1. Introduction

Slip behaviour in complex fluids has been attributed to various microscopic phenomena such as chain detachment/desorption at the polymer–wall interface in polymer melts (Hatzikiriakos Reference Hatzikiriakos2012), migration/depletion of disperse phase away from the vicinity of the solid boundaries in suspensions (Vand Reference Vand1948), and elastic deformation of the suspended soft particles lying on the smooth solid boundaries (Meeker, Bonnecaze & Cloitre Reference Meeker, Bonnecaze and Cloitre2004b) in pastes – yield-stress fluids. In the present study, however, we rather investigate the macroscopic consequences of slip on hydrodynamic features of yield-stress fluid flows, in order to form a bridge over these two distinct scales.

In experiments, roughened (e.g. using sandpapers) or chemically treated surfaces are usually used to suppress slip in measurements of yield-stress fluid flows. For instance, Christel et al. (Reference Christel, Yahya, Albert and Antoine2012) proposed a polymethyl methacrylate (known as PMMA) treatment to reduce slip by exciting positive surface charges providing electrostatic interactions and squashing the lubricating layer. This is important since in a great number of laboratory experiments, polymethyl methacrylate is used due to its transparency properties which enable flow visualizations. In industrial scales/processes, however, chemical treatments are not always feasible, and therefore it is crucial to analyse the hydrodynamic consequences of sliding flows. Moreover, slip alters rheometric measurements, causing rheological properties of the samples to be inaccurately evaluated, sometimes even by one order of magnitude (Poumaere et al. Reference Poumaere, Moyers-González, Castelain and Burghelea2014). This issue has been discussed extensively in the literature, for instance recently by Medina-Bañuelos et al. (Reference Medina-Bañuelos, Marín-Santibáñez, Pérez-González, Malik and Kalyon2017, Reference Medina-Bañuelos, Marín-Santibáñez, Pérez-González and Kalyon2019). Hence, it would be constructive to have a generic analysis framework of sliding flows in yield-stress fluids, and this is the aim of the present paper.

In the present study, we formulate the well known ‘stick–slip’ law for yield-stress fluids beyond one-dimensional (1-D) rheometric flows and then generalize the previously proposed numerical algorithm (Roquet & Saramito Reference Roquet and Saramito2008; Muravleva Reference Muravleva2018) based on the augmented Lagrangian method for attacking this kind of problem. Theoretical tools are developed in the presence of slip. The whole framework is first benchmarked by a simple channel Poiseuille flow. Then we proceed to investigate flows in complex geometries: the creeping flows about a circular cylinder and the pressure-driven flows in model and randomized porous media.

1.1. General slip law for yield-stress fluids

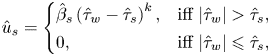

Characterizing the slip behaviour of yield-stress fluids has been the main objective of a large number of studies from theoretical attempts to experimental measurements. Meeker et al. (Reference Meeker, Bonnecaze and Cloitre2004b) and Piau (Reference Piau2007) tried to theoretically describe the slip origin in soft particle pastes/microgels from an elastohydrodynamic perspective. Rheometric tests with slippery plates in the cone–plate/plate–plate geometries have been conducted to quantify the slip behaviours of yield-stress fluids ranging from Carbopol gels to emulsions (Meeker, Bonnecaze & Cloitre Reference Meeker, Bonnecaze and Cloitre2004a; Meeker et al. Reference Meeker, Bonnecaze and Cloitre2004b; Poumaere et al. Reference Poumaere, Moyers-González, Castelain and Burghelea2014; Zhang et al. Reference Zhang, Lorenceau, Bourouina, Basset, Oerther, Ferrari, Rouyer, Goyon and Coussot2018). Moreover, very recently, in a series of experiments using optical coherence tomography (known as OCT) and particle tracking velocimetry (known as PTV), Daneshi et al. (Reference Daneshi, Pourzahedi, Martinez and Grecov2019) characterized the slip behaviour of Carbopol gel (a model ‘simple’ yield-stress fluid) inside a capillary tube. The sliding characteristics of yield-stress fluids observed in all the mentioned 1-D experimental studies can be summarized in a general slip law as

\begin{equation} \hat{u}_{{s}} = \left\{\begin{array}{@{}ll} \hat{\beta}_s \left( \hat{\tau}_{w} - \hat{\tau}_{s} \right)^k, & \text{iff}\ \vert \hat{\tau}_{w} \vert > \hat{\tau}_s, \\ 0, & \text{iff}\ \vert \hat{\tau}_{w} \vert \leqslant \hat{\tau}_s, \end{array} \right. \end{equation}

\begin{equation} \hat{u}_{{s}} = \left\{\begin{array}{@{}ll} \hat{\beta}_s \left( \hat{\tau}_{w} - \hat{\tau}_{s} \right)^k, & \text{iff}\ \vert \hat{\tau}_{w} \vert > \hat{\tau}_s, \\ 0, & \text{iff}\ \vert \hat{\tau}_{w} \vert \leqslant \hat{\tau}_s, \end{array} \right. \end{equation}

usually termed as the ‘stick–slip’ law, where ![]() $\hat {u}_{{s}}$ is the slip velocity on the solid surface and

$\hat {u}_{{s}}$ is the slip velocity on the solid surface and ![]() $\hat {\tau }_w$ is the shear stress at the solid boundaries. The sliding threshold is called the sliding yield stress –

$\hat {\tau }_w$ is the shear stress at the solid boundaries. The sliding threshold is called the sliding yield stress – ![]() $\hat {\tau }_s$. The slip coefficient and the power index are designated by

$\hat {\tau }_s$. The slip coefficient and the power index are designated by ![]() $\hat {\beta }_s$ and

$\hat {\beta }_s$ and ![]() $k$, respectively. Hence,

$k$, respectively. Hence, ![]() $\hat {\beta }_s$ has the dimension of

$\hat {\beta }_s$ has the dimension of ![]() $m^{2k+1}/N^k.s$ or

$m^{2k+1}/N^k.s$ or ![]() $m/Pa^k.s$. Its physical interpretation (for the case

$m/Pa^k.s$. Its physical interpretation (for the case ![]() $k=1$) is the slip length over the local effective viscosity of the fluid,

$k=1$) is the slip length over the local effective viscosity of the fluid, ![]() $\hat {\ell }_s / \hat {\mu }_{eff}$. In the entire paper, quantities with a ‘hat’ symbol (

$\hat {\ell }_s / \hat {\mu }_{eff}$. In the entire paper, quantities with a ‘hat’ symbol (![]() $\hat {\cdot }$) are dimensional and others are dimensionless.

$\hat {\cdot }$) are dimensional and others are dimensionless.

For a deeper understanding of the physical meaning of the slip law (1.1), we consider the simple unidirectional channel Poiseuille flow in the presence of slip of a viscoplastic fluid,

\begin{equation} \left\{\begin{array}{@{}ll} \hat{\tau}_{xy} = \hat{K} \displaystyle \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} \left[ \text{abs}\left( \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} \right) \right]^{n-1} + \hat{\tau}_y \,\text{sgn} \left( \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} \right) & \mbox{iff}\ \vert \hat{\tau}_{xy} \vert > \hat{\tau}_y, \\ \displaystyle \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} = 0 & \mbox{iff}\ \vert \hat{\tau}_{xy} \vert \leqslant \hat{\tau}_y, \end{array} \right. \end{equation}

\begin{equation} \left\{\begin{array}{@{}ll} \hat{\tau}_{xy} = \hat{K} \displaystyle \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} \left[ \text{abs}\left( \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} \right) \right]^{n-1} + \hat{\tau}_y \,\text{sgn} \left( \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} \right) & \mbox{iff}\ \vert \hat{\tau}_{xy} \vert > \hat{\tau}_y, \\ \displaystyle \dfrac{\text{d} \hat{u}}{\text{d} \hat{y}} = 0 & \mbox{iff}\ \vert \hat{\tau}_{xy} \vert \leqslant \hat{\tau}_y, \end{array} \right. \end{equation}

where ![]() $\hat {K} (\textrm {Pa} \cdot s^n)$ is the consistency of the fluid and

$\hat {K} (\textrm {Pa} \cdot s^n)$ is the consistency of the fluid and ![]() $n$ the power-index (Herschel–Bulkley model),

$n$ the power-index (Herschel–Bulkley model), ![]() $\hat {u}$ the streamwise velocity,

$\hat {u}$ the streamwise velocity, ![]() $\hat {\tau }_y$ the material's yield stress,

$\hat {\tau }_y$ the material's yield stress, ![]() $\hat {\tau }_{xy}$ the shear stress and

$\hat {\tau }_{xy}$ the shear stress and ![]() $\text {sgn}(\cdot )$ and

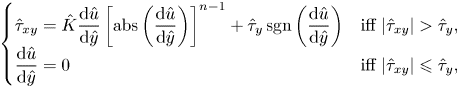

$\text {sgn}(\cdot )$ and ![]() $\text {abs}(\cdot )$ are the sign and absolute value functions. Figure 1 represents the slip law schematically. When the applied pressure gradient is small enough, the wall shear stress (

$\text {abs}(\cdot )$ are the sign and absolute value functions. Figure 1 represents the slip law schematically. When the applied pressure gradient is small enough, the wall shear stress (![]() $\hat {\tau }_w$) lies below the sliding yield stress (figure 1a) and the slip velocity is zero. Since

$\hat {\tau }_w$) lies below the sliding yield stress (figure 1a) and the slip velocity is zero. Since ![]() $\hat {\tau }_s$ is always less than the material's yield stress, then there is no flow in the channel. When the pressure gradient is increased beyond

$\hat {\tau }_s$ is always less than the material's yield stress, then there is no flow in the channel. When the pressure gradient is increased beyond ![]() $({\rm \Delta} \hat {p}/\hat {L})_c$ where subscript ‘

$({\rm \Delta} \hat {p}/\hat {L})_c$ where subscript ‘![]() $_c$’ indicates the critical value, the wall shear stress grows beyond

$_c$’ indicates the critical value, the wall shear stress grows beyond ![]() $\hat {\tau }_s$ and the fluid slides over the walls. If the wall shear stress is still less than

$\hat {\tau }_s$ and the fluid slides over the walls. If the wall shear stress is still less than ![]() $\hat {\tau }_y$, then the material moves as a sliding unyielded plug with a constant velocity in the entire gap (see figure 1b). When the pressure gradient is increased, at some point, the wall shear stress exceeds the fluid yield stress and the sheared/yielded regions appear, which at the same time slide over the walls – see figure 1(c). Yet, in the vicinity of the centreline, the shear stress drops below the yield stress and a core unyielded region is formed. The flows corresponding to figures 1(b) and 1(c) are usually termed the fully plugged regime and the deformation regime, respectively.

$\hat {\tau }_y$, then the material moves as a sliding unyielded plug with a constant velocity in the entire gap (see figure 1b). When the pressure gradient is increased, at some point, the wall shear stress exceeds the fluid yield stress and the sheared/yielded regions appear, which at the same time slide over the walls – see figure 1(c). Yet, in the vicinity of the centreline, the shear stress drops below the yield stress and a core unyielded region is formed. The flows corresponding to figures 1(b) and 1(c) are usually termed the fully plugged regime and the deformation regime, respectively.

Figure 1. Schematic of the sliding channel flow of a yield-stress fluid; the ![]() $x$-axis is aligned and placed at the axial centreline of the channel which is formed by the two infinite parallel plates separated by the gap

$x$-axis is aligned and placed at the axial centreline of the channel which is formed by the two infinite parallel plates separated by the gap ![]() $\hat {H}$ and the

$\hat {H}$ and the ![]() $y$-axis is in the wall-normal direction: (a) when

$y$-axis is in the wall-normal direction: (a) when ![]() $\hat {\tau }_w \leqslant \hat {\tau }_s$ there is no flow, (b) when

$\hat {\tau }_w \leqslant \hat {\tau }_s$ there is no flow, (b) when ![]() $\hat {\tau }_s < \hat {\tau }_w \leqslant \hat {\tau }_y$ then the fluid in the whole gap slides as an unyielded plug, (c) when

$\hat {\tau }_s < \hat {\tau }_w \leqslant \hat {\tau }_y$ then the fluid in the whole gap slides as an unyielded plug, (c) when ![]() $\hat {\tau }_y < \hat {\tau }_w$ then the fluid in the vicinity of the walls (

$\hat {\tau }_y < \hat {\tau }_w$ then the fluid in the vicinity of the walls (![]() $\hat {y}_p <\hat {y}$ where

$\hat {y}_p <\hat {y}$ where ![]() $\hat {\tau }_y < \hat {\tau }_{xy}$) yields and at the same time slides over the walls. There is a core unyielded region as well (

$\hat {\tau }_y < \hat {\tau }_{xy}$) yields and at the same time slides over the walls. There is a core unyielded region as well (![]() $\hat {y} \leqslant \hat {y}_p$).

$\hat {y} \leqslant \hat {y}_p$).

In the present study, the objective is to systematically address the effect of slip on yield-stress fluid flows and its consequences on the yield limit; not only by conducting numerical simulations, but also by forming a theoretical framework for analysing this type of problem. Although some attempts have been made to solve simple rheometric flows in previous years (Philippou, Kountouriotis & Georgiou Reference Philippou, Kountouriotis and Georgiou2016; Panaseti & Georgiou Reference Panaseti and Georgiou2017; Damianou, Panaseti & Georgiou Reference Damianou, Panaseti and Georgiou2019), still the lack of generic numerical implementation frameworks (especially non-regularized methods) and the absence of adequate theoretical frameworks to attack sliding yield-stress fluid flows are discernible. Hence, in what follows, we aim to partially fill this gap in the literature. Beyond that, we study complex sliding flows such as particle sedimentation and pressure-driven flows in porous media within these frameworks.

The outline of the paper is as follows. In § 2, we set out the slip law beyond 1-D for the yield-stress fluid flows and generalize the numerical algorithm previously proposed for simple 1-D problems. We then benchmark the numerical algorithm for simple channel Poiseuille flow in § 3 and derive some theoretical tools for investigating the sliding flows. This will be followed by addressing the sliding flow about a circular particle and the aspects of the particle yield limit in § 4. The next two sections are devoted to the sliding flows in porous media: in § 5 some general hints are made by studying the flow through model porous media and in § 6 some deeper investigations are carried out by performing numerical simulations in randomized porous media. Finally, some conclusions are drawn in the closing section § 7.

2. Slip law and the numerical algorithm beyond 1-D

In this section, we set out and formulate a sample problem of sliding flow of a yield-stress fluid and generalize the slip law and numerical algorithm for solving such problems beyond 1-D. In what follows, we mainly assume that ![]() $n=1$ (Bingham model). Later in appendix C, we will address how the present framework can be expanded to encompass the other ‘simple’ yield-stress rheological models, e.g. Herschel–Bulkley. However, the majority of the physical discussions (e.g. the yield limit) in the next sections are independent of the value of

$n=1$ (Bingham model). Later in appendix C, we will address how the present framework can be expanded to encompass the other ‘simple’ yield-stress rheological models, e.g. Herschel–Bulkley. However, the majority of the physical discussions (e.g. the yield limit) in the next sections are independent of the value of ![]() $n$. We will come back to this point in § 7.

$n$. We will come back to this point in § 7.

