INTRODUCTION

A successful excavation campaign in 2012, as part of the Montelabate Project carried out by the Universities of Cambridge and Queen's Belfast,Footnote 1 led to the discovery of four Roman kilns near the abbey of Montelabate (Perugia, Umbria, Italy). This discovery offers important new insights into the economic history of the area and the production and circulation of goods in Regio VI (Umbria). This article discusses the development of this production site, which revealed a long continuity of ceramic manufacturing starting in the mid-imperial period, when it mostly produced amphorae, and continuing into late antiquity with the production of tiles and coarseware, indicating a degree of stability in the rural economic system. Other important aspects to be considered in the study of pottery manufacturing are the need for a location near clay sources and water, and the existence of facilities for forming, drying, firing and storing the products. Moreover, even in the study of the kilns some open questions and limitations remain, such as the sequence of use of the structures and their precise chronology since only the underground parts, the firing chambers, are preserved and were filled and abandoned in antiquity. The article will focus mainly on the manufacturing of amphorae and their economic system of production, although a brief discussion of the late antique products and imports is crucial for defining the ceramic tradition of the site.Footnote 2

THE SITE

The site of Montelabate is located 30 km northeast of Perugia, in a valley characterized by a series of gentle hills 250–300 m above sea level. The valley is overlooked by the Benedictine abbey of S. Maria di Valdipone, now owned by the Gaslini Foundation, in an area known for pottery production until the early twentieth century (Figs 1 and 14).

Fig. 1. Map of the site location and other major sites mentioned in the text (base map courtesy of David Redhouse).

In geological terms, the valley is in the plain of the Umbrian Basin delimited by lower hills to the east separating it from the Gubbio valley, which is composed of Mesozoic–Tertiary and marly limestone (Malone and Stoddart, Reference Malone and Stoddart1994: 17). Ancient and modern pottery manufacturing in the valley used the Plio-Pleistocene clay deposits from the ancient Tiber basin, as the area is characterized by a series of lithostratigraphic units alternating alluvial sandy-clay layers, created by the watercourses running into the lake that later becomes the river Tiber, interbedded with calcareous and travertine gravels.Footnote 3 The territory of Montelabate comprises the catchment area of a series of small rivers and streams running southwest and flowing into the Tiber.

An initial field walking survey conducted in 2010 as part of the Montelabate Project (Stoddart et al., Reference Stoddart, Baroni, Ceccarelli, Cifani, Clackson, Ferrara, della Giovampaola, Fulminante, Licence, Malone, Mattacchioni, Mullen, Nomi, Pettinelli, Redhouse and Whitehead2012) revealed the presence of a production area on the top of a hill at 340 m above sea level, located within walking distance of a rich clay depositFootnote 4 and a series of streams at the foot of the hill (Fig. 14, site 6, further below). River connectivity provided by the Ventia, a tributary of the Tiber 5 km away, and the densely forested hills surrounding the site (Umbria was rich in forests as attested by Cicero, De divinatione 1.94) were an ideal combination for the exploitation of local resources for production.Footnote 5 The survey also revealed an interesting spatial patterning in the valley in the Roman period: small rural settlements and farms filled the area, distributed on the lower sandstone foothills between 250 and 300 m above sea level, on the Pliocene lacustrine sediments and on the terraces of the Tiber tributaries. Interestingly, no traces of a villa were identified. Evidence for agricultural exploitation and the production of wine in the valley is provided by a substantial number of amphora fragments of the types discovered at Montelabate that were recorded during the field walking survey.

THE MONTELABATE WORKSHOP

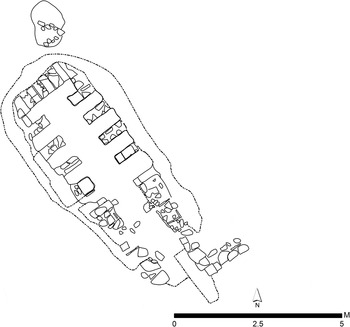

The five-week excavation season in 2012, directed by the author, concentrated on an area measuring 25 m by 30 m on the summit of the small hill (Fig. 2). The distribution of the surface materials combined with a geophysical surveyFootnote 6 indicated six defined areas for excavation which subsequently revealed three kilns, three dumps of material and a separate structure, possibly a drying shed. Two of the kilns, in use for the longest period, were located on the summit of the hill and oriented north–south, probably to create an updraft favourable to the firing process (Fig. 2, kilns 1 and 2). A third kiln was located further down the hill (Fig. 2, kiln 3) with the same orientation but an elongated combustion chamber, probably to increase the forced draught. The kilns were all rectangular, with a double updraft chamber (the Cuomo di Caprio II/b typology (Cuomo di Caprio, Reference Cuomo di Caprio2007: 523–5, fig. 169)).

Fig. 2. Plan of the workshop (drawing: author).

Only the underground part of the excavated kilns was preserved, due to the shallow overburden (approximately 30–40 cm) and their past exposure to regular ploughing. The combustion chamber consisted of refractory brick walls and arches supporting the perforated floor that separated it from the firing chamber. The stocking-hole (or praefurnium) of each kiln is preserved: it was constructed using low brick walls covered by a brick arch that led to the combustion chamber where the fuel was placed. Outside the kilns were several associated work surfaces made of flat limestone blocks. No traces of the upper parts covering the firing chamber were identified: these were temporary in nature and served only for a single firing process. It is evident that at Montelabate the kilns were gradually abandoned and deliberately filled, and that the standing walls were later reused for open firing.

