1. Introduction

Atomization of planar liquid sheets in a gas medium is the most fundamental process of many liquid atomization techniques. Destabilization of the surface wave is the initial stage of the atomization of liquid sheets, significantly affecting atomization quality, so sound knowledge of the instability of planar liquid sheets is not only scientifically valuable but also necessary for the design and application of practical systems.

Kelvin–Helmholtz (K–H) instability is induced by the difference in velocity between two fluid layers (Kelvin Reference Kelvin1871). This difference can amplify the pressure difference between a wave crest and a trough, which also plays a dominant role in the atomization of liquid sheets (Lin Reference Lin2003). For this reason, researchers have investigated the mechanism of the instability of liquid sheets in a steady gas medium both theoretically and experimentally. Using a linear method, Squire (Reference Squire1953) analysed the K–H instability of a planar inviscid liquid sheet in an inviscid gas medium. The most unstable wavelength and growth rates were obtained, and his theoretical results qualitatively agreed with experimental results obtained from a swirling liquid sheet, indicating that the K–H instability was the dominant mechanism of the destabilization of the liquid sheet. Dombrowski & Johns (Reference Dombrowski and Johns1963) considered viscosity and thinning of a liquid sheet, obtaining a drop-size relationship that compared favourably with their experimental data. Crapper, Dombrowski & Pyott (Reference Crapper, Dombrowski and Pyott1975) conducted an experimental study on large-amplitude waves; however, the linear theory could not predict the growth rate well. Li & Tankin (Reference Li and Tankin1991) studied the temporal instability of a viscous liquid sheet in the presence of an inviscid gas medium using linear theory. In addition to aerodynamic instability, they found that the viscosity enhanced the instability region, influenced by variation in the liquid viscosity. More recently, Ye, Yang & Fu (Reference Ye, Yang and Fu2016) investigated the spatial instability of a double-layer viscous liquid sheet moving in a stationary viscous gas medium. The gas velocity profile was non-uniform, and the stability problem was solved by a spectral collocation method. The accuracy of this method was verified to some extent by Dighe & Gadgil (Reference Dighe and Gadgil2021). Moreover, Qin, Yi & Yang (Reference Qin, Yi and Yang2018) established a theoretical breakup model of an air-assisted planar liquid sheet based on linear stability analysis and the full-wave integral. They divided the unstable stages into K–H and Rayleigh–Taylor stages. Using this theory, the Sauter mean diameter (SMD) was successfully predicted, indicating the effectiveness of the linear stability theory in estimating atomization.

All of the research mentioned above focused on the condition of a liquid sheet breakup without outer excitations, but combustion instability may lead to acoustic oscillations in rocket engines and aircraft engines that affect the instability of liquid sheets (Christou, Stelzner & Zarzalis Reference Christou, Stelzner and Zarzalis2021). For this reason, it is necessary to consider outer excitations. Using liquid propellant rocket engines as an example, axial, radial and tangential unstable modes may exist (Yang & Anderson Reference Yang and Anderson1995). In these engines, the acoustic dimension of the acoustic wave is much larger than that of the liquid jet, so the radial and tangential acoustic modes can both be regarded as acoustic waves that are perpendicular to the liquid stream. Miesse (Reference Miesse1955) conducted an experimental study on the instability of a liquid jet in an acoustic field; his results showed that the perpendicular acoustic field dispersed the droplets in a diverging sinusoidal configuration, while the parallel acoustic field coalesced the droplets as a result of the velocity variation of successive fluid particles. From this work, many researchers have focused on the effect of different acoustic modes.