Problem ![]() $\mathbb {P}$. We consider the Stokes flow of a Bingham fluid in

$\mathbb {P}$. We consider the Stokes flow of a Bingham fluid in ![]() $\varOmega \setminus \bar {X}$ (see figure 2) as follows:

$\varOmega \setminus \bar {X}$ (see figure 2) as follows:

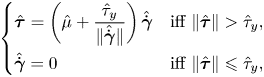

\begin{gather}\left\{\begin{array}{@{}ll} \hat{\boldsymbol{\tau}} = \left( \hat{\mu} + \displaystyle{\dfrac{\hat{\tau}_y}{\Vert \hat{\dot{\boldsymbol{\gamma}}} \Vert}} \right) \hat{\dot{\boldsymbol{\gamma}}} & \mbox{iff}\ \Vert \hat{\boldsymbol{\tau}} \Vert > \hat{\tau}_y, \\ \hat{\dot{\boldsymbol{\gamma}}} = 0 & \mbox{iff}\ \Vert \hat{\boldsymbol{\tau}} \Vert \leqslant \hat{\tau}_y, \end{array} \right. \end{gather}

\begin{gather}\left\{\begin{array}{@{}ll} \hat{\boldsymbol{\tau}} = \left( \hat{\mu} + \displaystyle{\dfrac{\hat{\tau}_y}{\Vert \hat{\dot{\boldsymbol{\gamma}}} \Vert}} \right) \hat{\dot{\boldsymbol{\gamma}}} & \mbox{iff}\ \Vert \hat{\boldsymbol{\tau}} \Vert > \hat{\tau}_y, \\ \hat{\dot{\boldsymbol{\gamma}}} = 0 & \mbox{iff}\ \Vert \hat{\boldsymbol{\tau}} \Vert \leqslant \hat{\tau}_y, \end{array} \right. \end{gather}

where ![]() $\hat {p}$ is the pressure,

$\hat {p}$ is the pressure, ![]() $\hat {\boldsymbol {\tau }}$ the deviatoric stress tensor,

$\hat {\boldsymbol {\tau }}$ the deviatoric stress tensor, ![]() $\hat {\rho } \hat {\boldsymbol {f}}$ the body force,

$\hat {\rho } \hat {\boldsymbol {f}}$ the body force, ![]() $\hat {\rho }$ the fluid density and

$\hat {\rho }$ the fluid density and ![]() $\hat {\dot {\boldsymbol {\gamma }}}$ is the rate of deformation tensor. Without loss of generality, we consider no-slip and no-penetration boundary conditions on

$\hat {\dot {\boldsymbol {\gamma }}}$ is the rate of deformation tensor. Without loss of generality, we consider no-slip and no-penetration boundary conditions on ![]() $\partial \varOmega$ as

$\partial \varOmega$ as ![]() $\hat {\boldsymbol {u}} = \hat {\boldsymbol {u}}_0$ and the slip boundary condition,

$\hat {\boldsymbol {u}} = \hat {\boldsymbol {u}}_0$ and the slip boundary condition,

\begin{equation} \hat{u}_{{s}} = \hat{\boldsymbol{u}}_{{ns}} \boldsymbol{\cdot} \boldsymbol{t} - \boldsymbol{\delta} \hat{\boldsymbol{u}} \boldsymbol{\cdot} \boldsymbol{t} = \left\{ \begin{array}{@{}ll} \hat{\beta}_s \hat{\varLambda} \left( 1 - \displaystyle\dfrac{\hat{\tau}_{s}}{\vert \hat{\varLambda} \vert} \right), & \text{iff}\ \vert \hat{\varLambda} \vert > \hat{\tau}_s, \\ 0, & \text{iff}\ \vert \hat{\varLambda} \vert \leqslant \hat{\tau}_s, \end{array} \right. \end{equation}

\begin{equation} \hat{u}_{{s}} = \hat{\boldsymbol{u}}_{{ns}} \boldsymbol{\cdot} \boldsymbol{t} - \boldsymbol{\delta} \hat{\boldsymbol{u}} \boldsymbol{\cdot} \boldsymbol{t} = \left\{ \begin{array}{@{}ll} \hat{\beta}_s \hat{\varLambda} \left( 1 - \displaystyle\dfrac{\hat{\tau}_{s}}{\vert \hat{\varLambda} \vert} \right), & \text{iff}\ \vert \hat{\varLambda} \vert > \hat{\tau}_s, \\ 0, & \text{iff}\ \vert \hat{\varLambda} \vert \leqslant \hat{\tau}_s, \end{array} \right. \end{equation}

on ![]() $\partial X$, where

$\partial X$, where ![]() $\hat {u}_{{s}}$ is the slip velocity,

$\hat {u}_{{s}}$ is the slip velocity, ![]() $\hat {\boldsymbol {u}}_{{ns}}$ the velocity of the solid boundary

$\hat {\boldsymbol {u}}_{{ns}}$ the velocity of the solid boundary ![]() $\partial X$ and

$\partial X$ and ![]() $\boldsymbol {\delta } \hat {\boldsymbol {u}}$ is the restriction of

$\boldsymbol {\delta } \hat {\boldsymbol {u}}$ is the restriction of ![]() $\hat {\boldsymbol {u}}$ on

$\hat {\boldsymbol {u}}$ on ![]() $\partial X$:

$\partial X$: ![]() $\hat {\boldsymbol {u}} \to \boldsymbol {\delta } \hat {\boldsymbol {u}}$ as

$\hat {\boldsymbol {u}} \to \boldsymbol {\delta } \hat {\boldsymbol {u}}$ as ![]() $\hat {\boldsymbol {x}} \to \partial X$. The value of the tangential traction vector (i.e. tangential force per unit area on the solid surface) is shown by

$\hat {\boldsymbol {x}} \to \partial X$. The value of the tangential traction vector (i.e. tangential force per unit area on the solid surface) is shown by ![]() $\hat {\varLambda } = [ ( - \hat {p} \boldsymbol {1} + \hat {\boldsymbol {\tau }} ) \boldsymbol {\cdot } \boldsymbol {n} ] \boldsymbol {\cdot } \boldsymbol {t}$, where the normal and tangential unit vectors to the solid surface

$\hat {\varLambda } = [ ( - \hat {p} \boldsymbol {1} + \hat {\boldsymbol {\tau }} ) \boldsymbol {\cdot } \boldsymbol {n} ] \boldsymbol {\cdot } \boldsymbol {t}$, where the normal and tangential unit vectors to the solid surface ![]() $\partial X$ are represented by

$\partial X$ are represented by ![]() $\boldsymbol {n}$ and

$\boldsymbol {n}$ and ![]() $\boldsymbol {t}$, respectively. The no-penetration condition on

$\boldsymbol {t}$, respectively. The no-penetration condition on ![]() $\partial X$ reads

$\partial X$ reads ![]() $\boldsymbol {\delta }\hat {\boldsymbol {u}} \boldsymbol {\cdot } \boldsymbol {n} = \hat {\boldsymbol {u}}_{{ns}} \boldsymbol {\cdot } \boldsymbol {n}$.

$\boldsymbol {\delta }\hat {\boldsymbol {u}} \boldsymbol {\cdot } \boldsymbol {n} = \hat {\boldsymbol {u}}_{{ns}} \boldsymbol {\cdot } \boldsymbol {n}$.

Figure 2. Schematic of the problem ![]() $\mathbb {P}$. The full domain is denoted by

$\mathbb {P}$. The full domain is denoted by ![]() $\varOmega$, and the solid object on which the flow slides in designated by

$\varOmega$, and the solid object on which the flow slides in designated by ![]() $X$. The red arrows show the outward unit normal vectors of the solid surface

$X$. The red arrows show the outward unit normal vectors of the solid surface ![]() $\partial X$. The boundary of the full domain is

$\partial X$. The boundary of the full domain is ![]() $\partial \varOmega$.

$\partial \varOmega$.

Without loss of generality, we fixed ![]() $k$ at unity in the slip law (2.3) and will do so in the rest of the present study. This is supported by experimental observations as well. Seth et al. (Reference Seth, Locatelli-Champagne, Monti, Bonnecaze and Cloitre2012) validated the slip power index of unity for emulsions contacting non-adhering surfaces. Moreover, in separate experimental studies, Poumaere et al. (Reference Poumaere, Moyers-González, Castelain and Burghelea2014) and Daneshi et al. (Reference Daneshi, Pourzahedi, Martinez and Grecov2019) reported

$k$ at unity in the slip law (2.3) and will do so in the rest of the present study. This is supported by experimental observations as well. Seth et al. (Reference Seth, Locatelli-Champagne, Monti, Bonnecaze and Cloitre2012) validated the slip power index of unity for emulsions contacting non-adhering surfaces. Moreover, in separate experimental studies, Poumaere et al. (Reference Poumaere, Moyers-González, Castelain and Burghelea2014) and Daneshi et al. (Reference Daneshi, Pourzahedi, Martinez and Grecov2019) reported ![]() $k\approx 1$ for the pressure-driven flows of Carbopol gels with different concentrations and stirring rates during the sample preparation. However, experiments have also revealed that

$k\approx 1$ for the pressure-driven flows of Carbopol gels with different concentrations and stirring rates during the sample preparation. However, experiments have also revealed that ![]() $k \neq 1$ in some cases (Piau Reference Piau2007; Medina-Bañuelos et al. Reference Medina-Bañuelos, Marín-Santibáñez, Pérez-González, Malik and Kalyon2017, Reference Medina-Bañuelos, Marín-Santibáñez, Pérez-González and Kalyon2019). We will discuss these cases in appendix C, as the main objectives/conclusions of the present study are independent of the value of

$k \neq 1$ in some cases (Piau Reference Piau2007; Medina-Bañuelos et al. Reference Medina-Bañuelos, Marín-Santibáñez, Pérez-González, Malik and Kalyon2017, Reference Medina-Bañuelos, Marín-Santibáñez, Pérez-González and Kalyon2019). We will discuss these cases in appendix C, as the main objectives/conclusions of the present study are independent of the value of ![]() $k$.

$k$.

2.1. Numerical algorithm

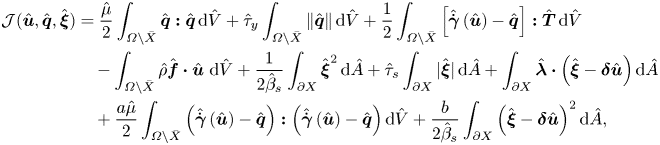

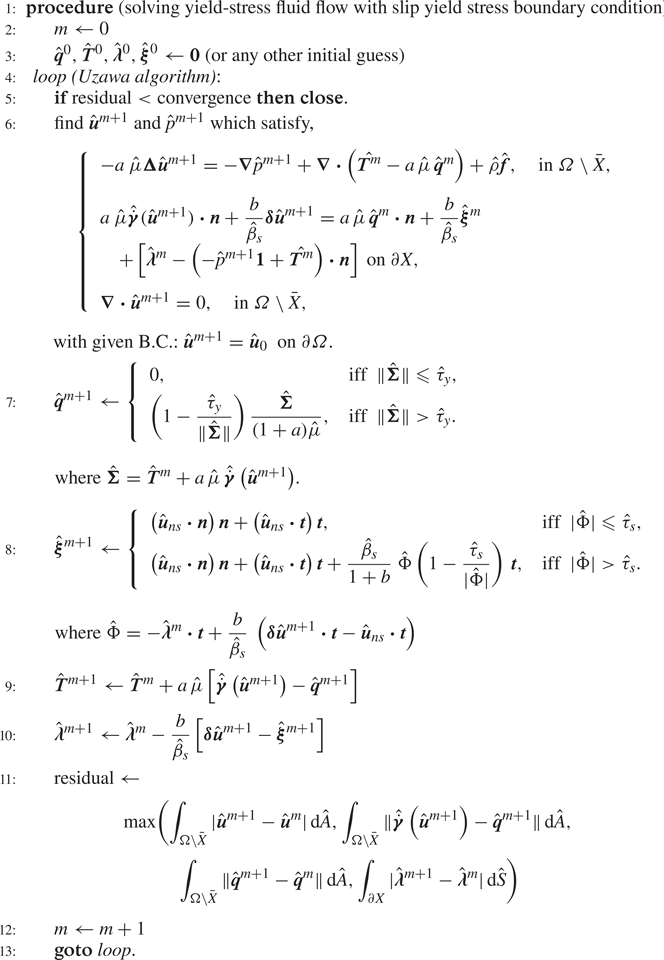

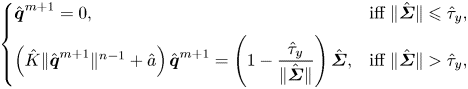

The minimization principle for the sliding problem ![]() $\mathbb {P}$ can be derived as

$\mathbb {P}$ can be derived as

\begin{align} \mathcal{J}(\hat{\boldsymbol{u}}) & = \frac{\hat{\mu}}{2} \int_{\varOmega \setminus \bar{X}} \hat{\dot{\boldsymbol{\gamma}}} (\hat{\boldsymbol{u}}) \boldsymbol{:} \hat{\dot{\boldsymbol{\gamma}}} (\hat{\boldsymbol{u}}) \,\text{d}\hat{V} + \hat{\tau}_y \int_{\varOmega \setminus \bar{X}} \Vert \hat{\dot{\boldsymbol{\gamma}}} (\hat{\boldsymbol{u}}) \Vert \,\text{d}\hat{V} - \int_{\varOmega \setminus \bar{X}} \hat{\rho} \hat{\boldsymbol{f}} \boldsymbol{\cdot} \hat{\boldsymbol{u}} \,\text{d} \hat{V} \nonumber\\ &\quad + \frac{1}{2 \hat{\beta}_s} \int_{\partial X} \hat{u}_s^2 \,\text{d}\hat{A} + \hat{\tau}_s \int_{\partial X} \vert \hat{u}_s \vert \,\text{d}\hat{A}. \end{align}

\begin{align} \mathcal{J}(\hat{\boldsymbol{u}}) & = \frac{\hat{\mu}}{2} \int_{\varOmega \setminus \bar{X}} \hat{\dot{\boldsymbol{\gamma}}} (\hat{\boldsymbol{u}}) \boldsymbol{:} \hat{\dot{\boldsymbol{\gamma}}} (\hat{\boldsymbol{u}}) \,\text{d}\hat{V} + \hat{\tau}_y \int_{\varOmega \setminus \bar{X}} \Vert \hat{\dot{\boldsymbol{\gamma}}} (\hat{\boldsymbol{u}}) \Vert \,\text{d}\hat{V} - \int_{\varOmega \setminus \bar{X}} \hat{\rho} \hat{\boldsymbol{f}} \boldsymbol{\cdot} \hat{\boldsymbol{u}} \,\text{d} \hat{V} \nonumber\\ &\quad + \frac{1}{2 \hat{\beta}_s} \int_{\partial X} \hat{u}_s^2 \,\text{d}\hat{A} + \hat{\tau}_s \int_{\partial X} \vert \hat{u}_s \vert \,\text{d}\hat{A}. \end{align}

For the augmented Lagrangian approach we require to relax the rate of strain tensor to the auxiliary tensor ![]() $\hat {\boldsymbol {q}}$ and the restriction of the velocity vector on

$\hat {\boldsymbol {q}}$ and the restriction of the velocity vector on ![]() $\partial X$ to the auxiliary vector

$\partial X$ to the auxiliary vector ![]() $\hat {\boldsymbol {\xi }}$. Then the saddle-point problem associated with

$\hat {\boldsymbol {\xi }}$. Then the saddle-point problem associated with ![]() $\mathbb {P}$ is

$\mathbb {P}$ is

\begin{align} \mathcal{J}(\hat{\boldsymbol{u}},\hat{\boldsymbol{q}},\hat{\boldsymbol{\xi}}) & = \frac{\hat{\mu}}{2} \int_{\varOmega \setminus \bar{X}} \hat{\boldsymbol{q}} \boldsymbol{:} \hat{\boldsymbol{q}}\,\text{d}\hat{V} + \hat{\tau}_y \int_{\varOmega \setminus \bar{X}} \Vert \hat{\boldsymbol{q}} \Vert \,\text{d}\hat{V} + \frac{1}{2} \int_{\varOmega \setminus \bar{X}} \left[ \hat{\dot{\boldsymbol{\gamma}}} \left( \hat{\boldsymbol{u}} \right) - \hat{\boldsymbol{q}} \right] \boldsymbol{:} \hat{\boldsymbol{T}} \,\text{d}\hat{V} \nonumber\\ &\quad - \int_{\varOmega \setminus \bar{X}} \hat{\rho} \hat{\boldsymbol{f}} \boldsymbol{\cdot} \hat{\boldsymbol{u}} ~\text{d} \hat{V} + \frac{1}{2 \hat{\beta}_s} \int_{\partial X} \hat{\boldsymbol{\xi}}^2 \,\text{d}\hat{A} + \hat{\tau}_s \int_{\partial X} \vert \hat{\boldsymbol{\xi}} \vert \,\text{d}\hat{A} + \int_{\partial X} \hat{\boldsymbol{\lambda}} \boldsymbol{\cdot} \left( \hat{\boldsymbol{\xi}} - \boldsymbol{\delta} \hat{\boldsymbol{u}} \right) \text{d}\hat{A} \nonumber\\ & \quad + \frac{a \hat{\mu}}{2} \int_{\varOmega \setminus \bar{X}} \left( \hat{\dot{\boldsymbol{\gamma}}} \left( \hat{\boldsymbol{u}} \right) - \hat{\boldsymbol{q}} \right) \boldsymbol{:} \left( \hat{\dot{\boldsymbol{\gamma}}} \left( \hat{\boldsymbol{u}} \right) - \hat{\boldsymbol{q}} \right) \text{d}\hat{V} + \frac{b}{2 \hat{\beta}_s} \int_{\partial X} \left( \hat{\boldsymbol{\xi}} - \boldsymbol{\delta} \hat{\boldsymbol{u}} \right)^2 \text{d}\hat{A}, \end{align}

\begin{align} \mathcal{J}(\hat{\boldsymbol{u}},\hat{\boldsymbol{q}},\hat{\boldsymbol{\xi}}) & = \frac{\hat{\mu}}{2} \int_{\varOmega \setminus \bar{X}} \hat{\boldsymbol{q}} \boldsymbol{:} \hat{\boldsymbol{q}}\,\text{d}\hat{V} + \hat{\tau}_y \int_{\varOmega \setminus \bar{X}} \Vert \hat{\boldsymbol{q}} \Vert \,\text{d}\hat{V} + \frac{1}{2} \int_{\varOmega \setminus \bar{X}} \left[ \hat{\dot{\boldsymbol{\gamma}}} \left( \hat{\boldsymbol{u}} \right) - \hat{\boldsymbol{q}} \right] \boldsymbol{:} \hat{\boldsymbol{T}} \,\text{d}\hat{V} \nonumber\\ &\quad - \int_{\varOmega \setminus \bar{X}} \hat{\rho} \hat{\boldsymbol{f}} \boldsymbol{\cdot} \hat{\boldsymbol{u}} ~\text{d} \hat{V} + \frac{1}{2 \hat{\beta}_s} \int_{\partial X} \hat{\boldsymbol{\xi}}^2 \,\text{d}\hat{A} + \hat{\tau}_s \int_{\partial X} \vert \hat{\boldsymbol{\xi}} \vert \,\text{d}\hat{A} + \int_{\partial X} \hat{\boldsymbol{\lambda}} \boldsymbol{\cdot} \left( \hat{\boldsymbol{\xi}} - \boldsymbol{\delta} \hat{\boldsymbol{u}} \right) \text{d}\hat{A} \nonumber\\ & \quad + \frac{a \hat{\mu}}{2} \int_{\varOmega \setminus \bar{X}} \left( \hat{\dot{\boldsymbol{\gamma}}} \left( \hat{\boldsymbol{u}} \right) - \hat{\boldsymbol{q}} \right) \boldsymbol{:} \left( \hat{\dot{\boldsymbol{\gamma}}} \left( \hat{\boldsymbol{u}} \right) - \hat{\boldsymbol{q}} \right) \text{d}\hat{V} + \frac{b}{2 \hat{\beta}_s} \int_{\partial X} \left( \hat{\boldsymbol{\xi}} - \boldsymbol{\delta} \hat{\boldsymbol{u}} \right)^2 \text{d}\hat{A}, \end{align}

where ![]() $a$ and

$a$ and ![]() $b$ are arbitrary constants (augmentation parameters);

$b$ are arbitrary constants (augmentation parameters); ![]() $\hat {\boldsymbol {T}}$ and

$\hat {\boldsymbol {T}}$ and ![]() $\hat {\boldsymbol {\lambda }}$ are the Lagrange multipliers.