THE KILNS

Kiln 1 was the best-preserved structure and consisted of a lower combustion chamber 3.25 m wide, 3.10 m long and 1.28 m deep with a short praefurnium (Figs 2 and 3). The chamber is composed of a perimeter wall built using broken tiles with the raised lateral edge used for the facing, bonded with mortar and heavily fired due to the heat. The rear wall of the combustion chamber was later reinforced by a refractory brick wall 0.16 m wide, suggesting that the structure became very fragile as a result of continuous exposure to high temperatures, evidence of the prolonged use of the kiln.

Fig. 3. Plan and sections of kiln 1 (drawing: author).

Immediately beneath the plough soil, which had been heavily disturbed up to a depth of 0.35 m, the combustion chamber was filled with a layer of reddened soil 0.20 m deep, together with numerous bricks belonging to the structure and a few fragments of amphorae. Immediately below this was a layer with no inclusions. At a depth of 1.20 m a thick layer of ash containing charcoal residue from the last firing was discovered and below it the floor made of mortar mixed with clay. Several tiles and a few fragments of potteryFootnote 7 were discovered in the fill of this last layer within the combustion chamber, providing further evidence of the prolonged use of the kiln and the deliberate filling of the structure. Inside the combustion chamber, half-sectioned for the purposes of excavation, seven rectangular pillars were recorded that supported the arches upon which the perforated floor of the firing chamber was built (Fig. 3). The walls, 0.20 m wide and 0.90 m long, were built of brick and separated by a slightly inclined tiled floor. The praefurnium walls, oriented towards the southeast, 0.65 m wide and 1.20 m deep, were built with the same construction technique as the side walls of the rest of the structure. The joining section of the brick arch was collapsed inside the flue or fire tunnel. It is difficult to determine the kiln's capacity: the estimated area of the firing chamber floor is around 10 m2 but its volume was determined by the structure covering the chamber. Structures of this type, frequently attested in central Italy, are generally assumed to have produced tiles and bricks.Footnote 8 Close to the kiln many overfired tiles were recorded, but nor should the production of amphorae and coarseware be ruled out, as many fragments were also discovered on the floor of the combustion chamber.

Alongside the kiln the excavation identified several structures with a stone facing, built abutting the eastern wall of the praefurnium with an identical length and bonded perpendicularly to a wall built of squared stones 0.40 m high and 1.50 m long (Fig. 4). This was a work surface, probably to place vases upon before firing or on which to store fuel for the long process of firing.

Fig. 4. Photo of kiln 1 and the structures with an external stone facing (photo: author).

Located to the southwest and parallel to kiln 1 at a distance of 10 m, a second production area was identified composed of two kilns (Fig. 5). The older kiln (labelled 2a) has a square plan 2.50 m in width and 2.80 m in length. The foundation walls of the firing chamber, better preserved than in kiln 1, are 0.35 m wide, suggesting that this kiln had a smaller capacity. The north wall and the east-northeast corner of the combustion chamber were made of broken tiles with the raised lateral edge used for the facing. A single context was excavated within the fill of the firing chamber, which was not fully excavated. The traces of six collapsed brick arches were visible whilst the praefurnium, which has an estimated length of 1.10 m, was destroyed by the construction of kiln 2b, of identical orientation. The perforated floor of the firing chamber had an estimated surface area of 9 m2.

Fig. 5. Plan of kilns 2a and 2b (drawing: author).

Kiln 2b was built partially inside the combustion chamber of the earlier kiln 2a, reusing the material from its walls (Figs 2 and 5). The structure has an elongated rectangular combustion chamber measuring 1.25 m by 4 m whose inner face was lined with a thick layer of overfired clay, varying in thickness between 2.5 and 3 cm. The floor was a compact surface made of overfired clay mixed with mortar. There were no traces of arches to support the perforated floor of the firing chamber which instead may have rested on the side walls of the combustion chamber which were built with limestone blocks mixed with broken tiles and mortar. In its last phase of use, the praefurnium was extended by 1.60 m to fill the entire width of the kiln and enclosed by two parallel walls built using square blocks of the local limestone. The structure opened to the southeast, and two layers of ash and charcoal were discovered in front of the kiln, evidence of the repeated clearance of the firing chamber, which was also filled with fragments of overfired pottery, the majority of which were amphorae alongside some coarseware. However, their presence in the ash layers could not be associated directly with the final use of the kiln, as numerous production wasters were scattered across the entire manufacturing area. The need to expand the praefurnium so that the fuel would burn ensured that the pottery being fired would not come into direct contact with the gases and ash. It is possible that the kiln did not have a combustion chamber and that it was abandoned following an attempt to fire tiles which failed due to an uncontrolled fire, evidenced by the fusion of the products and the subsequent collapse of the structure. This suggests that the firing technology may have been in decline during the later use of the manufacturing area. A parallel for this type of kiln has been excavated at Colleferro,Footnote 9 although in this example the chronology of production cannot be determined with certainty. Evidence that the area was reused is provided by the construction of several drystone walls running parallel and perpendicular to the orientation of the kilns as well as numerous traces of open firing.

On the west side of the kiln, at the level of the structure's foundations, the excavation identified evident traces of burning in an area 1.5 m long and approximately 0.80 m wide, interpreted as evidence of an open temporary pit kiln (Cuomo di Caprio, Reference Cuomo di Caprio2007: 506–7). This method of producing pottery was only suitable for vessels able to withstand the thermal shock of firing through direct contact with the fire, in a heavily reduced atmosphere; it often produced poor results, and the vessels were either overcooked or deformed. At Scoppieto a similar open fire pit used to make ceramics in the second–third century AD was identified, although a raised brick floor was used rather than placing the material directly on the ground (Nicoletta, Reference Nicoletta2010: 263ff.). Unfortunately, due to the minimal amount of topsoil (approximately 0.30 m), it was difficult to determine with any accuracy what was produced at Montelabate, although temporary pit kilns of this type are usually only associated with the small-scale production of coarseware, at a time when the main kilns had already been destroyed and abandoned. These traces testify to continued production at this site, the wasters of which, discussed below, indicate a date up to the fifth century AD.