For the acoustic field perpendicular to the jet stream, Baillot et al. (Reference Baillot, Blaisot, Boisdron and Dumouchel2009) investigated the behaviour of an air-assisted jet submitted to a transverse high-frequency acoustic field in a standing wave; acoustic levels were produced up to 165 dB. When the liquid jet was placed at the pressure antinode, its breakup was only affected by acoustics if it was assisted by the coaxial gas flow. Nevertheless, when the liquid jet was placed at the pressure node, it was flattened by the acoustic radiation pressure, and the acoustic oscillation caused Faraday waves to rise. Similar results were reported by Carpentier et al. (Reference Carpentier, Baillot, Blaisot and Dumouchel2009) and Ficuciello et al. (Reference Ficuciello, Baillot, Blaisot, Richard and Theron2016). Ficuciello et al. (Reference Ficuciello, Blaisot, Richard and Baillot2017) investigated droplet clustering in this atomizing condition. Mulmule, Tirumkudulu & Ramamurthi (Reference Mulmule, Tirumkudulu and Ramamurthi2010) studied the instability of a moving liquid sheet in the presence of acoustic forcing both experimentally and theoretically. They analysed the surface instability using Floquet theory and found that the instability was due to the coupling effect of K–H and parametric instabilities, which agreed with the most unstable wavelength obtained in the experiment. However, the model was not able to predict the observed variation in sound pressure level with forcing frequency or reproduce the pronounced response at discrete frequencies. More recently, Dighe & Gadgil (Reference Dighe and Gadgil2018, Reference Dighe and Gadgil2019a,Reference Dighe and Gadgilb, Reference Dighe and Gadgil2021) conducted systematic experimental studies on the instability of a liquid sheet formed by the oblique impingement of two liquid jets. The sound pressure levels were set below 120 dB, much lower than those set by Baillot et al. (Reference Baillot, Blaisot, Boisdron and Dumouchel2009); thus, the acoustic field did not excite the parametric instability of the surface wave, and the acoustic excitations could be regarded as a small disturbance while the basic flows of the liquid and gas phases were still steady. They found that the regions were dominated by the aerodynamic forces and the thinning effect of the liquid sheet. The two different unstable modes were divided theoretically according to the theories of Squire (Reference Squire1953), Ye et al. (Reference Ye, Yang and Fu2016), Tirumkudulu & Paramati (Reference Tirumkudulu and Paramati2013) and Paramati, Tirumkudulu & Schmid (Reference Paramati, Tirumkudulu and Schmid2015). Dighe & Gadgil (Reference Dighe and Gadgil2021) clearly explained the different mechanisms of instability in their research when the liquid sheet was in the presence of a weak acoustic field. However, when the acoustic field was much stronger, the basic flow was unsteady. More study may be required to solve this problem.

In the acoustic field parallel to the jet stream, Sivadas, Fernandes & Heitor (Reference Sivadas, Fernandes and Heitor2003) and Sivadas et al. (Reference Sivadas, Balaji, Sampathkumar, Hassan, Karthik and Saidileep2016) experimentally investigated the breakup length of the liquid jet and the sheet corresponding to the sound intensity; they established empirical formulas between the breakup length and the acoustic number. More recently, Chaussonnet et al. (Reference Chaussonnet, Muller, Holz, Koch and Bauer2017) conducted an experimental study on prefilming airblast atomization in an oscillating air flow field and obtained a SMD prediction model based on linear stability theory in a steady basic flow. A quasi-steady theory was adopted to simulate the gas velocity oscillations. The theoretical model predicted the periodic variation of the SMD well, and the results showed that the time variation of the SMD was accompanied by a low-pass behaviour. The SMD exhibited almost no fluctuations at high frequencies. Using a similar experimental system, Christou et al. (Reference Christou, Stelzner and Zarzalis2021) investigated frequency and phase differences between gas velocity and the SMD; they also analysed the temporal instability of viscous and non-Newtonian planar liquid sheets in the presence of gas velocity oscillations based on the Floquet theory (Yang et al. Reference Yang, Jia, Fu and Yang2018; Jia et al. Reference Jia, Xie, Yang, Fu and Cui2019) and revealed the mechanism of the K–H and parametric unstable modes using an energy budget theory. Experimental studies are required to verify their theoretical results.