$\hat {\boldsymbol {\lambda }}$ are the Lagrange multipliers.

Hence, the Uzawa algorithm in the presence of slip takes the form of algorithm 1. Upon convergence of algorithm 1 with the free augmentation parameters ![]() $a$ and

$a$ and ![]() $b$, the Lagrange multiplier

$b$, the Lagrange multiplier ![]() $\hat {\boldsymbol {T}}$ converges to the true stress field,

$\hat {\boldsymbol {T}}$ converges to the true stress field, ![]() $\hat {\boldsymbol {q}}$ to the true rate of strain tensor, Lagrange multiplier

$\hat {\boldsymbol {q}}$ to the true rate of strain tensor, Lagrange multiplier ![]() $\hat {\boldsymbol {\lambda }}$ to the traction vector on

$\hat {\boldsymbol {\lambda }}$ to the traction vector on ![]() $\partial X$, and auxiliary variable

$\partial X$, and auxiliary variable ![]() $\hat {\boldsymbol {\xi }}$ to the velocity on

$\hat {\boldsymbol {\xi }}$ to the velocity on ![]() $\partial X$.

$\partial X$.

A mesh adaptation procedure, the same as the one proposed by Roquet & Saramito (Reference Roquet and Saramito2003), could be coupled with the above algorithm to obtain a fine resolution of the yield surfaces. Based on this procedure, the adapted mesh is stretched anisotropically in the direction of the eigenvectors of the Hessian of ![]() $\sqrt {\hat {\mu } \,\hat {\dot {\boldsymbol {\gamma }}} \boldsymbol {:} \hat {\dot {\boldsymbol {\gamma }}} + \hat {\tau }_y \Vert \hat {\dot {\boldsymbol {\gamma }}} \Vert }$, which is the square root of the local energy dissipation. In this study, we implement the entire numerical algorithm in an open-source C

$\sqrt {\hat {\mu } \,\hat {\dot {\boldsymbol {\gamma }}} \boldsymbol {:} \hat {\dot {\boldsymbol {\gamma }}} + \hat {\tau }_y \Vert \hat {\dot {\boldsymbol {\gamma }}} \Vert }$, which is the square root of the local energy dissipation. In this study, we implement the entire numerical algorithm in an open-source C![]() $++$ finite element environment – FreeFEM

$++$ finite element environment – FreeFEM![]() $++$ (Hecht Reference Hecht2012). We have previously validated our numerical implementation and mesh adaptation widely within various studies (Chaparian & Frigaard Reference Chaparian and Frigaard2017b; Chaparian & Tammisola Reference Chaparian and Tammisola2019; Chaparian et al. Reference Chaparian, Izbassarov, De Vita, Brandt and Tammisola2020). Here we will not go into technical details such as the convergence rate, since such details are well-documented in the previous studies – please see, for example, Roquet & Saramito (Reference Roquet and Saramito2008).

$++$ (Hecht Reference Hecht2012). We have previously validated our numerical implementation and mesh adaptation widely within various studies (Chaparian & Frigaard Reference Chaparian and Frigaard2017b; Chaparian & Tammisola Reference Chaparian and Tammisola2019; Chaparian et al. Reference Chaparian, Izbassarov, De Vita, Brandt and Tammisola2020). Here we will not go into technical details such as the convergence rate, since such details are well-documented in the previous studies – please see, for example, Roquet & Saramito (Reference Roquet and Saramito2008).

In what follows, we quickly validate the algorithm for the sliding flows and most importantly derive variational tools (Mosolov & Miasnikov Reference Mosolov and Miasnikov1965) for a sample problem. These tools will be used to analyse more complex flows in the next sections.

3. Benchmark problem: sliding channel Poiseuille flow

In this section we consider the sliding flow of a Bingham fluid in a channel (Poiseuille flow) – the same as the one shown in figure 1. The walls are denoted by ![]() $\varGamma$ and the full domain by

$\varGamma$ and the full domain by ![]() $\varOmega$. We consider two classic formulations: (i) the mobility problem ([M]) where the pressure gradient is applied and the flow rate can be computed and (ii) the resistance problem ([R]) in which flow rate is set and as a result pressure gradient can be computed. We also validate the presented numerical algorithm and derive/revisit some variational tools (Huilgol Reference Huilgol1998) useful for the rest of this study.

$\varOmega$. We consider two classic formulations: (i) the mobility problem ([M]) where the pressure gradient is applied and the flow rate can be computed and (ii) the resistance problem ([R]) in which flow rate is set and as a result pressure gradient can be computed. We also validate the presented numerical algorithm and derive/revisit some variational tools (Huilgol Reference Huilgol1998) useful for the rest of this study.

3.1. The [M] problem

In this subsection, we use ![]() $\hat {G} \hat {H}^2 /\hat {\mu }$ as the velocity scale,

$\hat {G} \hat {H}^2 /\hat {\mu }$ as the velocity scale, ![]() $\hat {G}\hat {H}$ as the characteristic viscous stress to scale the deviatoric stress tensor and

$\hat {G}\hat {H}$ as the characteristic viscous stress to scale the deviatoric stress tensor and ![]() $\hat {H} / \hat {\mu }$ to scale the slip coefficient where

$\hat {H} / \hat {\mu }$ to scale the slip coefficient where ![]() $\hat {G}$ is the absolute value of the applied pressure-gradient to drive the flow from left to right (in the positive direction of the

$\hat {G}$ is the absolute value of the applied pressure-gradient to drive the flow from left to right (in the positive direction of the ![]() $x$-axis). Hence, the non-dimensional governing and constitutive equations take the forms

$x$-axis). Hence, the non-dimensional governing and constitutive equations take the forms

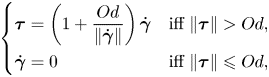

and

\begin{equation} \left\{ \begin{array}{@{}ll} \boldsymbol{\tau} = \left( 1 + \displaystyle{\dfrac{Od}{\Vert\dot{\boldsymbol{\gamma}}\Vert}} \right) \dot{\boldsymbol{\gamma}} & \mbox{iff}\ \Vert \boldsymbol{\tau} \Vert > Od, \\ \dot{\boldsymbol{\gamma}} = 0 & \mbox{iff}\ \Vert \boldsymbol{\tau} \Vert \leqslant Od, \end{array} \right. \end{equation}

\begin{equation} \left\{ \begin{array}{@{}ll} \boldsymbol{\tau} = \left( 1 + \displaystyle{\dfrac{Od}{\Vert\dot{\boldsymbol{\gamma}}\Vert}} \right) \dot{\boldsymbol{\gamma}} & \mbox{iff}\ \Vert \boldsymbol{\tau} \Vert > Od, \\ \dot{\boldsymbol{\gamma}} = 0 & \mbox{iff}\ \Vert \boldsymbol{\tau} \Vert \leqslant Od, \end{array} \right. \end{equation}respectively, and the slip law

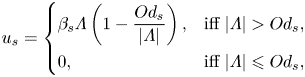

\begin{equation} u_{s} = \left\{ \begin{array}{@{}ll} \beta_s \varLambda \left( 1 - \displaystyle\dfrac{Od_s}{\vert \varLambda \vert} \right), & \text{iff}\ \vert \varLambda \vert > Od_s, \\ 0, & \text{iff}\ \vert \varLambda \vert \leqslant Od_s, \end{array} \right. \end{equation}

\begin{equation} u_{s} = \left\{ \begin{array}{@{}ll} \beta_s \varLambda \left( 1 - \displaystyle\dfrac{Od_s}{\vert \varLambda \vert} \right), & \text{iff}\ \vert \varLambda \vert > Od_s, \\ 0, & \text{iff}\ \vert \varLambda \vert \leqslant Od_s, \end{array} \right. \end{equation}

where ![]() $Od = {\hat {\tau }_y}/{\hat {H} \hat {G}}$ and

$Od = {\hat {\tau }_y}/{\hat {H} \hat {G}}$ and ![]() $Od_s = {\hat {\tau }_s}/{\hat {H} \hat {G}}$. In what follows, the ratio

$Od_s = {\hat {\tau }_s}/{\hat {H} \hat {G}}$. In what follows, the ratio ![]() ${\hat {\tau }_s}/{\hat {\tau }_y}$ is denoted by

${\hat {\tau }_s}/{\hat {\tau }_y}$ is denoted by ![]() $\alpha _s$. The analytical solutions to the velocity and stress fields are derived in appendix A.1.

$\alpha _s$. The analytical solutions to the velocity and stress fields are derived in appendix A.1.

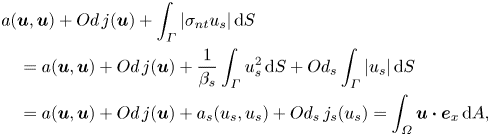

The energy balance equation in the presence of slip is

\begin{align} & a(\boldsymbol{u},\boldsymbol{u}) + Od \,j(\boldsymbol{u}) + \int_{\varGamma} \vert \sigma_{nt} u_s \vert \,\text{d}S \nonumber\\ &\quad = a(\boldsymbol{u},\boldsymbol{u}) + Od \,j(\boldsymbol{u}) + \frac{1}{\beta_s} \int_{\varGamma} u^2_s \,\text{d}S + Od_s \int_{\varGamma} \vert u_s \vert \,\text{d}S \nonumber\\ & \quad = a(\boldsymbol{u},\boldsymbol{u}) + Od \,j(\boldsymbol{u}) + a_s (u_s,u_s) + Od_s \,j_s(u_s) = \int_{\varOmega} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A, \end{align}

\begin{align} & a(\boldsymbol{u},\boldsymbol{u}) + Od \,j(\boldsymbol{u}) + \int_{\varGamma} \vert \sigma_{nt} u_s \vert \,\text{d}S \nonumber\\ &\quad = a(\boldsymbol{u},\boldsymbol{u}) + Od \,j(\boldsymbol{u}) + \frac{1}{\beta_s} \int_{\varGamma} u^2_s \,\text{d}S + Od_s \int_{\varGamma} \vert u_s \vert \,\text{d}S \nonumber\\ & \quad = a(\boldsymbol{u},\boldsymbol{u}) + Od \,j(\boldsymbol{u}) + a_s (u_s,u_s) + Od_s \,j_s(u_s) = \int_{\varOmega} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A, \end{align}

where ![]() $a(\boldsymbol {u},\boldsymbol {u}) = \int _{\varOmega } \dot {\boldsymbol {\gamma }} (\boldsymbol {u}) \boldsymbol {:} \dot {\boldsymbol {\gamma }} (\boldsymbol {u}) \,\text {d} A$ and

$a(\boldsymbol {u},\boldsymbol {u}) = \int _{\varOmega } \dot {\boldsymbol {\gamma }} (\boldsymbol {u}) \boldsymbol {:} \dot {\boldsymbol {\gamma }} (\boldsymbol {u}) \,\text {d} A$ and ![]() $Od\,j(\boldsymbol {u}) = Od\int _{\varOmega } \Vert \dot {\boldsymbol {\gamma }} (\boldsymbol {u}) \Vert \,\text {d} A$ are the viscous and plastic dissipations, respectively. Please note that the slip dissipation

$Od\,j(\boldsymbol {u}) = Od\int _{\varOmega } \Vert \dot {\boldsymbol {\gamma }} (\boldsymbol {u}) \Vert \,\text {d} A$ are the viscous and plastic dissipations, respectively. Please note that the slip dissipation ![]() $\int _{\partial X} \vert \sigma _{nt} u_s \vert \,\text {d}S$ can be split into two terms: the ‘viscous’ slip dissipation

$\int _{\partial X} \vert \sigma _{nt} u_s \vert \,\text {d}S$ can be split into two terms: the ‘viscous’ slip dissipation ![]() $(1/\beta _s) \int _{\varGamma } u_s^2\,\text {d}S$ which is designated by

$(1/\beta _s) \int _{\varGamma } u_s^2\,\text {d}S$ which is designated by ![]() $a_s (u_s,u_s)$ in this study and the ‘plastic’ slip dissipation

$a_s (u_s,u_s)$ in this study and the ‘plastic’ slip dissipation ![]() $Od_s \int _{\varGamma } \vert u_s \vert \,\text {d}S$ with

$Od_s \int _{\varGamma } \vert u_s \vert \,\text {d}S$ with ![]() $Od_s ~j_s(u_s)$. Moreover,

$Od_s ~j_s(u_s)$. Moreover, ![]() $j(\boldsymbol {u})$ is the normalized plastic dissipation and

$j(\boldsymbol {u})$ is the normalized plastic dissipation and ![]() $j_s(u_s)$ the normalized ‘plastic’ slip dissipation.

$j_s(u_s)$ the normalized ‘plastic’ slip dissipation.

We can rearrange the energy balance equation and form a set of inequalities as follows:

\begin{align} 0 \leqslant a(\boldsymbol{u},\boldsymbol{u}) &= -j(\boldsymbol{u}) \left( Od - \frac{\displaystyle \int_{\varOmega} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - a_s (u_s,u_s) - Od_s j_s (u_s)}{j(\boldsymbol{u})} \right) \nonumber\\ &\leqslant -j(\boldsymbol{u}) \left( Od - \frac{\displaystyle \int_{\varOmega} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - Od_s j_s (u_s)}{j(\boldsymbol{u})} \right) \nonumber\\ &\leqslant -j(\boldsymbol{u}) \left( Od - \sup_{\boldsymbol{v} \in \boldsymbol{V}, \boldsymbol{v} \neq \boldsymbol{0}} \frac{\displaystyle \int_{\varOmega} \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - Od_s j_s (v_s)}{j(\boldsymbol{v})} \right), \end{align}

\begin{align} 0 \leqslant a(\boldsymbol{u},\boldsymbol{u}) &= -j(\boldsymbol{u}) \left( Od - \frac{\displaystyle \int_{\varOmega} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - a_s (u_s,u_s) - Od_s j_s (u_s)}{j(\boldsymbol{u})} \right) \nonumber\\ &\leqslant -j(\boldsymbol{u}) \left( Od - \frac{\displaystyle \int_{\varOmega} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - Od_s j_s (u_s)}{j(\boldsymbol{u})} \right) \nonumber\\ &\leqslant -j(\boldsymbol{u}) \left( Od - \sup_{\boldsymbol{v} \in \boldsymbol{V}, \boldsymbol{v} \neq \boldsymbol{0}} \frac{\displaystyle \int_{\varOmega} \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - Od_s j_s (v_s)}{j(\boldsymbol{v})} \right), \end{align}to find the definition of the critical Oldroyd number in the presence of slip as

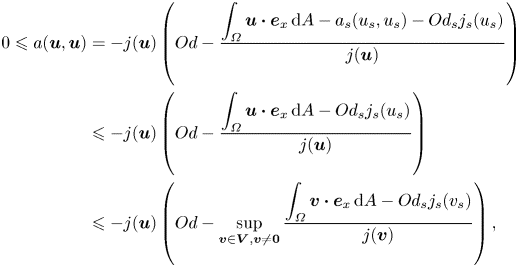

\begin{equation} Od_c = \sup_{\boldsymbol{v} \in \boldsymbol{V}, \boldsymbol{v} \neq \boldsymbol{0}} \left( \frac{\displaystyle \int_{\varOmega} \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - Od_s j_s (v_s)}{j(\boldsymbol{v})} \right), \end{equation}

\begin{equation} Od_c = \sup_{\boldsymbol{v} \in \boldsymbol{V}, \boldsymbol{v} \neq \boldsymbol{0}} \left( \frac{\displaystyle \int_{\varOmega} \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A - Od_s j_s (v_s)}{j(\boldsymbol{v})} \right), \end{equation}

where ![]() $\boldsymbol {v}$ is a velocity test function from the set of all admissible velocity fields

$\boldsymbol {v}$ is a velocity test function from the set of all admissible velocity fields ![]() $\boldsymbol {V}$. Then it enforces that for

$\boldsymbol {V}$. Then it enforces that for ![]() $Od_c \leqslant Od$,

$Od_c \leqslant Od$, ![]() $a(\boldsymbol {u},\boldsymbol {u})=0$ or

$a(\boldsymbol {u},\boldsymbol {u})=0$ or ![]() $\boldsymbol {u}=0$ (i.e. no flow condition).