Kiln 3 was located on the southern part of the hill, at a level 1.02 m below kilns 1 and 2a–b. It consisted of an elongated rectangular combustion chamber, 6.15 m long and 2.30 m wide (Figs 2 and 6). The kiln, orientated northeast to southwest, had a praefurnium opening to the southeast, and had also been disturbed by ploughing, with a topsoil depth of approximately 0.45 m.

Fig. 6. Plan of kiln 3 (drawing: author).

Inside, the combustion chamber, dug into the clay bed to a depth of 0.80 m, was reinforced on the sides by walls built in brick and stones and with eight interspaced supporting walls on each side supporting the perforated floor above. The walls, preserved to a height of 0.40 m and a length of 0.35 m, were built using refractory bricks vitrified by their exposure to high temperatures. The fill of the structure contained numerous fragments of overfired pottery including amphorae, coarseware and thin-walled ware, of which no wasters were found. At the back of the combustion chamber (Fig. 7), three small walls (0.50 m long and 0.27 m wide) built using broken tiles and bonded with mortar created four openings of 0.15 m width, all lined with tiles and gently sloping upwards, indicating that a forced draft was employed in firing.Footnote 10 There were probably further air vents along the longer sides of the combustion chamber, given its considerable length: the estimated size of the firing chamber floor is over 14 m2.

Fig. 7. Kiln 3. Detail of the back of the combustion chamber. (Photo: author.)

The original praefurnium of the kiln was 1.20 m long; it was covered by an arch built in refractory bricks bound by heavily fired mortar. It was subsequently extended by a metre, using broken tiles with the raised lateral edge used for the facing. The north side of the later praefurnium was a wall of 1.33 m length, built using small limestone blocks upon which rested a further perpendicular wall. The latter may have served as a retaining wall for the structure towards the top of the hill and as a work surface. Inside the praefurnium was a collapse of stones and bricks, which covered a layer of ash.

It is interesting to note that the significant length of the praefurnium, over 2 m, allowed the fuel to burn inside it, preventing the combustion gases and ash from damaging the material, and that the air vents allowed for firing in a mainly oxidizing atmosphere.Footnote 11 The plan of the kiln presents similarities with the substantial amphorae production facilities in Tuscany in the Ager PisanusFootnote 12 and with the four adjacent kilns at Albinia,Footnote 13 each of which had an estimated capacity between 250 and 600 amphorae in a single firing (Vitali, Reference Vitali2007: 44).

Given its production capacity, hypothetically over 1,000 amphorae per month, it is reasonable to assume that kiln 3 was the most important on site for the manufacture of amphorae and coarseware in the mid-Imperial period and that it was used in conjunction with kilns with a smaller capacity, as suggested by the distribution of the pottery dumps (see below). In a later phase the smaller structures were used for the production of coarseware and bricks, similarly to the kilns at Albinia (Vitali, Reference Vitali2007: 39–42).

The discovery of such a large production facility at Montelabate is significant, as previously only isolated structures associated with the production of amphorae and coarseware have been discovered in Umbria: a kiln with a rectangular double updraft chamber and a central corridor was excavated at Ponticello near Valfabbrica, approximately 10 km south of Montelabate, near the river Chiascio where brick production has been identified (Massiria, Reference Massiria1982–3: 369; Manconi, Reference Manconi and Bojani1998: 85). At Gubbio, in Viale delle Vittorina, two circular kilns of the Cuomo di Caprio I/d type producing thin-walled ware and coarseware have been excavated, each with a central corridor and a raised firing platform supported by small arches (Cipollone, Reference Cipollone1984–5: 100). In 1979 at Spello, in the Portonaccio area (in Via Baldini), a kiln was identified in a section whilst a clay soaking pit was excavated; they were probably associated with a nearby villa (Cipollone, Reference Cipollone1983: 134). In 1971 at Foligno, in the Monte Franca area, a square kiln was excavated that was probably used for the production of tiles and coarseware (Bonomi Ponzi, Reference Bonomi Ponzi1983: 160). A squared double chamber updraft kiln with an internal wall dividing the combustion chamber into two parts (a II/c Cuomo di Caprio type kiln, measuring 3 m by 4.3 m) has been excavated at Nocera Umbra (Brizio, Reference Brizio1891: 313; Manconi, Reference Manconi and Bojani1998: 86) although the production is unknown. A final example, excavated in 2009 in Perugia (Via del Bovaro), had a squared double chamber updraft with an internal wall dividing the combustion chamber into two parts (II/c Cuomo di Caprio type) which was used to produce bricks and probably dated to the Roman period, although this site is also unpublished.Footnote 14

THE MANUFACTURING PROCESS

The manufacturing process required clay to be hydrated to create the paste to form a vessel.Footnote 15 At Montelabate, so far traces of clay soaking have been identified in the form of a shallow oval pit cut into the compact clay soil north of kiln 3 (Fig. 6), 1.45 m in length, 1.05 m in width and 0.50 m in depth, faced with small squared limestone blocks.