It can be concluded from previous studies that in air-assisted atomization, acoustic oscillations can give rise to gas velocity oscillations, modulating the instability of the surface wave. This modulating effect may trigger unstable combustion. Nevertheless, few experimental studies have investigated the detailed evolution of the surface wave of a planar liquid sheet in the presence of axial gas velocity oscillations. Therefore, an experimental study was conducted on the oscillatory K–H instability of a planar liquid sheet in the presence of oscillating axial gas flow. In § 2, the experimental system is introduced, including the system set-up, the linear stability analysis of the spatial instability of the liquid sheet and the measurement methods. In § 3, the experimentally obtained growth rates are discussed and compared with the theoretical results. Moreover, different unstable modes are discovered, and linear stability theory is used to divide the regimes of these modes. Finally, in § 4, conclusions are presented.

2. Experimental system set-up

2.1. Experimental system and equipment

A systematic experimental study was conducted in this work to investigate the characteristics of the surface wave. The experimental system is shown in figure 1, which displays the spray system and the measuring system. A sinusoidal signal was generated by a function signal generator (UTG2062A, 60 MHz sine wave output, and resolution of 1 μHz and 14 bit) and amplified by a power amplifier (BNB A-1800, frequency range 20 Hz–20 kHz and power 1800 W), driving a loudspeaker (MB15, size 15 inches, frequency range 35–2500 Hz, power 1000 W, sensitivity 97 dB and resistance 8 ![]() $\varOmega$) to produce an intense acoustic oscillation. This acoustic oscillation generated an oscillating gas flow at the exit of the nozzle. The liquid was supplied by a booster pump (maximum flow rate 18 L min−1 and maximum head of delivery 20 m). Gas velocity was measured by a microphone (BSWA TECH MA401 and MPA421) after standardization by a hot wire (Dantec Dynamics Mini CTA 54T42). The liquid flow rate was measured by a turbine flowmeter (LWGB-4ZX, measuring range 0–0.25 m3 h−1 and precision ±5 %). HIVISION Cube 7 (minimum exposure time 2 μs, maximum fps 28 500 and maximum resolution 1696 × 1710 pixels) and Photron SA-Z (minimum exposure time 159 ns, maximum fps 21 000 and maximum resolution 1024 × 1024 pixels) high-speed cameras were used to determine the morphology of the surface wave on the side and front views, respectively.

$\varOmega$) to produce an intense acoustic oscillation. This acoustic oscillation generated an oscillating gas flow at the exit of the nozzle. The liquid was supplied by a booster pump (maximum flow rate 18 L min−1 and maximum head of delivery 20 m). Gas velocity was measured by a microphone (BSWA TECH MA401 and MPA421) after standardization by a hot wire (Dantec Dynamics Mini CTA 54T42). The liquid flow rate was measured by a turbine flowmeter (LWGB-4ZX, measuring range 0–0.25 m3 h−1 and precision ±5 %). HIVISION Cube 7 (minimum exposure time 2 μs, maximum fps 28 500 and maximum resolution 1696 × 1710 pixels) and Photron SA-Z (minimum exposure time 159 ns, maximum fps 21 000 and maximum resolution 1024 × 1024 pixels) high-speed cameras were used to determine the morphology of the surface wave on the side and front views, respectively.

Figure 1. Experimental system. 1, Data acquisition system; 2, HSVISION Cube 7 high-speed camera; 3, Photron SA-Z high-speed camera; 4, gas‒liquid coaxial atomizer; 5, loudspeaker; 6, microphones; 7, turbine flowmeter; 8, booster pump; 9, power amplifier; 10, function signal generator.

Because of the effect of surface tension, the edges of the liquid sheet contracted (as shown in figure 2a); for this reason, two cotton threads were used to direct the liquid sheet, as shown in figure 2(b).

Figure 2. Directing effect of cotton threads. (a) Without directing. (b) With directing.