$\boldsymbol {u}=0$ (i.e. no flow condition).

We may use (3.6) for calculating ![]() $Od_c$ in simple flows such as Poiseuille flow here: the flow can be postulated by two boundary layers with thickness

$Od_c$ in simple flows such as Poiseuille flow here: the flow can be postulated by two boundary layers with thickness ![]() $\delta$ attached to the walls, through which the slip velocity

$\delta$ attached to the walls, through which the slip velocity ![]() $U_1$ is connected to the plug velocity

$U_1$ is connected to the plug velocity ![]() $U_2$, then,

$U_2$, then,

where ![]() $\ell$ is the length of the chosen control volume. This suggests,

$\ell$ is the length of the chosen control volume. This suggests,

or,

The maximal value of the argument is ![]() $1/2\alpha _s$ which occurs at

$1/2\alpha _s$ which occurs at ![]() $U_1 / U_2 = 1$. Its physical interpretation is that the supremum occurs in the fully sliding regime, which is intuitive. Hence,

$U_1 / U_2 = 1$. Its physical interpretation is that the supremum occurs in the fully sliding regime, which is intuitive. Hence, ![]() $Od_c = 1/2\alpha _s$, or in other words, there is no flow if

$Od_c = 1/2\alpha _s$, or in other words, there is no flow if ![]() $1/2 \leqslant Od_s$, which is in agreement with the solution of the full equations derived in appendix A.1.

$1/2 \leqslant Od_s$, which is in agreement with the solution of the full equations derived in appendix A.1.

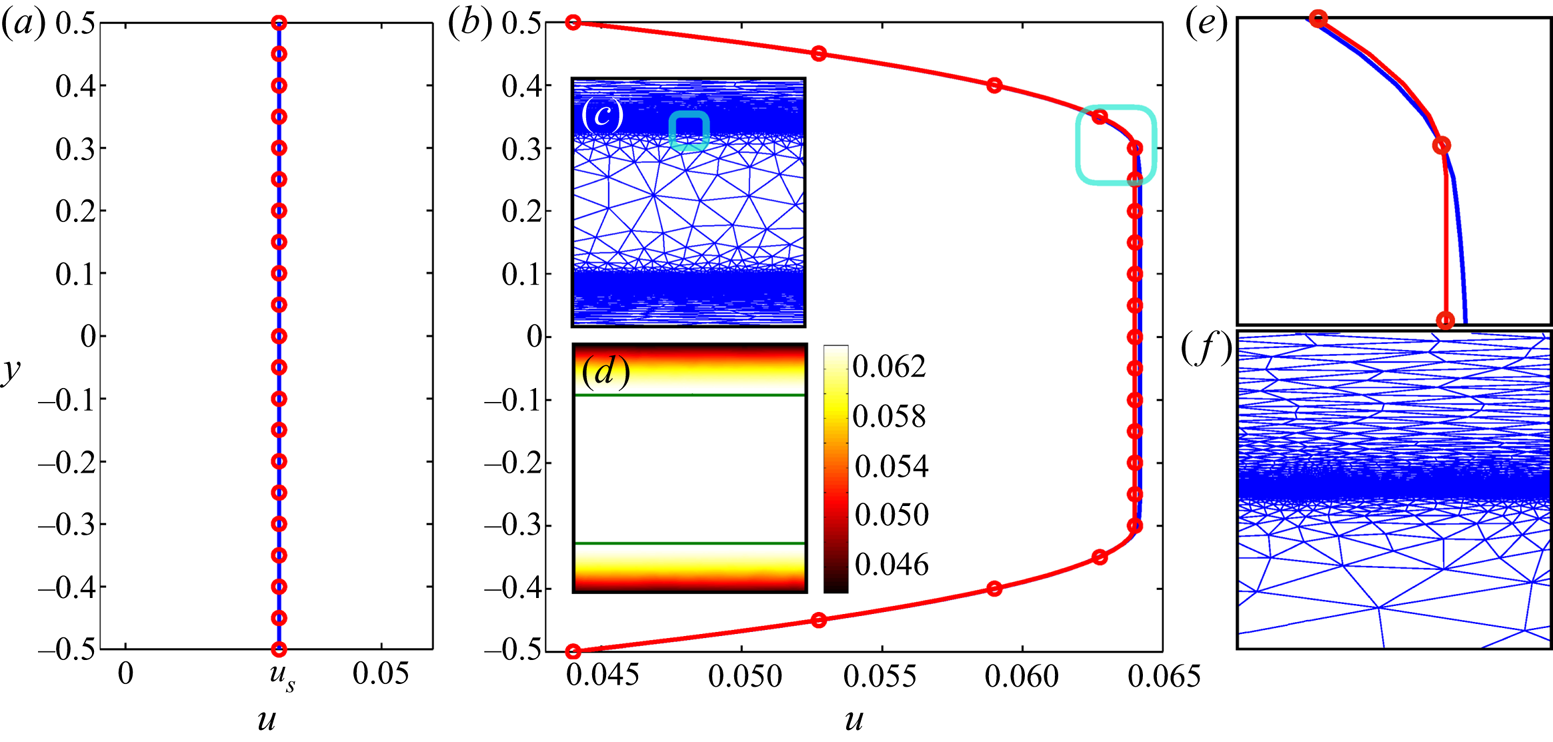

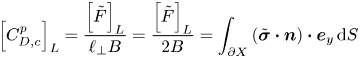

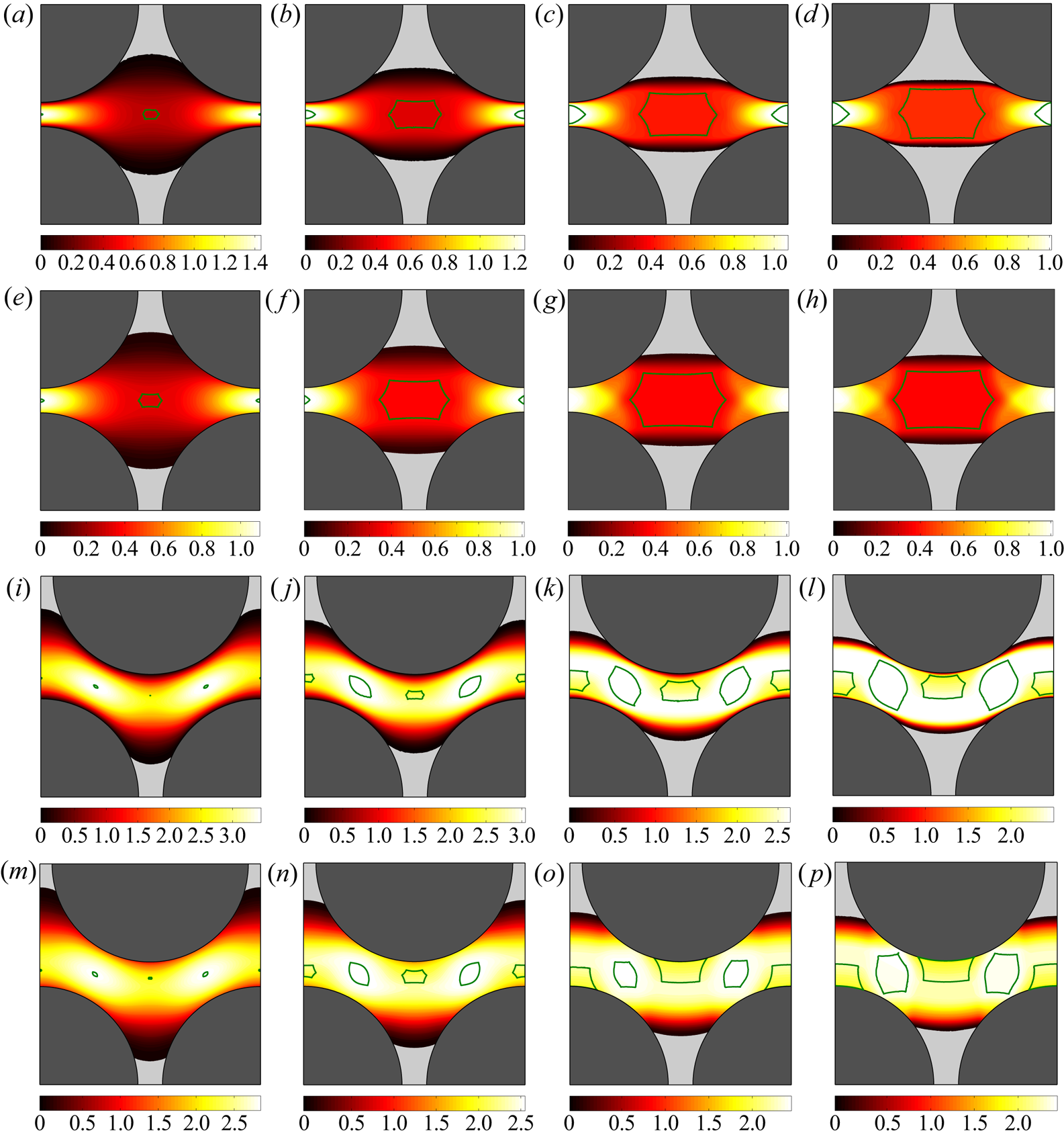

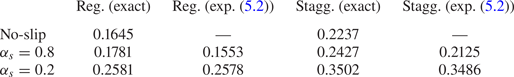

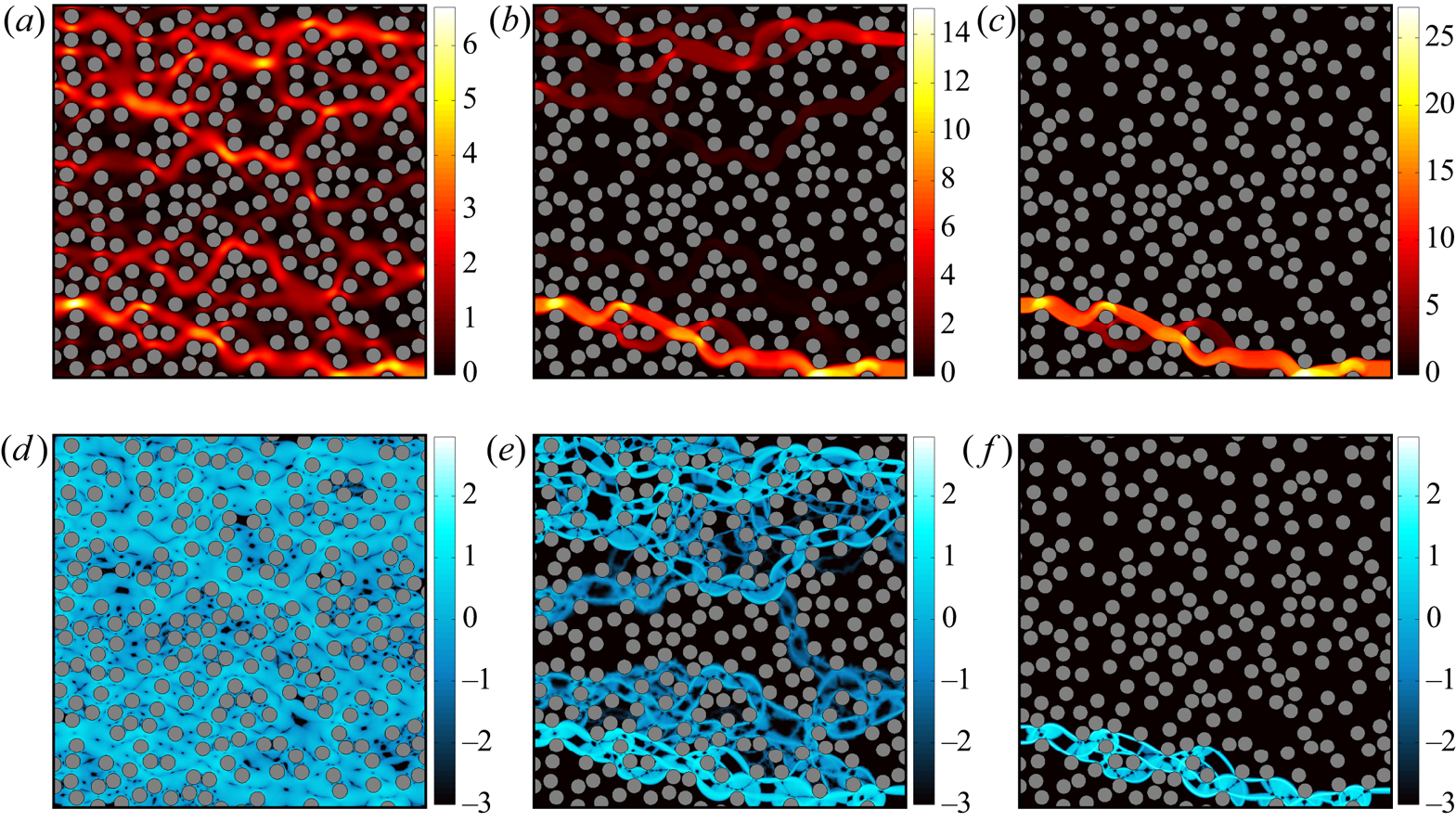

We perform a few simulations for the [M] problem to benchmark the presented algorithm. Figure 3 illustrates different regimes: figure 3(a) compares the computed velocity profile (blue line) in the gap with the analytical solution (red circles) in the fully sliding plug regime (![]() $Od=1, \alpha _s=0.2\ \&\ \beta _s=0.1$) and figure 3(b) within the deforming regime. Utilizing the mesh adaptation seems more indispensable in the deforming regime compared with the fully sliding plug regime, where velocity gradient is zero. It is clear that the velocity distribution after adaptation (red line) is much closer to the analytical solution (red circles) than the solution of the initial mesh (blue line), and also yields a fine resolution of the yield surfaces – see figure 3(d). We shall mention that the focus of the present study is not on quantifying these improvements by the mesh adaptation, as it has been previously studied in detail (Roquet & Saramito Reference Roquet and Saramito2003, Reference Roquet and Saramito2008; Chaparian & Tammisola Reference Chaparian and Tammisola2019).

$Od=1, \alpha _s=0.2\ \&\ \beta _s=0.1$) and figure 3(b) within the deforming regime. Utilizing the mesh adaptation seems more indispensable in the deforming regime compared with the fully sliding plug regime, where velocity gradient is zero. It is clear that the velocity distribution after adaptation (red line) is much closer to the analytical solution (red circles) than the solution of the initial mesh (blue line), and also yields a fine resolution of the yield surfaces – see figure 3(d). We shall mention that the focus of the present study is not on quantifying these improvements by the mesh adaptation, as it has been previously studied in detail (Roquet & Saramito Reference Roquet and Saramito2003, Reference Roquet and Saramito2008; Chaparian & Tammisola Reference Chaparian and Tammisola2019).

Figure 3. The [M] problem features: (a) velocity profile of the case ![]() $Od=1, \alpha _s=0.2, \beta _s=0.1$ (fully sliding plug); (b) velocity profile of the case

$Od=1, \alpha _s=0.2, \beta _s=0.1$ (fully sliding plug); (b) velocity profile of the case ![]() $Od=0.3, \alpha _s=0.2, \beta _s=0.1$ (deforming regime); (c) the mesh after five cycles of adaptation associated with panel (b); (d) velocity contour associated with panel (b), the green lines show the yield surfaces; (e,f) close-up of the cyan windows in the panels (b,c), respectively. Please note that in panels (a,b,e) the blue line shows the numerical data corresponding to the initial mesh, the red line corresponds to the adapted mesh (the mesh shown in the panel (c)) and the red circles are the analytical solution; see appendix A.1.

$Od=0.3, \alpha _s=0.2, \beta _s=0.1$ (deforming regime); (c) the mesh after five cycles of adaptation associated with panel (b); (d) velocity contour associated with panel (b), the green lines show the yield surfaces; (e,f) close-up of the cyan windows in the panels (b,c), respectively. Please note that in panels (a,b,e) the blue line shows the numerical data corresponding to the initial mesh, the red line corresponds to the adapted mesh (the mesh shown in the panel (c)) and the red circles are the analytical solution; see appendix A.1.