Southwest of the kilns at a distance of 6 m from kilns 2a and 2b, and equidistant from kiln 3, we discovered a further structure. The existing remains consist of the foundations of two parallel walls and a perpendicular wall built using square limestone blocks and bricks bound with mortar which defined an area composed of two rooms with beaten earth floor surfaces (Fig. 2). The southern foundation is preserved for a length of 5.05 m whilst the northern foundation is preserved for a length of 4.65 m. This area was covered with a tiled roof and, despite there being no traces of the wheel, the structure was most probably used to form, dry and store the vessels before firing: the length of time needed for an object to dry varied depending on its thickness and the time of year.Footnote 16 This building, the only one identified on site, may also have served to store fuel, as wood required a lengthy drying process to become suitable for firing: the presence of water in the fuel may cause the pottery to break during firing. This procedure, which varied depending on the type of wood used, could have required up to two years, as was the case for potters at Vasanallo in Lazio even in the early twentieth century (Peña, Reference Peña1992: 102). In the southwestern corner of the building was a rectangular dump of misfired pottery.

POTTERY DUMPS

The firing process for the ceramics produced at Montelabate involved only one stage: a single firing, initially at a low temperature to remove residual water, then at a higher temperature reaching about 800° after which the kiln would be left to cool down.Footnote 17 By comparison with procedures at Vasanello in modern times (Peña, Reference Peña1992: 102), this operation could last seven days, with the proportion of failed products at around 10–20%; we can assume that the lesser control over fire and fuel in the Roman period led to a higher percentage of loss in the ceramics. This is confirmed by the ubiquitous presence of wasters over the entire hill, brought to the surface by mechanical ploughing. Following the removal of the ploughed topsoil (approximately 0.45 m deep), an elliptical pottery waste pit measuring 2.5 m by 5 m, and 0.85 m deep, was identified in trench 4 (Fig. 2, trench 4; Fig. 8). A higher concentration of amphorae was identified in the western part of the trench, whilst in the eastern section there was an accumulation of tiles mixed with ash and compact clay. After removing the first layer we observed a further three phases of amphora and brick dumping: two layers that could be differentiated by a considerable amount of ash, and the layer below characterized by the presence of hard compacted clay.

Fig. 8. Pottery dump in trench 4 (photo: author).

In the building in trench 5, approximately 0.60 m below ground level, a sub-rectangular waste pit measuring 3.5 m by 4 m was uncovered, consisting of amphora wasters, coarseware and mortaria (Fig. 2, trench 5) that had partially destroyed the workshop floor surface. This dump, unlike the others that mainly contained amphorae, yielded different production waste testifying to the later ceramic production phases.Footnote 18

Finally, a small test trench measuring 1 m by 1 m (Fig. 2, trench 6) was excavated along the road running parallel to the hill with the kilns, where a large concentration of material was visible on the surface. Following the removal of the plough soil, a single layer 0.95 m deep was identified, consisting entirely of extremely fragmented and compacted amphora sherds belonging to a dump.

PRODUCTION TOOLS

The excavation recovered several tools belonging to the production process of the workshop including supports and separating rings. The majority of these items were discovered in the upper layer and therefore cannot be associated with an individual kiln. The supports, used to avoid direct contact between the vessel and the kiln floor, were recovered from the topsoil (four fragments), from the dump in trench 4 (one fragment) and a fragment from the upper fill of kiln 2a (Fig. 9.1), all of which were overfired. These instruments have a cylindrical shape with a flat resting base and were made with a rough clay mixture. The limited number found is due to the fact that they could only be used a few times and were not preserved. Their diameter, ranging from 10 to 13 cm, indicates that they were probably functional also for forming amphorae: similar types have been discovered in dumps at Spello (Lapadula, Reference Lapadula1997: fig. 23) and at Scoppieto (Bergamini, Reference Bergamini2008a: 332, no. 623, Group II).

Fig. 9. Production tools (drawing: author).

Only three fragments of separating rings, used for ceramics and probably for open forms, were recovered on the surface (Fig. 9.2). They are shaped as a disc with an oval cross-section, and the only recognizable fragment has a diameter of 8 cm. Another item probably used as a spacer was a spool found in dump 5 (Fig. 9.3).

THE PRODUCTION

The Montelabate workshop offers new and important insights for the analysis of ceramic production, particularly that of flat-bottomed amphorae in Regio VI. Sources link these to the production of the hirtiola grape variety, well known in Maevania and in the Todi area (Pliny, Natural History 14.36–7),Footnote 19 but also widespread in Umbria; given the large number of vessels found, its preferential markets appear to have been Rome and Ostia.

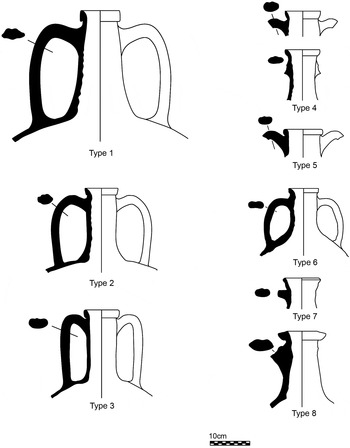

The substantial number of failed amphorae discovered at Montelabate reveal that we are dealing with a large-scale production with little standardization, as eight different types (types 1–8) were identified. They also provide evidence of the varying technical expertise in ceramic manufacturing, stimulated by the trade in agricultural products: on site there are different concentrations of failed products, which will be discussed in detail.

The availability of clay at the site had the great advantage of speeding up the production process. Most of the amphorae have the same reddish-yellow fabric (Munsell 5YR 6/8) when underfired, and light reddish brown (Munsell 5YR 6/4) when correctly fired.Footnote 20 Generally, the surface and breaks have the same colour due to being fired in an oxidizing atmosphere, and the occasional grey core suggests that the oxidizing process did not reach completion, possibly due to the way amphorae were stacked in the kiln. Several examples have a hard grey vitrified surface (Munsell 2.5Y5/2) due to the intensity of the heat from the firing of the kiln, suggesting that they were directly exposed to the heat source.