The gas and liquid phases were ejected from the slits, as shown in figure 3. The sizes of the liquid and gas nozzles were ![]() $40\ \textrm{mm} \times 0.4\ \textrm{mm}$ and

$40\ \textrm{mm} \times 0.4\ \textrm{mm}$ and ![]() $40\ \textrm{mm} \times 2\ \textrm{mm}$, respectively. Liquid viscosity was measured by a rheometer (Anton Paar MCR92). Surface tension was measured using a surface tension meter (JYW-200C, measuring range 0–200 mN m−1, resolution 0.01 mN m−1, error range ±5 %). The liquid density was measured with a densimeter (Qingxian Yanhe Instrument Co. Ltd, resolution 1 kg m−3).

$40\ \textrm{mm} \times 2\ \textrm{mm}$, respectively. Liquid viscosity was measured by a rheometer (Anton Paar MCR92). Surface tension was measured using a surface tension meter (JYW-200C, measuring range 0–200 mN m−1, resolution 0.01 mN m−1, error range ±5 %). The liquid density was measured with a densimeter (Qingxian Yanhe Instrument Co. Ltd, resolution 1 kg m−3).

Figure 3. Gas‒liquid coaxial atomizer.

According to Tammisola et al. (Reference Tammisola, Sasaki, Lundell, Matsubara and Söderberg2011) and Asare, Takahashi & Hoffman (Reference Asare, Takahashi and Hoffman1981), the thickness of the liquid sheet is close to the thickness of the nozzle, so the thickness of the liquid sheet in the present study is regarded as the thickness of the nozzle. To prevent the wetting effect, a hydrophobic coating was applied at the nozzle exit to guarantee the liquid sheet thickness and a relatively uniform liquid velocity profile.

2.2. Stability analysis

To explain the growth rates and the waveforms of the surface wave, a stability analysis should be conducted. A two-dimensional viscous liquid sheet moving through an oscillating inviscid gas medium was considered in this work. As shown in figure 4, the x and y axes were parallel and perpendicular to the liquid stream, respectively. The disturbance oscillated temporally and grew spatially. For the basic flow, the liquid velocity was ![]() ${U_l}$, and the gas velocity

${U_l}$, and the gas velocity ![]() ${U_g}$ oscillated in the following form:

${U_g}$ oscillated in the following form:

where ![]() ${U_{g,\textrm{0}}}$ is the mean gas velocity,

${U_{g,\textrm{0}}}$ is the mean gas velocity, ![]() $\mathrm{\Delta }U$ is the gas velocity oscillation amplitude,

$\mathrm{\Delta }U$ is the gas velocity oscillation amplitude, ![]() ${\omega _s}$ is the oscillation frequency and t is time.

${\omega _s}$ is the oscillation frequency and t is time.

Figure 4. Spatial instability of planar liquid sheet in (a) sinuous and (b) varicose modes.

The linear instability of a viscoelastic planar liquid sheet in the presence of gas velocity oscillations was investigated in previous studies by the authors (Jia et al. Reference Jia, Xie, Yang, Fu and Cui2019). Therefore, in the present study, the dispersion relation was obtained from these results instead of being derived from the governing equations again. Appendix A shows the detailed process of obtaining the dispersion relationship of the temporal stability of viscous planar liquid sheets in the presence of gas oscillations.

However, the present study focused on the spatial instability of a surface wave, and the reference system influenced the spatial growth rate. Hence, the basic flow of the liquid sheet could not be regarded as static but rather as moving with an axial velocity ![]() ${U_l}$ (parallel to the x axis). In Appendix A, the coordinate system moved with the liquid sheet, but the spatial disturbance occurred near the nozzle exit. An alteration of the reference system was conducted. According to (A29), the phase velocity of the surface is

${U_l}$ (parallel to the x axis). In Appendix A, the coordinate system moved with the liquid sheet, but the spatial disturbance occurred near the nozzle exit. An alteration of the reference system was conducted. According to (A29), the phase velocity of the surface is

where ![]() $\beta $ is the characteristic exponent of the Floquet solution, n is the order number of the Fourier series and