3.2. The [R] problem

Here, we reformulate the problem in the resistance scalings and the quantities are designated with asterisk sign (![]() $*$) to prevent any potential confusion with the [M] problem. In the resistance formulation, the velocity is scaled with the mean bulk velocity,

$*$) to prevent any potential confusion with the [M] problem. In the resistance formulation, the velocity is scaled with the mean bulk velocity, ![]() $\hat {U}=\hat {Q}/\hat {H}$, and as a result, there is always a non-zero flow with the flow rate equal to unity (

$\hat {U}=\hat {Q}/\hat {H}$, and as a result, there is always a non-zero flow with the flow rate equal to unity (![]() $Q^*=1$), whether the flow is in the deforming regime or the fully sliding plug regime. The deviatoric stress and pressure are scaled with the characteristic viscous stress,

$Q^*=1$), whether the flow is in the deforming regime or the fully sliding plug regime. The deviatoric stress and pressure are scaled with the characteristic viscous stress, ![]() $\hat {\mu } \hat {U}/\hat {H}$, hence,

$\hat {\mu } \hat {U}/\hat {H}$, hence,

and

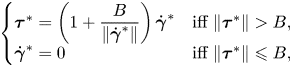

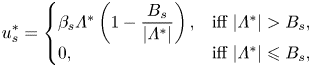

\begin{equation} \left\{ \begin{array}{@{}ll} \boldsymbol{\tau}^* = \left( 1 + \displaystyle{\dfrac{B}{\Vert\dot{\boldsymbol{\gamma}}^*\Vert}} \right) \dot{\boldsymbol{\gamma}}^* & \mbox{iff}\ \Vert \boldsymbol{\tau}^* \Vert > B, \\ \dot{\boldsymbol{\gamma}}^* = 0 & \mbox{iff}\ \Vert \boldsymbol{\tau}^* \Vert \leqslant B, \end{array} \right. \end{equation}

\begin{equation} \left\{ \begin{array}{@{}ll} \boldsymbol{\tau}^* = \left( 1 + \displaystyle{\dfrac{B}{\Vert\dot{\boldsymbol{\gamma}}^*\Vert}} \right) \dot{\boldsymbol{\gamma}}^* & \mbox{iff}\ \Vert \boldsymbol{\tau}^* \Vert > B, \\ \dot{\boldsymbol{\gamma}}^* = 0 & \mbox{iff}\ \Vert \boldsymbol{\tau}^* \Vert \leqslant B, \end{array} \right. \end{equation}with the boundary condition,

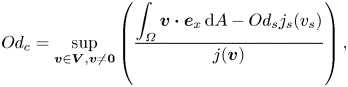

\begin{equation} u^*_{{s}} = \left\{\begin{array}{@{}ll} \beta_s \varLambda^* \left( 1 - \displaystyle\dfrac{B_{s}}{\vert \varLambda^* \vert} \right), & \text{iff}\ \vert \varLambda^* \vert > B_{s}, \\ 0, & \text{iff}\ \vert \varLambda^* \vert \leqslant B_{s}, \end{array} \right. \end{equation}

\begin{equation} u^*_{{s}} = \left\{\begin{array}{@{}ll} \beta_s \varLambda^* \left( 1 - \displaystyle\dfrac{B_{s}}{\vert \varLambda^* \vert} \right), & \text{iff}\ \vert \varLambda^* \vert > B_{s}, \\ 0, & \text{iff}\ \vert \varLambda^* \vert \leqslant B_{s}, \end{array} \right. \end{equation}

on the walls govern the [R] problem. Please note that ![]() $G^*$ is the absolute value of the pressure gradient which enforces the unity flow rate for a given Bingham number

$G^*$ is the absolute value of the pressure gradient which enforces the unity flow rate for a given Bingham number ![]() $( {\hat {\tau }_y \hat {H}}/{\hat {\mu } \hat {U}} )$,

$( {\hat {\tau }_y \hat {H}}/{\hat {\mu } \hat {U}} )$, ![]() $\alpha _s$ and

$\alpha _s$ and ![]() $\beta _s$. The energy balance equation in this case is

$\beta _s$. The energy balance equation in this case is

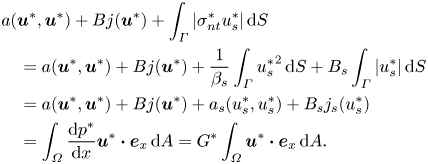

\begin{align} & a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + \int_{\varGamma} \vert \sigma^*_{nt} u^*_s \vert \, \text{d}S \nonumber\\ &\quad = a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + \frac{1}{\beta_s} \int_{\varGamma} {u^*_s}^2 \,\text{d}S + B_s \int_{\varGamma} \vert u^*_s \vert \,\text{d}S \nonumber\\ & \quad = a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + a_s (u^*_s,u^*_s) + B_s j_s (u^*_s) \nonumber\\ &\quad = \int_{\varOmega} \frac{\text{d} p^*}{\text{d} x} \boldsymbol{u}^* \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A = G^* \int_{\varOmega} \boldsymbol{u}^* \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A. \end{align}

\begin{align} & a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + \int_{\varGamma} \vert \sigma^*_{nt} u^*_s \vert \, \text{d}S \nonumber\\ &\quad = a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + \frac{1}{\beta_s} \int_{\varGamma} {u^*_s}^2 \,\text{d}S + B_s \int_{\varGamma} \vert u^*_s \vert \,\text{d}S \nonumber\\ & \quad = a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + a_s (u^*_s,u^*_s) + B_s j_s (u^*_s) \nonumber\\ &\quad = \int_{\varOmega} \frac{\text{d} p^*}{\text{d} x} \boldsymbol{u}^* \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A = G^* \int_{\varOmega} \boldsymbol{u}^* \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A. \end{align} Frigaard (Reference Frigaard2019) has shown that at the yield limit (![]() $B \to \infty$), viscous dissipation is at least one order of magnitude less than the plastic dissipation (when

$B \to \infty$), viscous dissipation is at least one order of magnitude less than the plastic dissipation (when ![]() $B \to \infty$:

$B \to \infty$: ![]() $a(\boldsymbol {u}^*,\boldsymbol {u}^*) \ll B j(\boldsymbol {u}^*)$). With a little extra effort, we can show that this applies to

$a(\boldsymbol {u}^*,\boldsymbol {u}^*) \ll B j(\boldsymbol {u}^*)$). With a little extra effort, we can show that this applies to ![]() $a_s (u^*_s,u^*_s)$ and

$a_s (u^*_s,u^*_s)$ and ![]() $B_s j_s (u^*_s)$ as well, knowing that

$B_s j_s (u^*_s)$ as well, knowing that ![]() $u_s^* \leqslant 1$ (from the continuity equation

$u_s^* \leqslant 1$ (from the continuity equation ![]() $Q^*=1$) and

$Q^*=1$) and ![]() $B_s \to \infty$ in this limit. Exploiting that generally the mapping between [M] and [R] problems is attainable via

$B_s \to \infty$ in this limit. Exploiting that generally the mapping between [M] and [R] problems is attainable via ![]() $Q = {Od}/{B}$ or

$Q = {Od}/{B}$ or ![]() $G^* = {B}/{Od}$, one can extract the critical Oldroyd number from the [R] formulation through

$G^* = {B}/{Od}$, one can extract the critical Oldroyd number from the [R] formulation through

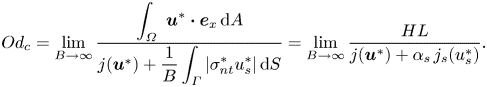

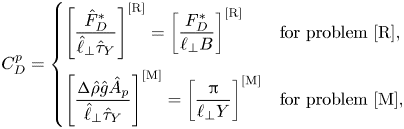

\begin{equation} Od_c = \lim_{B \to \infty} \frac{\displaystyle \int_{\varOmega} ~ \boldsymbol{u}^* \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A}{j(\boldsymbol{u}^*)+\displaystyle \frac{1}{B} \int_{\varGamma} \vert \sigma^*_{nt} u^*_s \vert \,\text{d}S} = \displaystyle \lim_{B \to \infty} \frac{HL}{j(\boldsymbol{u}^*)+\alpha_s \,j_s (u^*_s)}. \end{equation}