The fragmentary nature of the materials prevents an evaluation of the full height of the vessels, but the frequent pattern of breakage at the neck and at the handles suggests the forming process: first the body would have been made and left to dry, then the neck and the rim would have been thrown with the addition of clay, and finally the handles were applied.Footnote 21 This weakening at the join of the handles and their breakage also indicates that the clay may have had a high shrinkage and that the application of different parts (neck and rim, handles) required a partially dry body.Footnote 22 The rim diameters vary between 7.5 and 9 cm, neck heights between 9 and 18 cm and base diameters between 5 and 7.5 cm, revealing differences in size. A study of various complete samples by Lapadula (Reference Lapadula1997: 138–44) suggests that the amphorae produced at Montelabate had an average estimated capacity of 29 sextarii (16 L), while a few samples had a larger capacity of 34–5 sextarii (18–19 L). The smaller size with thinner walls may have required a protective layer of straw during transportation.

All of the amphorae used in the present study were discarded products: they were not suitable for the wine trade, as they were either overfired, underfired or fractured.Footnote 23 The overfiring of clay objects was caused by excessively high temperatures or too long a period of firing resulting in a ‘vitrification’ of the surfaces. By contrast, underfiring produced a failed sintering, resulting in a soft porous surface, as was the case for most of the fragments discovered in the pottery dump in trench 4. Finally, another type of failed product consisted of fractured ceramic vessels unable to withstand the thermal shock of cooling, especially at the handles which were probably formed when the vessel was too dry.

In general, the small size of this wine container, with an estimated capacity of 13 to 19/20 L according to Lapadula (Reference Lapadula1997: 135), and its flat-bottomed shape were ideal for medium-range overland and particularly river transport (Panella Reference Panella1989: 159–60). Moreover, its morphology met the short-term needs of wine consumption without the need for decanting; these amphorae were thus the product's final container: they are probably the lagonae mentioned by Juvenal (7.121).Footnote 24 This type of flat-bottomed amphora does not seem to have a univocal definition but varies according to geographical region; Lapadula's (Reference Lapadula1997) classification currently remains the only attempt at a systematic approach to these types of amphorae, originally defined as ‘Spello’ type after the name of the site where its production was first identified (Manconi, Reference Manconi1989: 590–1). In the context of Ostia, they are classified as Ostia III, 369–70 / II, 521 (Panella, Reference Panella1989: 143–6; Rizzo, Reference Rizzo, Rizzo and Panella2014: 130), while the specimens from the Upper Tiber valley have been called ‘Tiberine’ and ‘Altotiberine’Footnote 25 as it was precisely along the Tiber that the amphorae's wine cargo reached the markets of Rome and Ostia (Arthur, Reference Arthur, Potter and King1997: 314).Footnote 26

These amphorae were generally produced from the Tiberian–Claudian period to the end of the second century AD and perhaps also in the early third century AD, when they probably faced competition from the increasing use of wooden barrels, as epigraphic evidence seems to indicate (Panella, Reference Panella1989: 162–3).Footnote 27 In Rome, these wine amphorae are the most frequently attested Italic type after the Dressel 2–4 in archaeological contexts starting from the Flavian period and throughout the second century AD (Arthur, Reference Arthur, Potter and King1997: 314–15, table 59; Lapadula, Reference Lapadula1997: 128; Rizzo, Reference Rizzo, Rizzo and Panella2014: 130). In an excavation in Via Sacchi on the Janiculum, amphorae of type III, 369–370/II, 521 increase in proportion to reach the highest percentage in the late Antonine layers (101 examples, representing over 5% of the entire context (Ferrandes, Reference Ferrandes and Filippi2008: 261), whilst in an excavation on Via Marmorata they account for 11% of the total in the Antonine layers (Bertoldi, Reference Bertoldi, Capodiferro and Quaranta2011: 148, almost identical in numbers to the Dressel 2–4). In the Rome area during the second century AD these amphorae are the most common type of wine containers: fragments have been found as far away as the coastal sites of Lazio, such as Ardea, as well as in inland areas like Nemi.Footnote 28 The evidence from Porta Pia, however, suggests that these wine containers may still have supplied wine to Rome in the early third century AD, as proposed by Arthur (Reference Arthur, Potter and King1997: 315). It is interesting to note that, despite a likely use of wooden barrels for the transport of wine by river, in Umbria amphorae of the Spello type probably continued to be produced and circulate to supply a local market, indicated by their recent discoveries in fourth century AD contexts in the SabinaFootnote 29 and Umbria.Footnote 30 Also the study of the South Etruria Survey material has demonstrated some evidence for the continued use of containers of a very similar typology to the Spello type amphorae, documented in contexts of the late sixth century AD (Patterson et al., 2005).

TYPOLOGY OF THE MONTELABATE AMPHORAE

The amphorae produced at Montelabate were classified into eight types:Footnote 31 types 1–3 have everted band rims, types 4 and 6 have tapered rims, types 5 and 7 have rounded rims and type 8 has an unusual triangular rim. Although no whole vessels were recovered, there are several bases, with diameters varying from 5 to 7.5 cm; most of the bases have an inset underside: there are examples of Lapadula (Reference Lapadula1997) type 1 (Fig. 10.2) and of her types 2.1 and 2.2 (Fig. 10.1–4) and some examples of type 4 (Fig. 10.3).

Fig. 10. Types of amphorae bases (drawing: author).