$\beta $ is the characteristic exponent of the Floquet solution, n is the order number of the Fourier series and ![]() ${k_r} = 2{\rm \pi}/\lambda $ is the real part of the wavenumber, where

${k_r} = 2{\rm \pi}/\lambda $ is the real part of the wavenumber, where ![]() $\lambda $ is the wavelength of the surface wave. This phase velocity

$\lambda $ is the wavelength of the surface wave. This phase velocity ![]() ${u_{pn}}$ was relative to the basic flow of the liquid sheet. Relative to the nozzle exit, the phase velocity should be

${u_{pn}}$ was relative to the basic flow of the liquid sheet. Relative to the nozzle exit, the phase velocity should be

According to the phase velocity, after altering the reference system, the frequency of the surface wave was

Meanwhile, in the spatially unstable mode, the real part of ![]() $\beta $ was zero (without temporal growth), and the imaginary part of wavenumber

$\beta $ was zero (without temporal growth), and the imaginary part of wavenumber ![]() ${k_i}$ represented the opposite number of the spatial growth rate. As a result, (2.4) can be expressed as

${k_i}$ represented the opposite number of the spatial growth rate. As a result, (2.4) can be expressed as

According to the above transformation, the dispersion relation of the spatial instability can also be expressed in the form of (A30)–(A33), with the expression of ![]() ${\omega _{en}}$:

${\omega _{en}}$:

and the expression of ![]() ${U_\textrm{0}}$ is

${U_\textrm{0}}$ is

Moreover, the dispersion relation can also be expressed in non-dimensional form:

\begin{gather}

\boldsymbol{\bar{\boldsymbol{\mathsf{A}}}\bar{\eta

}} = \left( {\begin{array}{@{}ccccccc@{}} \ddots & \vdots &

\vdots & \vdots & \vdots & \vdots &

{\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} \\

\cdots &{\overline {{{\mathsf{D}}_{ - 2}}} }&{\overline {{{\mathsf{G}}_{ - 1}}}

}&{\overline {{\mathsf{F}}} } & 0 & 0 & \cdots \\

\cdots &{\overline {{{\mathsf{E}}_{-2}}} }&{\overline {{{\mathsf{D}}_{ - 1}}} }&{\overline {{{\mathsf{G}}_0}}

}&{\overline{{\mathsf{F}}}} & 0 & \cdots \\

\cdots &{\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_{ - 1}}} }&{\overline {{{\mathsf{D}}_0}} }&{\overline{{{\mathsf{G}}_1}} }

&{\overline{{\mathsf{F}}}}& \cdots \\

\cdots & 0 & {\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_0}} }&{\overline {{{\mathsf{D}}_1}} }

&{\overline{{{\mathsf{G}}_2}} }& \cdots \\

\cdots & 0 & 0 &{\overline{{\mathsf{F}}}}&{\overline{{{\mathsf{E}}_1}} }&{\overline {{{\mathsf{D}}_2}} }& \cdots \\

{\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} &

\vdots & \vdots & \vdots & \vdots & \vdots & \ddots

\end{array}} \right)\left({\begin{array}{@{}c@{}} \vdots

\\ {\overline {{\eta_{_{-2}}}} }\\ {\overline {{\eta_{_{-1}}}} }\\

{\overline {{\eta_{_0}}} }\\ {\overline {{\eta_{_1}}}

}\\ {\overline {{\eta_{_2}}} }\\ \vdots \end{array}} \right) =

\boldsymbol{0},\end{gather}

\begin{gather}

\boldsymbol{\bar{\boldsymbol{\mathsf{A}}}\bar{\eta

}} = \left( {\begin{array}{@{}ccccccc@{}} \ddots & \vdots &

\vdots & \vdots & \vdots & \vdots &

{\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} \\

\cdots &{\overline {{{\mathsf{D}}_{ - 2}}} }&{\overline {{{\mathsf{G}}_{ - 1}}}

}&{\overline {{\mathsf{F}}} } & 0 & 0 & \cdots \\

\cdots &{\overline {{{\mathsf{E}}_{-2}}} }&{\overline {{{\mathsf{D}}_{ - 1}}} }&{\overline {{{\mathsf{G}}_0}}

