a solid ![]() $\textrm {CO}_2$ grid. The ratio of the growth probability between the nearest and the diagonal grids is

$\textrm {CO}_2$ grid. The ratio of the growth probability between the nearest and the diagonal grids is ![]() $R_{dp}=1:0.25$, which is consistent with the ratio of weight coefficients

$R_{dp}=1:0.25$, which is consistent with the ratio of weight coefficients ![]() $w_i$ (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023). On the other hand,

$w_i$ (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023). On the other hand, ![]() $V_s$ decreases with the sublimation of

$V_s$ decreases with the sublimation of ![]() $\textrm {CO}_2$ (i.e.

$\textrm {CO}_2$ (i.e. ![]() $m_r<0$). As

$m_r<0$). As ![]() $V_s$ decreases to zero, the solid

$V_s$ decreases to zero, the solid ![]() $\textrm {CO}_2$ grid is turned into a gas grid.

$\textrm {CO}_2$ grid is turned into a gas grid.

3.4. Numerical procedure

The developed MRT LB model for ![]() $\textrm {CO}_2$ desublimation and sublimation was programmed in the C language, following the algorithmic flowchart in figure 3. The main steps are as follows.

$\textrm {CO}_2$ desublimation and sublimation was programmed in the C language, following the algorithmic flowchart in figure 3. The main steps are as follows.

(i) Start the process and initialize the gas flow, temperature and

$\textrm {CO}_2$ mass fraction fields.

$\textrm {CO}_2$ mass fraction fields.(ii) Solve the flow field to update the gas velocity

$\boldsymbol {u}$.

$\boldsymbol {u}$.(iii) Simulate the heat and

$\textrm {CO}_2$ transfer to obtain temperature

$\textrm {CO}_2$ transfer to obtain temperature  $T$ and

$T$ and  $\textrm {CO}_2$ mass fraction

$\textrm {CO}_2$ mass fraction  $Y$.

$Y$.(iv) Calculate the mass transfer rate

$m_r$ and classify three gas–solid boundaries as

$m_r$ and classify three gas–solid boundaries as  $I_n$,

$I_n$,  $I_d$ and

$I_d$ and  $I_s$.

$I_s$.(v) Implement

$\textrm {CO}_2$ desublimation and sublimation at boundaries

$\textrm {CO}_2$ desublimation and sublimation at boundaries  $I_d$ and

$I_d$ and  $I_s$, leading to changes in gaseous

$I_s$, leading to changes in gaseous  $\textrm {CO}_2$ mass fraction

$\textrm {CO}_2$ mass fraction  $Y^{I_{d,s}}$, solid

$Y^{I_{d,s}}$, solid  $\textrm {CO}_2$ volume

$\textrm {CO}_2$ volume  $V_s$ and heat terms

$V_s$ and heat terms  $Q_{d,s}$.

$Q_{d,s}$.(vi) Track evolutions of solid

$\textrm {CO}_2$ structure, bringing about changes in flow channels and thermophysical properties of updated grids.

$\textrm {CO}_2$ structure, bringing about changes in flow channels and thermophysical properties of updated grids.(vii) Enforce boundary conditions at both external and internal boundaries.

(viii) Repeat (ii)–(vii) until the stop criterion is satisfied.

Figure 3. The schematic diagram of the overall numerical implementation.

To enable parallel execution, the message passing interface library is utilized and the developed LB code is validated comprehensively. Appendix C is provided to elucidate model validation tests. Upon the validation of the developed LB code, pore-scale simulations are conducted to investigate ![]() $\textrm {CO}_2$ desublimation and sublimation on a single packing grain and in a packed bed, employing 640 and 1280 compute cores for the simulations of each configuration, respectively. In contrast to our prior investigation of

$\textrm {CO}_2$ desublimation and sublimation on a single packing grain and in a packed bed, employing 640 and 1280 compute cores for the simulations of each configuration, respectively. In contrast to our prior investigation of ![]() $\textrm {CO}_2$ desublimation on an isothermal grain (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023), the current study expands the scope to encompass both desublimation and sublimation of

$\textrm {CO}_2$ desublimation on an isothermal grain (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023), the current study expands the scope to encompass both desublimation and sublimation of ![]() $\textrm {CO}_2$ within the context of CCC. The mathematical frameworks built here are augmented by incorporating new phase change processes ((2.1)–(2.2)) and modified mass transfer rates (2.3). These enhancements facilitate a comprehensive treatment of the multiphysics behind CCC, including the released desublimation heat

$\textrm {CO}_2$ within the context of CCC. The mathematical frameworks built here are augmented by incorporating new phase change processes ((2.1)–(2.2)) and modified mass transfer rates (2.3). These enhancements facilitate a comprehensive treatment of the multiphysics behind CCC, including the released desublimation heat ![]() $Q_d$ and the absorbed sublimation heat

$Q_d$ and the absorbed sublimation heat ![]() $Q_s$, the dynamic boundaries pertinent to

$Q_s$, the dynamic boundaries pertinent to ![]() $\textrm {CO}_2$ desublimation

$\textrm {CO}_2$ desublimation ![]() $I_d$ and sublimation

$I_d$ and sublimation ![]() $I_s$, and the generation and consumption of solid

$I_s$, and the generation and consumption of solid ![]() $\textrm {CO}_2$. Consequently, the boundary schemes and the evolution of solid

$\textrm {CO}_2$. Consequently, the boundary schemes and the evolution of solid ![]() $\textrm {CO}_2$ in the present LB model allow for a more detailed physical description of the phenomena compared with those in our previous research (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023).

$\textrm {CO}_2$ in the present LB model allow for a more detailed physical description of the phenomena compared with those in our previous research (Lei et al. Reference Lei, Luo, Hernández Pérez, Wang, Wang, Restrepo Cano and Im2023).