Type 1 amphorae have a vertical band rim with a cylindrical neck, slightly thickened where the round-arched handles attach. The handles are flattened with three grooves on the upper part and two grooves on the lower part (Fig. 11). Many wasters of this type were collected during the excavation. The diameters vary from 7.5 to 8.5 cm. This type is the most commonly produced at Montelabate, with 24 examples, of which fourteen came from the northern pottery dump in trench 4 (see Appendix). These containers had the largest estimated capacity of around 18–19 L (34–5 sextarii) and correspond to the Ostia III, 369 and Ostia VI, 45 types (Rizzo, Reference Rizzo, Rizzo and Panella2014: 132, pl. 7), found in the late Antonine layers of AD 120–60.Footnote 32

Fig. 11. Types of amphorae produced at Montelabate (drawing: author).

Type 2 amphorae have a slightly everted rounded band rim and a cylindrical neck that thickens where the handles attach. The handles are bent and rounded, with two longitudinal grooves (Fig. 11). The diameter varies from 8 to 8.5 cm; this type is attested by 12 examples, half of which come from the pottery dump in trench 4 but mostly from topsoil layers. The estimated capacity is around 17 L (32 sextarii) and corresponds to the Ostia II, 521 and Ostia VI, 47 types (Panella, Reference Panella1989: 171, figs. 9–10; Rizzo, Reference Rizzo, Rizzo and Panella2014: 132, pl. 8), also found in the late Antonine layers in the northeast area of the Terme del Nuotatore at Ostia. This type is frequently attested in Umbria.Footnote 33

Type 3 amphorae have an everted band rim, tapered at the lip with a groove inside, and a cylindrical neck slightly thickened where the handles attach; the handles are oval with two longitudinal grooves (Fig. 11). The rim diameter ranges from 7.5 to 8.5 cm, and the type is attested by 21 examples. This is certainly a type very commonly produced by the Montelabate kilns, as wasters were found in all of the excavated pottery dumps (see Appendix).Footnote 34 Its estimated capacity is similar to that of type 2.

Type 4 amphorae have an everted band rim with a tapered lip and with the upper attachments of the handles below the rim; the handles are flattened, with two longitudinal grooves (Fig. 11). The diameter varies between 7.5 and 8 cm. Twenty examples were found in the excavations, some of which are overfired wasters. As with type 3, the fragments were found in all of the excavated pottery dumps, indicating that this small container was frequently produced at Montelabate. This type of amphora, with estimated capacity of around 16 L (29 sextarii), is widely attested in Umbria, suggesting a production mainly for a local market.Footnote 35

Type 5 amphorae have a rim with an oval section, slightly thickened, and the upper attachments of the handle are just beneath the rim; the handles are rounded, flattened and have two longitudinal grooves (Fig. 11). The samples come primarily from the pottery dump of trench 4, the rim measures 8 cm in diameter and its shape, reminiscent of Dressel 2–4 amphorae, corresponds to the Ostia VI, 49 type (Rizzo, Reference Rizzo, Rizzo and Panella2014: 132, pl. 8) also documented in Umbria, in particular in the territory around Montelabate, such as at Civitella d'Arna.Footnote 36 Due to their fragmentary nature it is impossible to estimate the capacity, but these containers are of similar size to type 4 amphorae.

Type 6 amphorae have an everted band rim with a rounded lip with a diameter of 7.8–8 cm. The handle has an unusual single longitudinal groove and a flattened oval section (Fig. 11). The fragments discovered during the excavation were found in all of the excavated pottery dumps and include 14 samples, two of which are overfired wasters. This type of container has a small size that cannot be estimated and appears to be a characteristic production of Montelabate, probably for a local market.Footnote 37

Type 7 amphorae have a very short rounded rim with a squared section, cylindrical neck and an oval handle with a central ridge (Fig. 11). The diameter is 9.4 cm, but the fragmentary nature of this type makes it impossible to estimate its capacity. The shape of the rim suggests an influence of the flat-bottomed ‘Empoli’ type amphorae and it is also similar to an example of the ‘Spello’ type from Scoppieto (Speranza, Reference Speranza and Bergamini2011: 303, n.7.5 fig. 7a).Footnote 38

Type 8 amphorae have an unusual triangular rim with a diameter of 7.2–7.5 cm and with the attachment for the handles below the rim, which are flattened with two longitudinal grooves (Fig. 11). There are fragments and wasters from the pottery dump in trench 4 and, like type 6, these containers have a small size that cannot be estimated and appear to be a characteristic production of Montelabate.

To summarize, the variety of amphorae produced indicates that several potters probably shared the kilns, as also confirmed by the minimal standardization of the overall morphology of the amphorae, with characteristic types 6 and 8; and that their individual technical skills varied, as illustrated by the large number of wasters of types 1 and 3 (see Appendix). The large number of amphorae wasters discovered in the same contexts as those of coarseware, discussed below, seems to suggest that the production of amphorae possibly continued in the late antique period. In particular, types 6 and 8 have a smaller dimension and are typologically very similar to samples from Spoleto (Costamagna, Reference Costamagna, Cirelli, Diosono and Patterson2015: 377–8 and fig. I. 5), Mola di MontegelatoFootnote 39 and the middle Tiber valley,Footnote 40 circulating local wine following a distribution network along the Via Flaminia (see below).