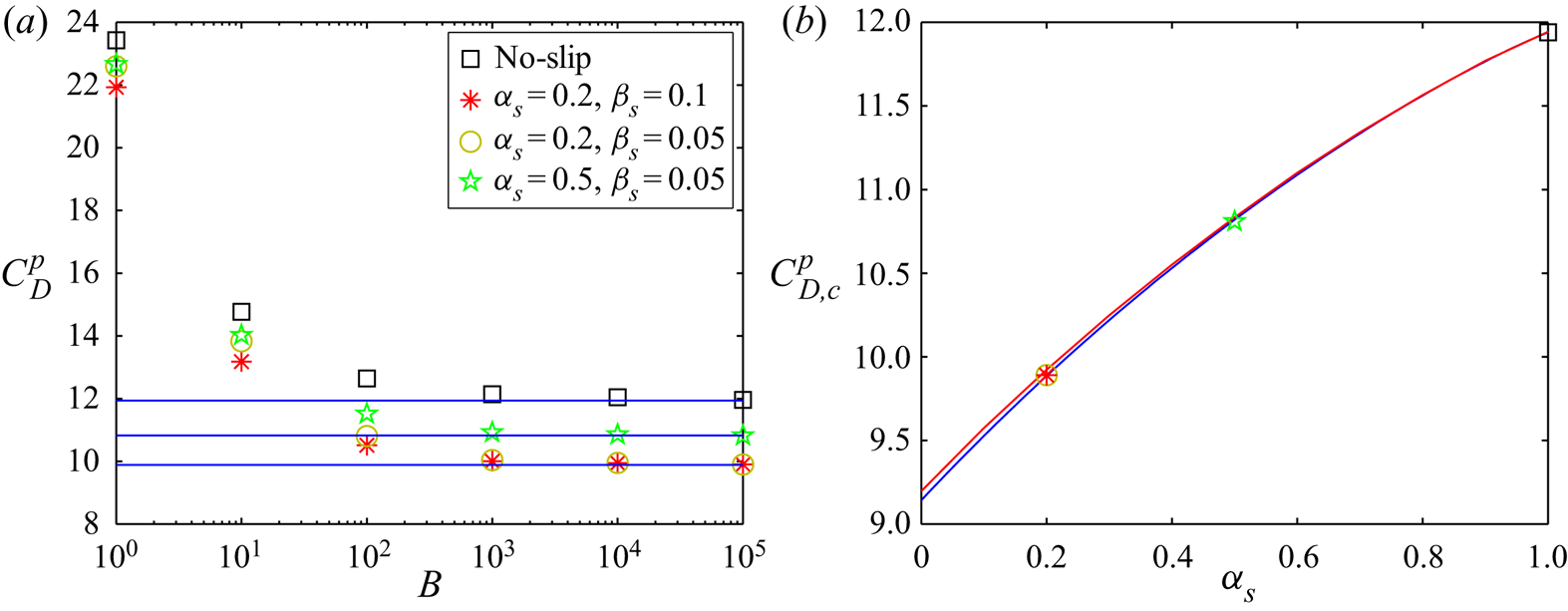

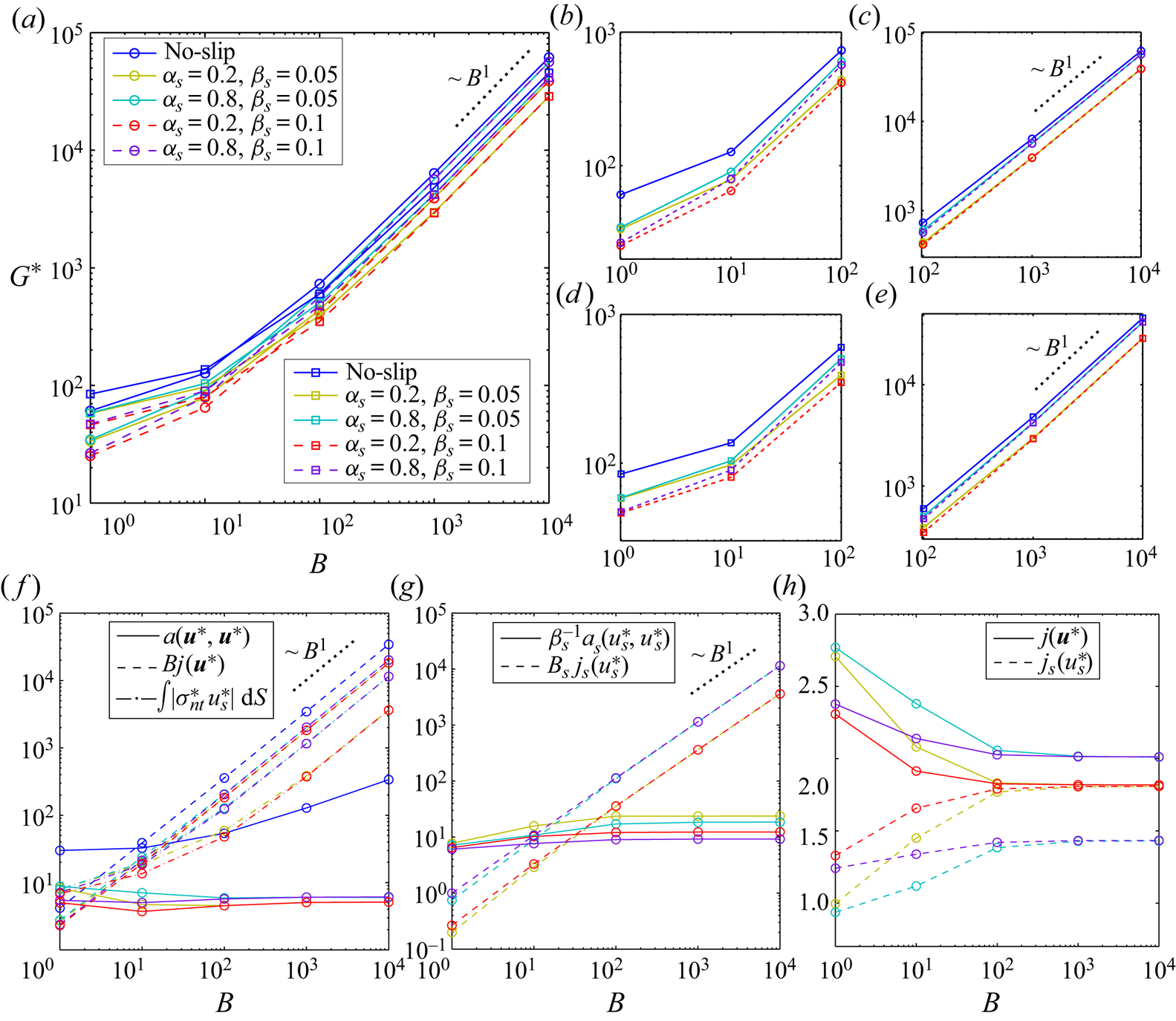

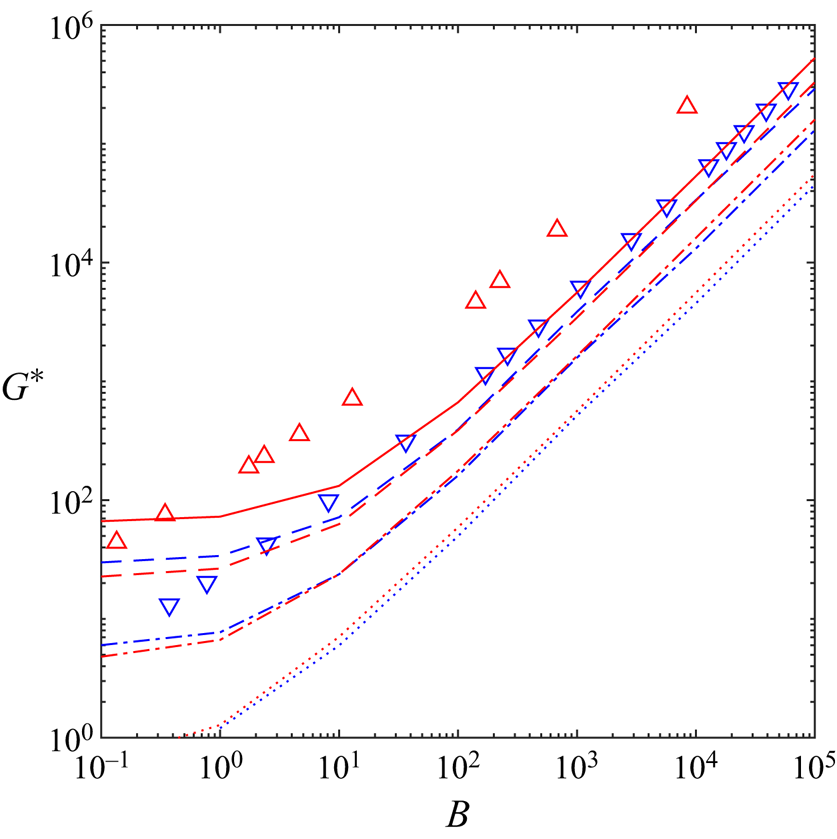

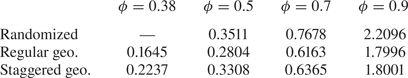

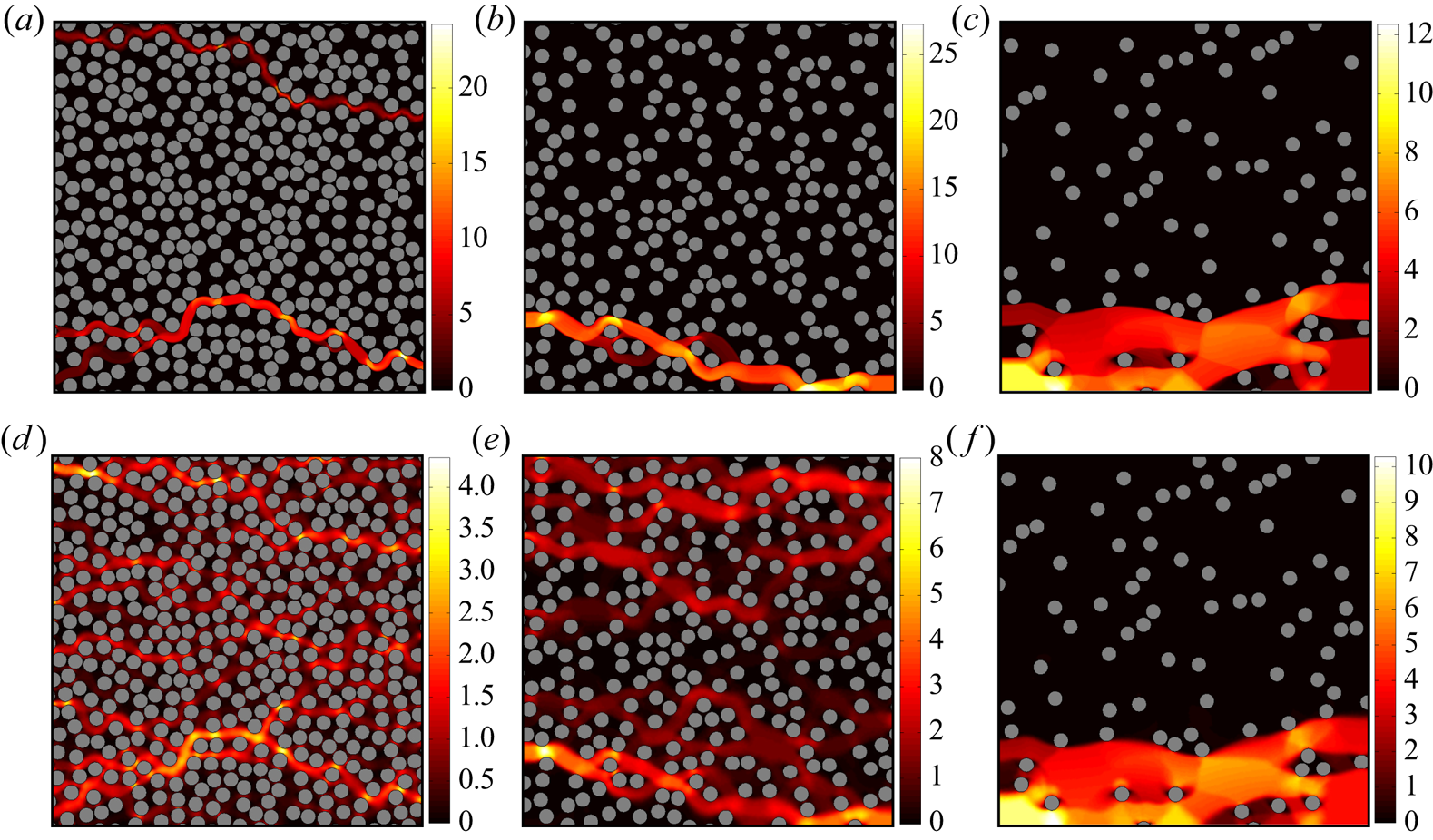

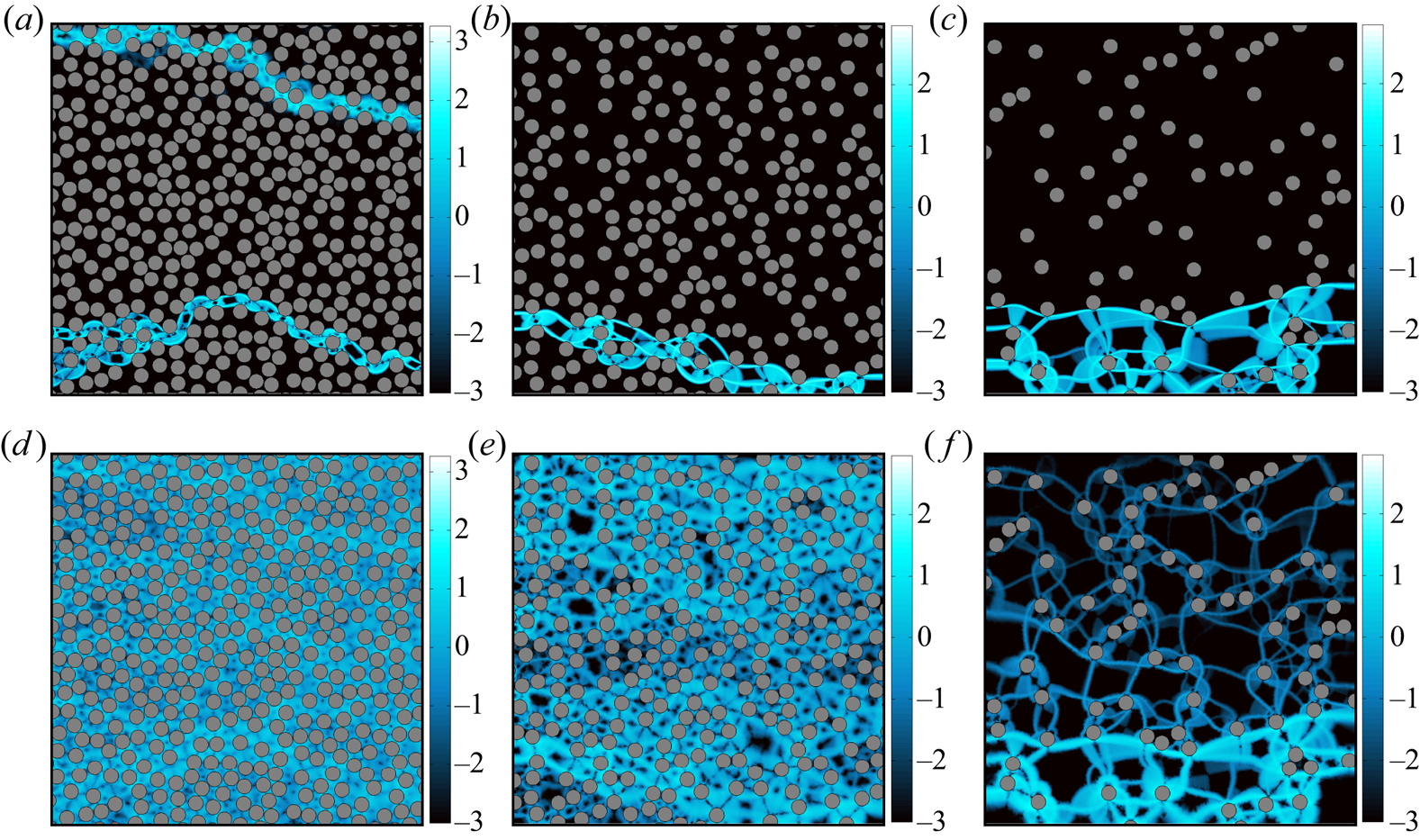

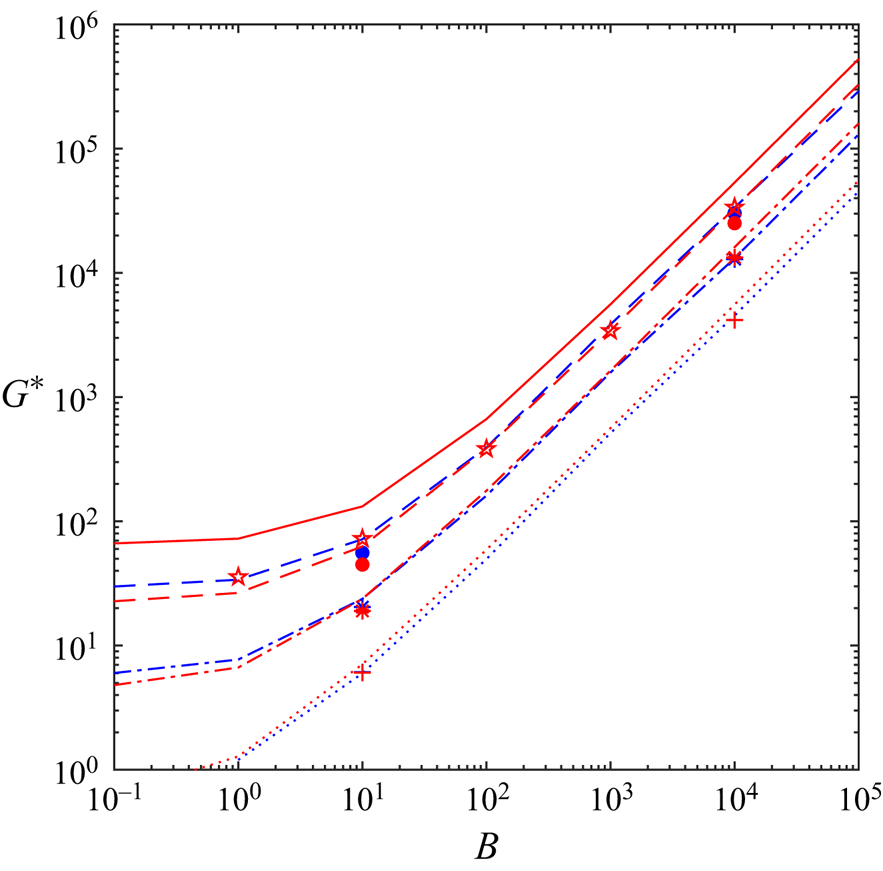

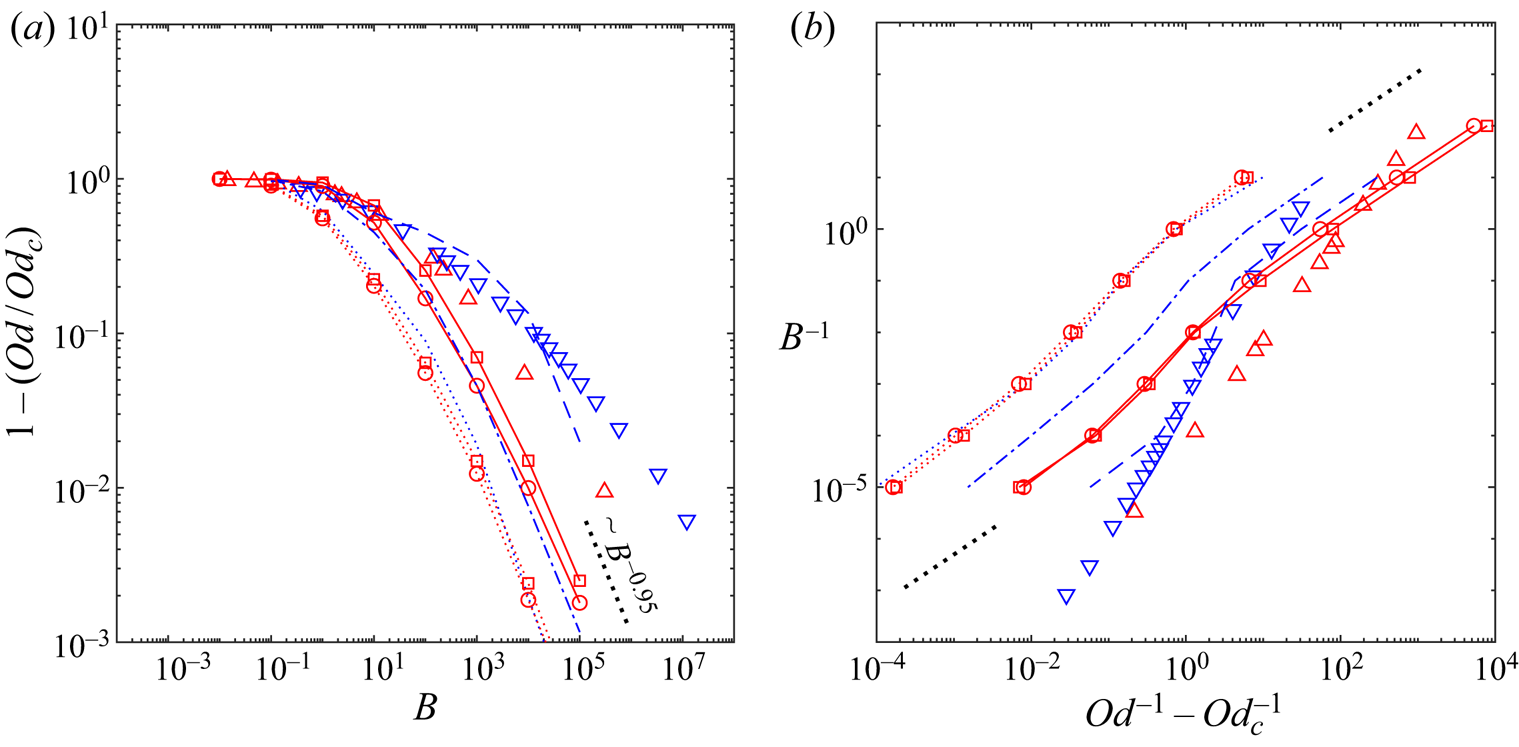

\begin{equation} Od_c = \lim_{B \to \infty} \frac{\displaystyle \int_{\varOmega} ~ \boldsymbol{u}^* \boldsymbol{\cdot} \boldsymbol{e}_x \,\text{d}A}{j(\boldsymbol{u}^*)+\displaystyle \frac{1}{B} \int_{\varGamma} \vert \sigma^*_{nt} u^*_s \vert \,\text{d}S} = \displaystyle \lim_{B \to \infty} \frac{HL}{j(\boldsymbol{u}^*)+\alpha_s \,j_s (u^*_s)}. \end{equation} To explain the relation between [R] and [M] problems further, we consider some examples in figure 4. The analytical solutions to (3.10)–(3.12) of the [R] problem are derived in appendix A.2. The absolute value of the pressure gradient versus the Bingham number under the no-slip condition and the sliding flow ![]() $\alpha _s=0.2\ \&\ \beta _s=0.1$ are shown with the continuous black and red lines, respectively. While for both type of flows an increase in

$\alpha _s=0.2\ \&\ \beta _s=0.1$ are shown with the continuous black and red lines, respectively. While for both type of flows an increase in ![]() $G^*$ by increasing Bingham number can be observed, they display different trends. This can be explained by knowing that beyond a critical Bingham number (

$G^*$ by increasing Bingham number can be observed, they display different trends. This can be explained by knowing that beyond a critical Bingham number (![]() $\bar {B} = 1/\beta _s (1-\alpha _s) \leqslant B$), the sliding flow state switches from the deforming regime to the fully sliding plug regime. Only at large enough Bingham numbers (

$\bar {B} = 1/\beta _s (1-\alpha _s) \leqslant B$), the sliding flow state switches from the deforming regime to the fully sliding plug regime. Only at large enough Bingham numbers (![]() $B \to \infty$), we can use the numerical data to extract the yield limit. This is illustrated in figure 4 by the dotted lines, where at

$B \to \infty$), we can use the numerical data to extract the yield limit. This is illustrated in figure 4 by the dotted lines, where at ![]() $B \to \infty$,

$B \to \infty$, ![]() $G^*$ asymptotes to

$G^*$ asymptotes to ![]() $2B$ and

$2B$ and ![]() $2 \alpha _s B = 0.4 B$ for no-slip and the sample sliding flow considered, respectively. In this limit,

$2 \alpha _s B = 0.4 B$ for no-slip and the sample sliding flow considered, respectively. In this limit, ![]() $j(\boldsymbol {u}^*)$ (dashed lines in figure 4) asymptotes to 2 and 0 for the no-slip and sliding flows: this is equivalent to

$j(\boldsymbol {u}^*)$ (dashed lines in figure 4) asymptotes to 2 and 0 for the no-slip and sliding flows: this is equivalent to ![]() $Od_c = 1/2$ and

$Od_c = 1/2$ and ![]() $1/2 \alpha_s$, respectively, knowing that

$1/2 \alpha_s$, respectively, knowing that ![]() $j_s (u_s)$ asymptotes to 2 for the sliding flows at sufficiently large Bingham numbers (follow the red dashed-dotted line in figure 4). These results are the same as the ones derived in appendix A.1 considering the [M] formulation. Please note that due to the log–log scaling used in figure 4,

$j_s (u_s)$ asymptotes to 2 for the sliding flows at sufficiently large Bingham numbers (follow the red dashed-dotted line in figure 4). These results are the same as the ones derived in appendix A.1 considering the [M] formulation. Please note that due to the log–log scaling used in figure 4, ![]() $j(\boldsymbol {u}^*)$ corresponds to the sliding flow, which is exactly equal to zero for

$j(\boldsymbol {u}^*)$ corresponds to the sliding flow, which is exactly equal to zero for ![]() $\bar {B} \leqslant B$ is not visible; however, its fast decay is clear:

$\bar {B} \leqslant B$ is not visible; however, its fast decay is clear: ![]() $j(\boldsymbol {u}^*)$ is almost equal to

$j(\boldsymbol {u}^*)$ is almost equal to ![]() $10^{-2}$ for

$10^{-2}$ for ![]() $B\approx 11.85$ where

$B\approx 11.85$ where ![]() $\bar {B}(\alpha _s=0.2\ \&\ \beta _s=0.1) = 12.5$. From a different perspective, the inset in figure 4 shows how mesh adaptation helps us to achieve more accurate results.