4. Results and discussion

For the cryogenic packed bed in figure 2, key geometrical parameters are set as: length ![]() $l_x=124.8\, \textrm {mm}$, width

$l_x=124.8\, \textrm {mm}$, width ![]() $l_y=20.8\, \textrm {mm}$, grain diameter

$l_y=20.8\, \textrm {mm}$, grain diameter ![]() $l_d=10.0\, \textrm {mm}$ and porosity

$l_d=10.0\, \textrm {mm}$ and porosity ![]() $\psi =0.64$. From such a bed, a small-size domain encompassing a single grain is selected for single-grain simulations. The void volume fraction of this small-size domain equals the bed porosity

$\psi =0.64$. From such a bed, a small-size domain encompassing a single grain is selected for single-grain simulations. The void volume fraction of this small-size domain equals the bed porosity ![]() $\psi$ and the other geometrical parameters are

$\psi$ and the other geometrical parameters are ![]() $l_{sx}=14.7\, \textrm {mm}$ and

$l_{sx}=14.7\, \textrm {mm}$ and ![]() $l_{sy}=14.7\, \textrm {mm}$. Initially, packing grains are cooled to

$l_{sy}=14.7\, \textrm {mm}$. Initially, packing grains are cooled to ![]() $T_w$ for

$T_w$ for ![]() $\textrm {CO}_2$ desublimation and flow paths among grains are filled with

$\textrm {CO}_2$ desublimation and flow paths among grains are filled with ![]() $\textrm {N}_2$ at temperature

$\textrm {N}_2$ at temperature ![]() $T_w$. The incompressible flue gas at the initial condition

$T_w$. The incompressible flue gas at the initial condition ![]() $(T_0, Y_0, u_0, p_0 )$ is fed in from the left inlet (

$(T_0, Y_0, u_0, p_0 )$ is fed in from the left inlet (![]() $x=0$) and the component

$x=0$) and the component ![]() $\textrm {CO}_2$ is desublimated on packing grains. The four external boundaries of the computational domain are set as follows: the flue gas at

$\textrm {CO}_2$ is desublimated on packing grains. The four external boundaries of the computational domain are set as follows: the flue gas at ![]() $(T_0, Y_0, u_0, p_0 )$ is fed in from the inlet, a fully developed flow is considered at the outlet, the periodic conditions are imposed at the bottom and top. More details of these boundaries are provided in Appendix B.

$(T_0, Y_0, u_0, p_0 )$ is fed in from the inlet, a fully developed flow is considered at the outlet, the periodic conditions are imposed at the bottom and top. More details of these boundaries are provided in Appendix B.

The desublimation parameters and thermophysical properties used in the following simulations are listed in table 1. These physical parameters are converted into lattice units by matching the dimensionless parameters in (2.15), where characteristic parameters are selected as

Prior studies have noted the importance of the gas feed rate and initial bed temperature to the carbon capture performance of CCC. Therefore, ![]() $u_0$ and

$u_0$ and ![]() $T_w$ are varied to change the operating conditions, covering

$T_w$ are varied to change the operating conditions, covering ![]() $u_0$ from

$u_0$ from ![]() $1.22\times 10^{-3}\, \textrm {m}\,\textrm {s}^{-1}$ to

$1.22\times 10^{-3}\, \textrm {m}\,\textrm {s}^{-1}$ to ![]() $6.10\times 10^{-2}\, \textrm {m}\,\textrm {s}^{-1}$ and

$6.10\times 10^{-2}\, \textrm {m}\,\textrm {s}^{-1}$ and ![]() $T_w$ from

$T_w$ from ![]() $80\, \textrm {K}$ to

$80\, \textrm {K}$ to ![]() $180\, \textrm {K}$. These two parameters are characterized by the Péclet number

$180\, \textrm {K}$. These two parameters are characterized by the Péclet number ![]() ${{Pe}}$ and the subcooling degree of bed

${{Pe}}$ and the subcooling degree of bed ![]() $\Delta T_s=(T_f-T_w)/T_0$, which lie in ranges of

$\Delta T_s=(T_f-T_w)/T_0$, which lie in ranges of ![]() $[1.55, 77.84]$ and

$[1.55, 77.84]$ and ![]() $[0.049, 0.389]$, respectively. Values of these two parameters are listed in table 2 in Appendix D.

$[0.049, 0.389]$, respectively. Values of these two parameters are listed in table 2 in Appendix D.

Table 1. Physical properties for simulations of ![]() $\textrm {CO}_2$ desublimation and sublimation during CCC.

$\textrm {CO}_2$ desublimation and sublimation during CCC.

Table 2. Values of the initial bed temperature ![]() $T_w\ ({\textrm {K}})$, gas feed rate

$T_w\ ({\textrm {K}})$, gas feed rate ![]() $u_0(\times 10^{-2} \, \textrm {m}\,\textrm {s}^{-1})$ and grain position

$u_0(\times 10^{-2} \, \textrm {m}\,\textrm {s}^{-1})$ and grain position ![]() $r_x\ (\textrm {m})$ (with

$r_x\ (\textrm {m})$ (with ![]() $r_y = l_y$), as well as the corresponding subcooling degree

$r_y = l_y$), as well as the corresponding subcooling degree ![]() $\Delta T_s$, Péclet number

$\Delta T_s$, Péclet number ![]() $Pe $ and bed porosity

$Pe $ and bed porosity ![]() $\psi$.

$\psi$.

To ensure the numerical solution is grid independent, grid convergence tests were carried out first. Two meshes of size ![]() $5400 \times 900$ and

$5400 \times 900$ and ![]() $640 \times 640$, with a lattice resolution