Alongside this type of locally produced amphora, other typologies were also discovered in all of the excavated contexts, including the Italian wine amphorae Dressel 6AFootnote 41 and Dressel 2–4.Footnote 42 It is also interesting to note the presence of two rims of Dressel 14A/Beltrán IVA, a type of amphora for fish products from the Iberian Peninsula, made from the Tiberian period to the third century AD.Footnote 43

COARSEWARE PRODUCTION

Once the demand for wine vessels declined, the production at the kilns at Montelabate focused on coarseware and large storage vessels such as dolia and mortaria. It is evident that the potters were not specialized and did not have the technology to produce fineware, but the wasters summarized here testify to the manufacturing of a diverse range of products for the local market. Much of this production, dating to between the second and the fifth century AD, is similar to pottery found in the area of Civitella d'Arna, Gubbio and the villa at Poggio Gramignano near Lugnano in Teverina, showing the strength of economic relations in the area.

Two wasters of dolia were recovered from kiln 1 with a diameter of 35 cm and a broad flat angular rimFootnote 44 (Fig. 12.1), and in trench 5 a deformed mortarium rim was recovered (Fig. 12.3, diameter 38 cm), which is similar to examples from the area of Civitella d'Arna (Donnini and Rosi Bonci, Reference Donnini and Rosi Bonci2008: 98, site 27, pl. XXIX, n. 1180) and Spello, Case Silvi (Sensi, Reference Sensi1983: 125, pl. 11.c).

Fig. 12. Other amphorae types and coarseware production (drawing: author).

Also of note from kiln 3 and the pottery dump in trench 5 are three wasters of jugs with thickened rounded rims, short necks and single handles with an oval section and a central groove (Fig. 12.4). The kilns at Montelabate were also used to produce a type of jar with a broad rim angled upwards and two handles with the same section as the jugs (Fig. 12.5).Footnote 45 There are also wasters of incensaria, in the form of carinated bowls with an everted rounded or thickened rounded rim, similar to those made at Gubbio (Cipollone, Reference Cipollone1983; Whitehead, Reference Whitehead, Malone and Stoddart1994: 199, fig. 6.11, 1–3), dated to the second century AD.

Characteristic of a third-century AD production are the bowls which imitate African products. Among the wasters discovered were overfired and underfired large dishes with diameters ranging between 30 and 37 cm, such as the bowl with a vertical rim and rounded wall imitating the form Hayes 26, type 12 Bonifay (Fig. 13.1–2).Footnote 46

Fig. 13. Coarseware production from Montelabate (drawing: author).

The later production, dating to the fourth to fifth centuries AD, consists mostly of coarseware and colour-coated dishes with thickened squared in-turned rims and a straight flaring wall, such as the wasters from kiln 2b (Fig.13.7–8).Footnote 47 Several examples from kiln 2b and the pottery dump in trench 5 (Fig. 13.3–5) imitate the African form Hayes 61A/B4, dated to the first half of the fifth century AD.Footnote 48 A type of dish in colour-coated ware from the bottom of kiln 1 (Fig. 13.6) has a parallel from the villa at Lugnano in Teverina (Martin, Reference Martin, Soren and Soren1999a: 255, fig. 185.60).

The manufacturing complex at Montelabate provides new evidence for the economy of Regio VI and can be included, together with Scoppieto, among Umbria's important production centres. It demonstrates a complex system of amphora production alongside the later production of coarseware, which completely replaced it: it falls within the categories of ‘estate production’ and ‘nucleated workshop industry’ in Peacock's classification (Reference Peacock1982: 9–10).Footnote 49 The former was connected to the economic needs of an agricultural estate, such as tiles, bricks and wine containers; although there are no traces of a villa near Montelabate. The latter refers to a cluster of individual workshops where pottery-making was a major activity due to the availability of raw materials and market demand, although they did not produce high-quality ceramics.

Determining the rate production of a site can be a difficult task: certainly in winter the cold, wet weather would have slowed down the process of drying and firing the pottery. As such, we can to a degree assume a seasonality of manufacture, with the production rate increasing in the drier period of the year. In Egypt, for instance, papyri provide some figures for the amphora-forming rate: a text dated to the mid-third century AD from the Zenon Archive contained the complaints of two potters over the loss of approximately 30 vessels resulting from the workspace being unavailable for four days (Gallimore, Reference Gallimore2010: 169). This suggests a daily rate of around eight amphorae, though the figure may vary depending on the size of the amphora. Any hypothesis on the status of potters, whether they were freedmen or slaves, remains speculative due to a lack of epigraphic evidence.Footnote 50 Potters may also have worked part time in agriculture. Evidence from the pottery workshop at Pompeii in Via di Nocera (I.20.2–3) suggests that during the eruption the workers may have been busy with the harvest, as shown by the use of the two kilns as a storage area (Peña and McCallum, Reference Peña and McCallum2009: 72).

The production of standardized coarseware probably required a relatively less intense production rate, which in turn supports the hypothesis that at Montelabate the kilns were always in use, producing amphorae and other ceramics until the third century AD. As a consequence of market contraction and a change in demand we can observe a substantial reduction in activities in the workshop as there was no longer the requirement for the mass production of amphorae. However, Montelabate's geographical position and available resources allowed for continuity of use of the kilns with a different manufacturing strategy from the fourth century AD.

The valley of Montelabate lay in a frontier territory: the hills to the west were rich in woodlands dividing it from Gubbio, whilst the flat fertile fields were suitable for agricultural exploitation; connectivity was ensured by the river Ventia and by an internal road that joined the Via Flaminia, all of which favoured economic growth. The ecology of the region was documented by Pliny the Younger (Epistles 5.4–13) who describes it as being rich in hills and forests, ‘montes … procera nemora’, with fertile hills covered in vineyards (vinea); he also noted that the Tiber was navigable for trade in the winter and spring.