$\bar {B}(\alpha _s=0.2\ \&\ \beta _s=0.1) = 12.5$. From a different perspective, the inset in figure 4 shows how mesh adaptation helps us to achieve more accurate results.

Figure 4. Features of the [R] problem for no-slip (in black) and sliding flow ![]() $\alpha _s=0.2\ \&\ \beta _s = 0.1$ (in red). Lines represent analytically calculated values (see appendix A.2): continuous lines,

$\alpha _s=0.2\ \&\ \beta _s = 0.1$ (in red). Lines represent analytically calculated values (see appendix A.2): continuous lines, ![]() $G^*$; dashed lines,

$G^*$; dashed lines, ![]() $j(\boldsymbol {u}^*)$; dashed-dotted line,

$j(\boldsymbol {u}^*)$; dashed-dotted line, ![]() $j_s (u_s)$. The black dotted line is the asymptotic scaling

$j_s (u_s)$. The black dotted line is the asymptotic scaling ![]() $2 B$ and red dotted line

$2 B$ and red dotted line ![]() $2 \alpha _s B = 0.4 B$. The asterisk symbols mark the computational data in the deforming regime and circle symbols in the fully sliding regime. Inset (

$2 \alpha _s B = 0.4 B$. The asterisk symbols mark the computational data in the deforming regime and circle symbols in the fully sliding regime. Inset (![]() $B=5, B_s = 1\ \&\ \beta _s =0.1$):

$B=5, B_s = 1\ \&\ \beta _s =0.1$): ![]() $j(\boldsymbol {u}^*)$ (cyan dashed line and asterisks) and

$j(\boldsymbol {u}^*)$ (cyan dashed line and asterisks) and ![]() $j_s (u_s)$ (cyan dashed-dotted line and asterisks) versus the cycles of mesh adaptation index with red lines showing the analytically calculated values in appendix A.2.

$j_s (u_s)$ (cyan dashed-dotted line and asterisks) versus the cycles of mesh adaptation index with red lines showing the analytically calculated values in appendix A.2.

4. Slippery particle motion

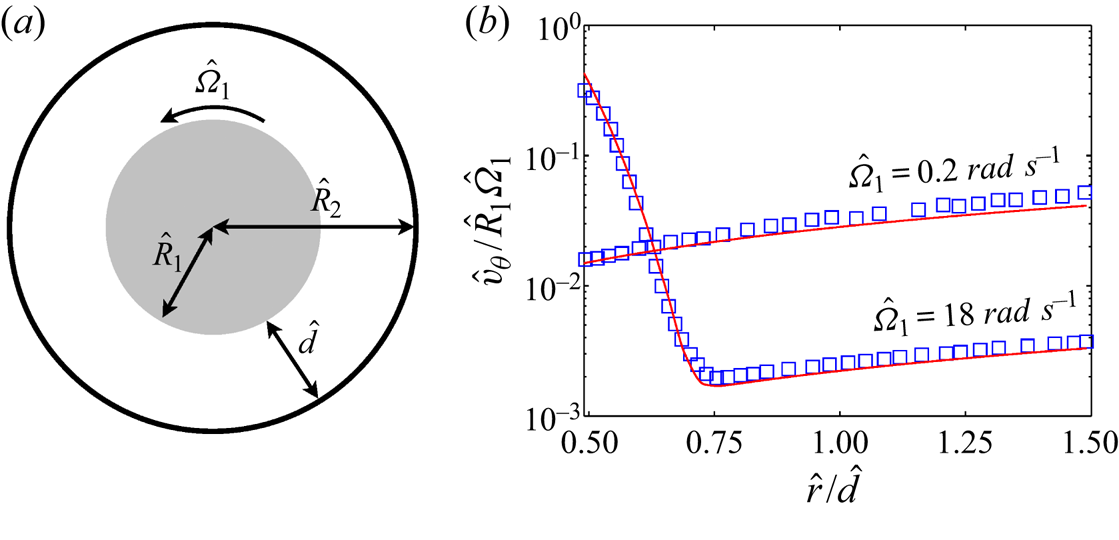

Particle motion in yield-stress fluids has been considered in numerous studies ranging from numerical simulations (Beris et al. Reference Beris, Tsamopoulos, Armstrong and Brown1985; Tokpavi, Magnin & Jay Reference Tokpavi, Magnin and Jay2008; Putz & Frigaard Reference Putz and Frigaard2010; Nirmalkar, Chhabra & Poole Reference Nirmalkar, Chhabra and Poole2012; Fraggedakis, Dimakopoulos & Tsamopoulos Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016; Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb; Izbassarov et al. Reference Izbassarov, Rosti, Ardekani, Sarabian, Hormozi, Brandt and Tammisola2018) to experimental validations/extensions (Jossic & Magnin Reference Jossic and Magnin2001; Putz et al. Reference Putz, Burghelea, Frigaard and Martinez2008; Tokpavi et al. Reference Tokpavi, Jay, Magnin and Jossic2009). Unfortunately, fewer studies are devoted to investigating the effect of slip on the flow field around the particle surface. Although Fraggedakis et al. (Reference Fraggedakis, Dimakopoulos and Tsamopoulos2016) used the Navier-slip law in their simulations, the emphasis of their study was on the effect of elasticity of the yield-stress fluid in the particle sedimentation problem. On the experimental side, Jossic & Magnin (Reference Jossic and Magnin2001) reported the drag coefficient of the particle moving in a Carbopol gel and showed that for particles with smooth surfaces, the drag coefficient is smaller compared with the rough particles that prevent slip which is intuitive. However, the mentioned authors did not quantify the slip velocity/law on the particle surface and rather qualitatively addressed the effect of slip. In this section, we will shed light on the effect of slippery motion of the yield-stress fluid about a circular two-dimensional (2-D) particle and in detail will address the yield limit under this condition.

Flow configuration: the horizontal symmetry axis of the particle is aligned with the ![]() $x$-axis (positive direction to the right) and the vertical one by

$x$-axis (positive direction to the right) and the vertical one by ![]() $y$-axis (positive direction upward) where the origin of the coordinate system is fixed at the particle centre. The fluid flow about the particle (

$y$-axis (positive direction upward) where the origin of the coordinate system is fixed at the particle centre. The fluid flow about the particle (![]() $X$) with its radius

$X$) with its radius ![]() $\hat {R}$ as the length scale can be described again by two formulations.

$\hat {R}$ as the length scale can be described again by two formulations.

(i) The [R] formulation, where the particle is dragged through the fluid with a prescribed velocity

$\hat {V}_p^*$ as the boundary condition. Hence, the drag force

$\hat {V}_p^*$ as the boundary condition. Hence, the drag force  $\hat {F}^*_D$ can be calculated. In this formulation,

$\hat {F}^*_D$ can be calculated. In this formulation,  $\hat {V}_p^*$ is used as the velocity scale and

$\hat {V}_p^*$ is used as the velocity scale and  $\hat {\mu } \hat {V}_p^* / \hat {R}$ as the characteristic viscous stress to scale the deviatoric stress tensor and the pressure, hence the governing equation is

(4.1)with (3.11) and (3.12) as the constitutive and the slip law, respectively, where

$\hat {\mu } \hat {V}_p^* / \hat {R}$ as the characteristic viscous stress to scale the deviatoric stress tensor and the pressure, hence the governing equation is

(4.1)with (3.11) and (3.12) as the constitutive and the slip law, respectively, where \begin{equation} {-}\boldsymbol{\nabla}p^* + \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{\tau}^*=0\quad \text{in}\ \varOmega \setminus \bar{X}\ \&\ \boldsymbol{u}_{ns}^*=-\boldsymbol{e}_y\quad \text{on}\ \partial X \end{equation}

\begin{equation} {-}\boldsymbol{\nabla}p^* + \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{\tau}^*=0\quad \text{in}\ \varOmega \setminus \bar{X}\ \&\ \boldsymbol{u}_{ns}^*=-\boldsymbol{e}_y\quad \text{on}\ \partial X \end{equation} $B=\hat {\tau }_y \hat {R}/ \hat {\mu } \hat {V}^*_p$. The drag force on the particle can be computed as a result from

(4.2)

$B=\hat {\tau }_y \hat {R}/ \hat {\mu } \hat {V}^*_p$. The drag force on the particle can be computed as a result from

(4.2) \begin{equation} a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + a_s (u^*_s,u^*_s) + B_s j_s (u^*_s) = \int_{\partial X} \left( \boldsymbol{\sigma}^* \boldsymbol{\cdot} \boldsymbol{n} \right) \boldsymbol{\cdot} \boldsymbol{e}_y \,\text{d}S = F^*_D. \end{equation}

\begin{equation} a(\boldsymbol{u}^*,\boldsymbol{u}^*) + B j(\boldsymbol{u}^*) + a_s (u^*_s,u^*_s) + B_s j_s (u^*_s) = \int_{\partial X} \left( \boldsymbol{\sigma}^* \boldsymbol{\cdot} \boldsymbol{n} \right) \boldsymbol{\cdot} \boldsymbol{e}_y \,\text{d}S = F^*_D. \end{equation}(ii) The [M] formulation, where the buoyancy of the particle is known and it falls freely under the action of the gravity

$-\hat {g} \boldsymbol {e}_y$. Hence, the settling velocity of the particle

$-\hat {g} \boldsymbol {e}_y$. Hence, the settling velocity of the particle  $\hat {V}_p$ can be calculated as a result. In this formulation, velocity is scaled with

$\hat {V}_p$ can be calculated as a result. In this formulation, velocity is scaled with  ${\rm \Delta} \hat {\rho } \hat {g} \hat {R}^2 / \hat {\mu }$: the velocity scale obtained via balancing the buoyancy stress with the characteristic viscous stress. Please note that here

${\rm \Delta} \hat {\rho } \hat {g} \hat {R}^2 / \hat {\mu }$: the velocity scale obtained via balancing the buoyancy stress with the characteristic viscous stress. Please note that here  $\hat {g}$ is the gravitational acceleration and

$\hat {g}$ is the gravitational acceleration and  ${\rm \Delta} \hat {\rho }$ is the density difference between the particle and the suspending fluid. Hence, the governing equation is

(4.3)where

${\rm \Delta} \hat {\rho }$ is the density difference between the particle and the suspending fluid. Hence, the governing equation is

(4.3)where \begin{equation} {-}\boldsymbol{\nabla}p + \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{\tau} - \frac{\rho}{1-\rho} \boldsymbol{e}_y =0\quad \text{in} \ \varOmega \setminus \bar{X}\ \text{and} \int_{\partial X} \left( \boldsymbol{\sigma} \boldsymbol{\cdot} \boldsymbol{n} \right) \boldsymbol{\cdot} \boldsymbol{e}_y \,\text{d}S=\frac{\rm \pi}{1-\rho} \end{equation}

\begin{equation} {-}\boldsymbol{\nabla}p + \boldsymbol{\nabla} \boldsymbol{\cdot} \boldsymbol{\tau} - \frac{\rho}{1-\rho} \boldsymbol{e}_y =0\quad \text{in} \ \varOmega \setminus \bar{X}\ \text{and} \int_{\partial X} \left( \boldsymbol{\sigma} \boldsymbol{\cdot} \boldsymbol{n} \right) \boldsymbol{\cdot} \boldsymbol{e}_y \,\text{d}S=\frac{\rm \pi}{1-\rho} \end{equation} $\rho$ is the ratio of the fluid density to the particle one (i.e.

$\rho$ is the ratio of the fluid density to the particle one (i.e.  $\hat {\rho }_f / \hat {\rho }_p$). The constitutive and slip laws are the same as (3.2) and (3.3), respectively, with a slight difference: the yield number

$\hat {\rho }_f / \hat {\rho }_p$). The constitutive and slip laws are the same as (3.2) and (3.3), respectively, with a slight difference: the yield number  $Y$ is substituted for the Oldroyd number in the particle sedimentation problem; indeed,

$Y$ is substituted for the Oldroyd number in the particle sedimentation problem; indeed,  $Y=\hat {\tau }_y / {\rm \Delta} \hat {\rho } \hat {g} \hat {R}$.

$Y=\hat {\tau }_y / {\rm \Delta} \hat {\rho } \hat {g} \hat {R}$.

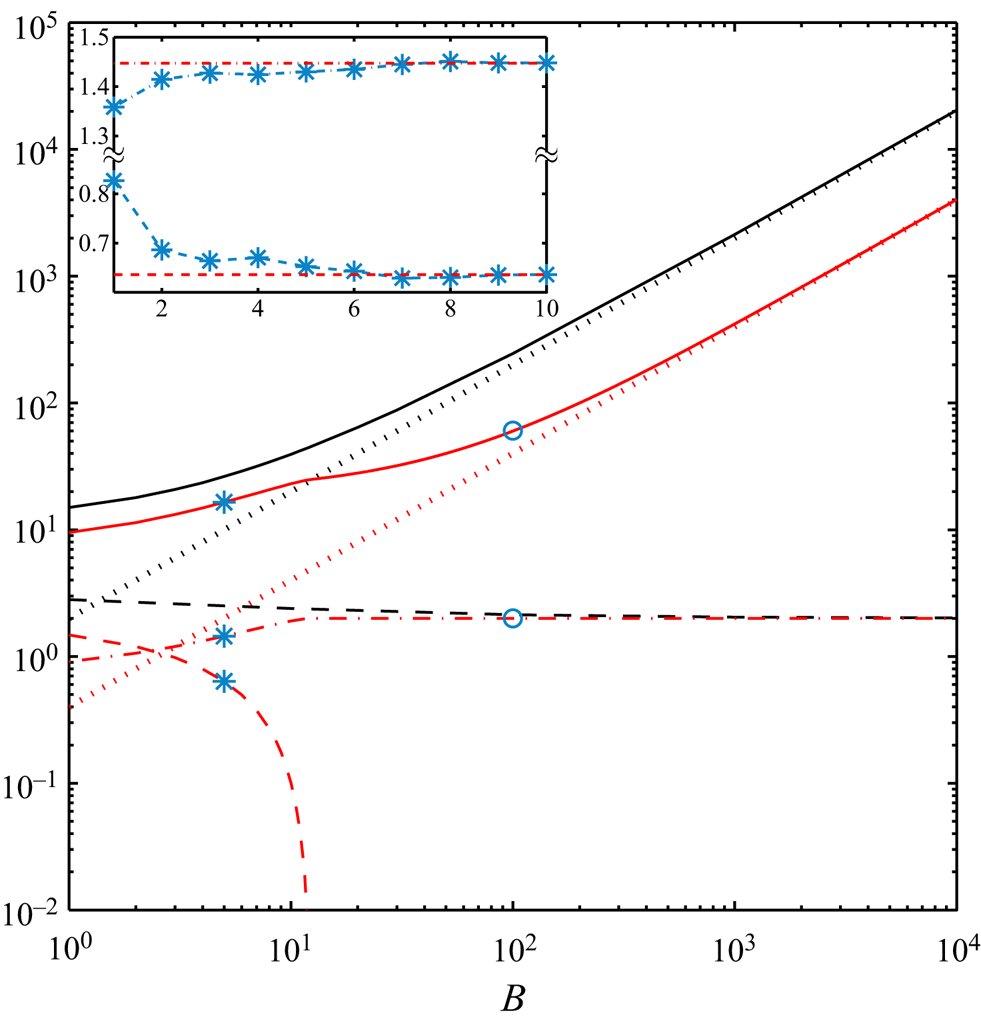

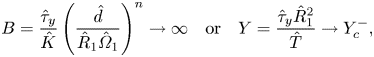

The yield limit can be well understood using either the [R] or [M] formulations knowing the mapping between these two formulations: ![]() $Y = {\rm \pi}B / F^*_D$ or

$Y = {\rm \pi}B / F^*_D$ or ![]() $B=Y/V_p$. In the [R] formulation, the particle never stops because the particle velocity is set as the boundary condition, yet, in the yield limit

$B=Y/V_p$. In the [R] formulation, the particle never stops because the particle velocity is set as the boundary condition, yet, in the yield limit ![]() $B \to \infty$, the drag force also goes to infinity. However, in the [M] problem, for a large enough yield number

$B \to \infty$, the drag force also goes to infinity. However, in the [M] problem, for a large enough yield number ![]() $(Y > Y_c)$, the yield stress can overcome the buoyancy of the particle and makes it stationary suspended. The connection between these two situations can be well discussed by the ‘plastic drag coefficient’,

$(Y > Y_c)$, the yield stress can overcome the buoyancy of the particle and makes it stationary suspended. The connection between these two situations can be well discussed by the ‘plastic drag coefficient’,

\begin{equation} C_D^p = \left\{ \begin{array}{@{}ll} \left[ \dfrac{\hat{F}^*_D}{\hat{\ell}_\bot \hat{\tau}_Y} \right]^{[\textrm{R}]} = \left[ \dfrac{F^*_D}{\ell_\bot B} \right]^{[\textrm{R}]} & \mbox{for problem [R]}, \\ \left[ \dfrac{ {\rm \Delta}\hat{\rho} \hat{g} \hat{A}_p}{\hat{\ell}_\bot \hat{\tau}_Y} \right]^{[\textrm{M}]} = \left[ \dfrac{\rm \pi}{\ell_\bot Y} \right]^{[\textrm{M}]} & \mbox{for problem [M]}, \end{array} \right. \end{equation}

\begin{equation} C_D^p = \left\{ \begin{array}{@{}ll} \left[ \dfrac{\hat{F}^*_D}{\hat{\ell}_\bot \hat{\tau}_Y} \right]^{[\textrm{R}]} = \left[ \dfrac{F^*_D}{\ell_\bot B} \right]^{[\textrm{R}]} & \mbox{for problem [R]}, \\ \left[ \dfrac{ {\rm \Delta}\hat{\rho} \hat{g} \hat{A}_p}{\hat{\ell}_\bot \hat{\tau}_Y} \right]^{[\textrm{M}]} = \left[ \dfrac{\rm \pi}{\ell_\bot Y} \right]^{[\textrm{M}]} & \mbox{for problem [M]}, \end{array} \right. \end{equation}

where ![]() $\ell _\bot$ is the width of the particle perpendicular to the flow direction (

$\ell _\bot$ is the width of the particle perpendicular to the flow direction (![]() $\ell _\bot =2$) and

$\ell _\bot =2$) and ![]() $\hat {A}_p$ is the area of the 2-D particle (i.e.

