Article contents

Liquid-state pyroelectric energy harvesting

Published online by Cambridge University Press: 19 November 2020

Abstract

A liquid-state pyroelectric energy harvester is described and a remarkable capacity to convert a thermal gradient into electrical energy is demonstrated.

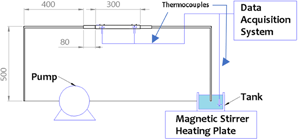

Increasing the sustainability of energy generation can be pursued by harvesting extremely low enthalpy sources: low temperature differences between cold and hot reservoirs are easily achieved in every industrial process, both at large and small scales, in plants as well as in small appliances, vehicles, natural environments, and human bodies. This paper presents the assessment and efficiency estimate of a liquid-state pyroelectric energy harvester, based on a colloid containing barium titanate nanoparticles and ferrofluid as a stabilizer. The liquid is set in motion by an external pump to control velocity, in a range similar to the one achieved by Rayleigh–Bénard convection, and the colloid reservoir is heated. The colloid is injected into a Fluorinated Ethylene Propylene pipe where titanium electrodes are placed to collect electrical charges generated by pyroelectricity on the surface of the nanoparticles, reaching 22.4% of the ideal Carnot efficiency of a thermal machine working on the same temperature drop. The maximum extracted electrical power per unit of volume is above 7 mW/m3 with a ΔT between electrodes of 3.9 K.

Keywords

- Type

- Original Research

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 10

- Cited by