The cultivation of vines was crucial for the landscape in which the workshop was located, and the presence of three kilns at Montelabate producing amphorae suggests an intensive cultivation. As noted by Braconi (Reference Braconi, Ciacci, Rendini and Zifferero2012) using the texts of Pliny and Cato (De re rustica 137), there were different methods for growing vines in Umbria: the arbusta, using trees as supports, and the vinea, in which wooden poles were driven into the ground, as in modern times, allowing for extensive vine growth. The latter was the method most probably used in the valley of Montelabate. Moreover, in contrast to Pliny's villa, we can assume that the vine and wine production, requiring intensive and specialized agricultural exploitation of the land, was the work of farmers living in the landscape rather than slaves, as the open landscape was not controlled by a villa, implying a different model for the economy of production. This land occupation model is confirmed by the results of the field walking survey conducted in 2010 (Stoddart et al., Reference Stoddart, Baroni, Ceccarelli, Cifani, Clackson, Ferrara, della Giovampaola, Fulminante, Licence, Malone, Mattacchioni, Mullen, Nomi, Pettinelli, Redhouse and Whitehead2012) across the entire valley towards the river Ventia, which identified a series of small and larger farms, dating from the early first century AD, some of which continued to be occupied until the fifth century AD. The findings suggest that there was a ranking size of farm structures occupying the territory, perhaps with free labourers moving to meet the seasonal needs of agriculture, even those working in the manufacture of pottery. This model of seasonal employment for farmers is attested by Suetonius (Vespasian 1.4): one of Vespasian's ancestors, the father of Titus Flavius Petri, was a contractor for the labourers coming every year from Umbria and Sabina. A similar pattern of occupation has been identified in the territory of Civitella d'Arna, where only a substantial villa site was discovered at Lidarno, whilst there were several rural sites about 5 km south of the valley of Montelabate (Donnini and Rosi Bonci, Reference Donnini and Rosi Bonci2008: 59, dating from the first to the fifth century AD). The same small and medium rural settlement model, in a territory not subject to centuriation, with farms run by free labourers was identified by the field walking survey in the territory of Gubbio and by the excavation of the site at San Marco Romano (Whitehead, Reference Whitehead, Malone and Stoddart1994: 195–7).

CONCLUSION

The kilns excavated at Montelabate provide firm evidence for the production of flat-bottomed wine amphorae, and the varying types of morphology are clearly attested by over 400 fragments, the majority of which are wasters. The importance of this workshop is therefore evident, as it provides a better understanding of one of the centres of production of this type of amphora in Regio VI when considered together with SpelloFootnote 51 and the recent discovery at Torgiano.Footnote 52 The large workshop at Montelabate has no direct parallels in Umbria and may have had a reasonably broad network of distribution over a long period of time (from the first through to the fourth or fifth century AD), and from an economic perspective the kilns are an indicator of a clear structuring of the territory for the large-scale production of wine.

At local scale, Montelabate wine amphorae were distributed by road southwards in the territory of Civitella d'Arna (Donnini and Rosi Bonci, Reference Donnini and Rosi Bonci2008: 46–7, site 10, plates VII–IX) and possibly to the north reaching as far as the Villa of Pliny at San Giustino.Footnote 53 It is also highly probable that the Montelabate products reached Gubbio,Footnote 54 whose function as a central market has been clearly identified by Manconi and Whitehead (Reference Manconi, Whitehead, Malone and Stoddart1994: 186). The town had its own production of ceramics, as previously discussed, but no evidence for wine production has been identified, suggesting that the flat-bottomed amphorae discovered were all imported.

The Tiber constituted the preferred distribution network for the wine containers which mostly focused on the market of Rome: river connectivity reached Perugia, where the main port has been identified at the confluence of the Tiber and Chiascio rivers, near Pontenuovo di Torgiano (Bergamini, Reference Bergamini, Coarelli and Patterson2008b: 294–5; Speranza, Reference Speranza and Bergamini2011: 286). Along the stretch of the Tiber between Todi and Ocriculum, traces of docks are well documented, some of which are still in use in modern times.Footnote 55 The villa of Lugnano in Teverina was undoubtedly used as a place to sort goods heading along the river, but the inner routes were also heavily used, such as that running from Ocriculum on the left bank of the Tiber towards Sabina Tiberina and which at Forum Novum crossed another route leading to the Via Flaminia,Footnote 56 a network that continued in the late antique period.

Trade followed the same route north: according to Dionysius (3.44.1), the Tiber was navigable upstream to the springs. The most important evidence is offered by the numerous amphorae from Spain and Africa, as well as other imported African products discovered in the Upper Tiber valley, as far away as the villa of Pliny at San Giustino where the presence of a river trading port has been suggested.Footnote 57 The field walking survey in the territory of Civitella d'Arna identified both amphorae and African Red Slip ware (Donnini and Rosi Bonci, Reference Donnini and Rosi Bonci2008).Footnote 58 In the Montelabate valley, the field walking survey recovered imported materials such as rims of African IFootnote 59 near the Ventia river at sites 49 and 78 (Figs 14 and 12.6). Only a fragment of a lamp in African Red Slip was discovered in topsoil at the kilns site, where it is also worth noting the presence of a spatheion (Fig. 12.3) dating to the first half of the fifth century AD.Footnote 60

Fig. 14. Map of the Roman sites identified by the field walking survey (drawing: author).

This suggests that Montelabate was still marginally part of a system of commercial contacts until the late fourth–fifth century AD, but the production in the kilns indicates a contraction in the scale and organizational complexity of manufacturing connected with a demand for modest products, such as the coarseware dishes with thickened in-turned rims and straight flaring walls that circulated to some extent to supply a local and regional market.

APPENDIX

Table A1. List of amphorae by type.