$\hat {A}_p$ is the area of the 2-D particle (i.e. ![]() ${\rm \pi} \hat {R}^2$ here). Then, the critical plastic drag coefficient (i.e. plastic drag coefficient at the yield limit) can be converted easily to the critical yield number,

${\rm \pi} \hat {R}^2$ here). Then, the critical plastic drag coefficient (i.e. plastic drag coefficient at the yield limit) can be converted easily to the critical yield number,

For more details please see Chaparian & Frigaard (Reference Chaparian and Frigaard2017b). For instance, for a 2-D circle, as has been extensively validated (Tokpavi et al. Reference Tokpavi, Magnin and Jay2008; Putz & Frigaard Reference Putz and Frigaard2010; Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb), the critical plastic drag coefficient under the no-slip condition is 11.94, which yields to ![]() $Y_c=0.1316$.

$Y_c=0.1316$.

Regarding the computational details, we conduct the same strategy as in our previous studies (Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb; Iglesias et al. Reference Iglesias, Mercier, Chaparian and Frigaard2020). The computational box (![]() $\varOmega$) is chosen large enough to ensure independency from far-field conditions (Chaparian, Wachs & Frigaard Reference Chaparian, Wachs and Frigaard2018). The boundary condition

$\varOmega$) is chosen large enough to ensure independency from far-field conditions (Chaparian, Wachs & Frigaard Reference Chaparian, Wachs and Frigaard2018). The boundary condition ![]() $\boldsymbol {u}^*=0$ is enforced on

$\boldsymbol {u}^*=0$ is enforced on ![]() $\partial \varOmega$.

$\partial \varOmega$.

The yield limit of particle motion in a quiescent yield-stress fluid is directly relevant to the lateral resistance of an object (e.g. a pile) in a perfectly plastic medium (e.g. soil) which can be investigated by method of characteristics (i.e. slipline solution) due to the hyperbolic nature of the equations. We briefly revisit this problem in the next subsection.

4.1. Revisiting the slipline solution and lower- and upper-bound calculations

In a deformed perfectly plastic medium, the second invariant of the stress is equal to ![]() $B$ everywhere. The equilibrium equations for the unrestricted 2-D plastic flow then form a closed set of hyperbolic equations for which there are two families of orthogonal characteristic lines: the

$B$ everywhere. The equilibrium equations for the unrestricted 2-D plastic flow then form a closed set of hyperbolic equations for which there are two families of orthogonal characteristic lines: the ![]() $\alpha$- and

$\alpha$- and ![]() $\beta$-families (Hill Reference Hill1950; Chakrabarty Reference Chakrabarty2012). Physically, these lines (termed as sliplines) show the direction of the maximum shear stress which is equal to

$\beta$-families (Hill Reference Hill1950; Chakrabarty Reference Chakrabarty2012). Physically, these lines (termed as sliplines) show the direction of the maximum shear stress which is equal to ![]() $B$. Properties of these lines facilitate studying the ‘yield limit’ in various viscoplastic problems (Dubash et al. Reference Dubash, Balmforth, Slim and Cochard2009; Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb; Chaparian & Nasouri Reference Chaparian and Nasouri2018; Hewitt & Balmforth Reference Hewitt and Balmforth2018). However, finding the sliplines itself is not trivial in some complex problems. Indeed, the sliplines assist us in postulating admissible stress and velocity fields which yield to finding the lower and upper bounds, respectively, of the load limit.

$B$. Properties of these lines facilitate studying the ‘yield limit’ in various viscoplastic problems (Dubash et al. Reference Dubash, Balmforth, Slim and Cochard2009; Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb; Chaparian & Nasouri Reference Chaparian and Nasouri2018; Hewitt & Balmforth Reference Hewitt and Balmforth2018). However, finding the sliplines itself is not trivial in some complex problems. Indeed, the sliplines assist us in postulating admissible stress and velocity fields which yield to finding the lower and upper bounds, respectively, of the load limit.

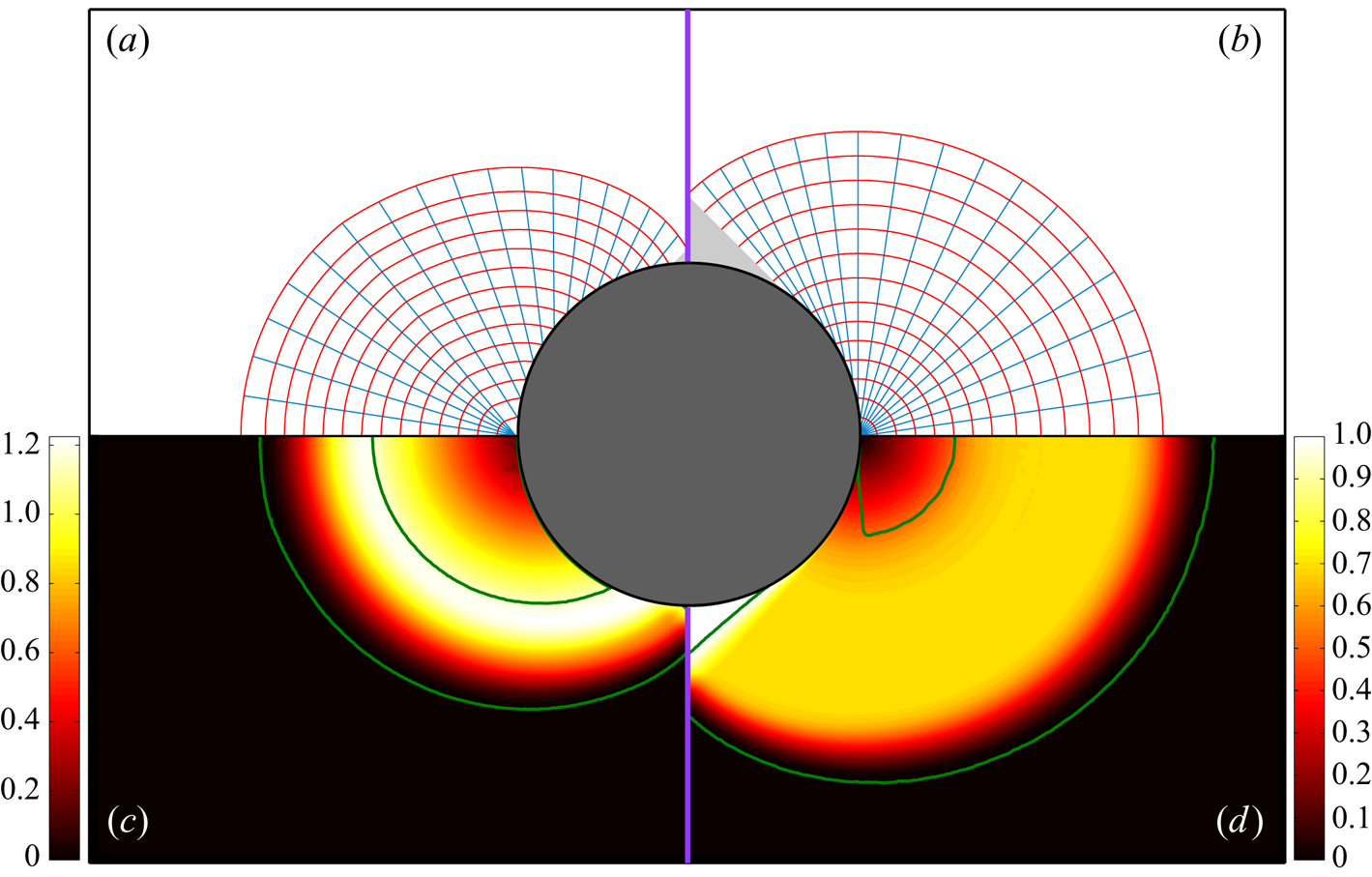

Initially investigated by Randolph & Houlsby (Reference Randolph and Houlsby1984), a slipline solution was devised for calculating the lateral resistance of a circular pile in soil (considered as a perfectly plastic material), taking into account the effect of soil adhesion at the pile–soil interface, ![]() $\widetilde {\alpha _s}$. In other words, the tangential shear stress at the pile-soil interface is assumed to be equal to

$\widetilde {\alpha _s}$. In other words, the tangential shear stress at the pile-soil interface is assumed to be equal to ![]() $\tilde {\alpha }_s B$. Although widely believed that the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution is exact (lower and upper bounds of the load/drag are the same for the whole range of

$\tilde {\alpha }_s B$. Although widely believed that the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution is exact (lower and upper bounds of the load/drag are the same for the whole range of ![]() $\tilde {\alpha }_s$), an issue was firstly detected by Murff, Wagner & Randolph (Reference Murff, Wagner and Randolph1989): for

$\tilde {\alpha }_s$), an issue was firstly detected by Murff, Wagner & Randolph (Reference Murff, Wagner and Randolph1989): for ![]() $\tilde {\alpha }_s < 1$, there is a region in the vicinity of the pile surfaces in which the rate of strain is negative and its absolute value should be taken into account in calculating the upper bound to avoid negative plastic dissipation. If one does so, then there is a discrepancy between the lower and upper bounds. Later, Martin & Randolph (Reference Martin and Randolph2006) proposed two new postulated velocity fields which improved the upper-bound predictions to some extent; one for small (

$\tilde {\alpha }_s < 1$, there is a region in the vicinity of the pile surfaces in which the rate of strain is negative and its absolute value should be taken into account in calculating the upper bound to avoid negative plastic dissipation. If one does so, then there is a discrepancy between the lower and upper bounds. Later, Martin & Randolph (Reference Martin and Randolph2006) proposed two new postulated velocity fields which improved the upper-bound predictions to some extent; one for small (![]() $\tilde {\alpha }_s \to 0$) and the other one for large (

$\tilde {\alpha }_s \to 0$) and the other one for large (![]() $\tilde {\alpha }_s \to 1$) soil adhesion factors. By combining these two mechanisms, Martin & Randolph (Reference Martin and Randolph2006) proposed an alternative mechanism which markedly shrinks the uncertainty between the lower and upper bounds predictions for the entire range of

$\tilde {\alpha }_s \to 1$) soil adhesion factors. By combining these two mechanisms, Martin & Randolph (Reference Martin and Randolph2006) proposed an alternative mechanism which markedly shrinks the uncertainty between the lower and upper bounds predictions for the entire range of ![]() $\tilde {\alpha }_s$. We will quickly review the lower- (Randolph & Houlsby Reference Randolph and Houlsby1984) and upper-bound (Martin & Randolph Reference Martin and Randolph2006) solutions here; however, for more details, readers are referred to the original references.

$\tilde {\alpha }_s$. We will quickly review the lower- (Randolph & Houlsby Reference Randolph and Houlsby1984) and upper-bound (Martin & Randolph Reference Martin and Randolph2006) solutions here; however, for more details, readers are referred to the original references.

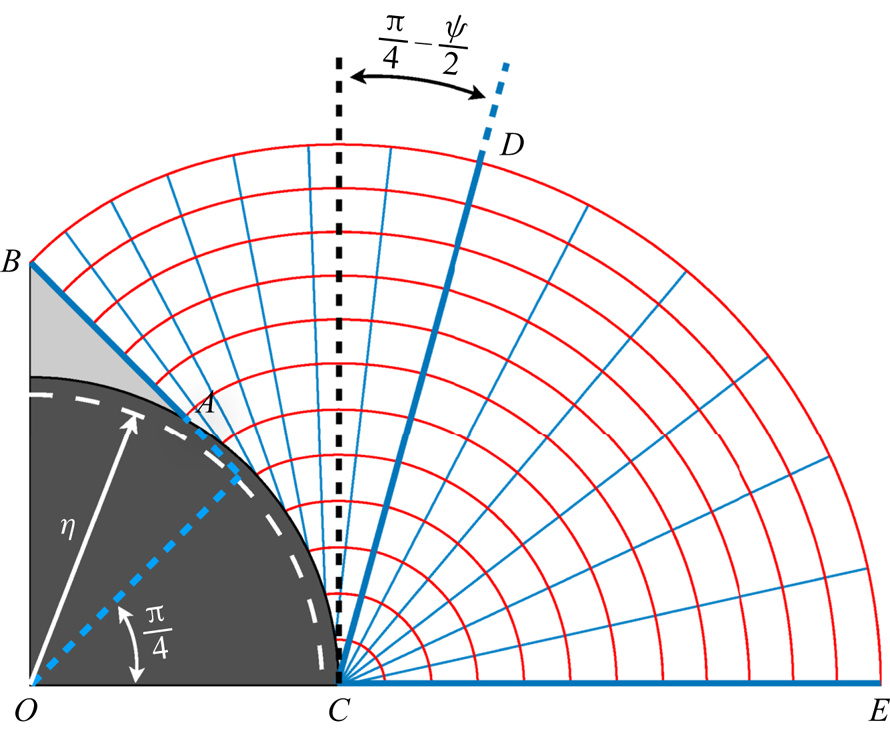

The first family of sliplines in this problem are straight lines that make a ![]() ${{\rm \pi} }/{4}-{\psi }/{2}$ angle with the pile surface (say

${{\rm \pi} }/{4}-{\psi }/{2}$ angle with the pile surface (say ![]() $\alpha$-lines) where

$\alpha$-lines) where ![]() $\psi =\sin ^{-1} \tilde {\alpha }_s$. Figure 5 represents these lines in cyan colour. The initial

$\psi =\sin ^{-1} \tilde {\alpha }_s$. Figure 5 represents these lines in cyan colour. The initial ![]() $\alpha$-line is

$\alpha$-line is ![]() $AB$ which makes a

$AB$ which makes a ![]() ${\rm \pi} /4$ angle with the vertical symmetry line since

${\rm \pi} /4$ angle with the vertical symmetry line since ![]() $\tilde {\tau }_{xy}$ is zero on

$\tilde {\tau }_{xy}$ is zero on ![]() $OB$. Hence, the region enclosed between

$OB$. Hence, the region enclosed between ![]() $AB$ and the pile surface is the plug region shown in light grey. The

$AB$ and the pile surface is the plug region shown in light grey. The ![]() $\alpha$-lines from

$\alpha$-lines from ![]() $AB$ to

$AB$ to ![]() $CD$ can be found easily as discussed above; the corresponding

$CD$ can be found easily as discussed above; the corresponding ![]() $\beta$-lines are curved lines which are the involutes unwrapped from an imaginary concentric circle – the evolute – with radius

$\beta$-lines are curved lines which are the involutes unwrapped from an imaginary concentric circle – the evolute – with radius ![]() $\eta =\cos (\frac {1}{2} \cos ^{-1} \tilde {\alpha }_s )$ shown with a dashed white line. Please note that indeed

$\eta =\cos (\frac {1}{2} \cos ^{-1} \tilde {\alpha }_s )$ shown with a dashed white line. Please note that indeed ![]() $\alpha$-lines can be introduced as tangents of this imaginary circle as well. From

$\alpha$-lines can be introduced as tangents of this imaginary circle as well. From ![]() $CD$ to

$CD$ to ![]() $CE$,

$CE$, ![]() $\alpha$-lines are spokes of a fan centred at

$\alpha$-lines are spokes of a fan centred at ![]() $C$; hence, the

$C$; hence, the ![]() $\beta$-lines in this part are arcs of concentric circles at point

$\beta$-lines in this part are arcs of concentric circles at point ![]() $C$.

$C$.

Figure 5. Schematic of the sliplines about a 2-D circle. The ![]() $\alpha$-lines are in cyan colour and

$\alpha$-lines are in cyan colour and ![]() $\beta$-lines in red. Only a quarter of the whole domain is shown due to symmetry.

$\beta$-lines in red. Only a quarter of the whole domain is shown due to symmetry.