}&{\overline{{\mathsf{F}}}} & 0 & \cdots \\

\cdots &{\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_{ - 1}}} }&{\overline {{{\mathsf{D}}_0}} }&{\overline{{{\mathsf{G}}_1}} }

&{\overline{{\mathsf{F}}}}& \cdots \\

\cdots & 0 & {\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_0}} }&{\overline {{{\mathsf{D}}_1}} }

&{\overline{{{\mathsf{G}}_2}} }& \cdots \\

\cdots & 0 & 0 &{\overline{{\mathsf{F}}}}&{\overline{{{\mathsf{E}}_1}} }&{\overline {{{\mathsf{D}}_2}} }& \cdots \\

{\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} &

\vdots & \vdots & \vdots & \vdots & \vdots & \ddots

\end{array}} \right)\left({\begin{array}{@{}c@{}} \vdots

\\ {\overline {{\eta_{_{-2}}}} }\\ {\overline {{\eta_{_{-1}}}} }\\

{\overline {{\eta_{_0}}} }\\ {\overline {{\eta_{_1}}}

}\\ {\overline {{\eta_{_2}}} }\\ \vdots \end{array}} \right) =

\boldsymbol{0},\end{gather}

\begin{gather}

\left. {\begin{array}{c@{}} \begin{array}{c@{}} \overline{{{\mathsf{D}}_n}} = Oh({K^2} + L_n^2)({\varOmega_{en}} +

2Oh{K^\textrm{2}})\tanh (K) - 4O{h^2}{K^3}{L_n}\tanh

({L_n}) + {K^3}\\ + \rho \varOmega_{en}^2 +

2\textrm{i}\rho K{\varOmega_{en}}\sqrt {We} - \rho {K^2}We -

\dfrac{{\rho {K^2}{\varepsilon^2}We}}{2}, \end{array}\\

{\overline {{{\mathsf{E}}_n}} = \textrm{i}\rho

K{\varOmega_{en}}\varepsilon \sqrt {We} - \rho

{K^2}\varepsilon We - \frac{{\rho K{\varOmega_s}\varepsilon

\sqrt {We} }}{2},}\\ {\overline {{{\mathsf{G}}_n}} = \textrm{i}\rho

K{\varOmega_{en}}\varepsilon \sqrt {We} - \rho

{K^2}\varepsilon We + \frac{{\rho K{\varOmega_s}\varepsilon

\sqrt {We} }}{2},}\\ {\bar{{\mathsf{F}}} = \frac{{ - \rho

{K^2}{\varepsilon^2}We}}{4},}\\ {{\varOmega_{en}} = {{\rm

B}_2} + \textrm{i}K\sqrt {W{e_\textrm{l}}} +

\textrm{i}n{\varOmega_s}} \end{array}}\right\},\end{gather}

\begin{gather}

\left. {\begin{array}{c@{}} \begin{array}{c@{}} \overline{{{\mathsf{D}}_n}} = Oh({K^2} + L_n^2)({\varOmega_{en}} +

2Oh{K^\textrm{2}})\tanh (K) - 4O{h^2}{K^3}{L_n}\tanh

({L_n}) + {K^3}\\ + \rho \varOmega_{en}^2 +

2\textrm{i}\rho K{\varOmega_{en}}\sqrt {We} - \rho {K^2}We -

\dfrac{{\rho {K^2}{\varepsilon^2}We}}{2}, \end{array}\\

{\overline {{{\mathsf{E}}_n}} = \textrm{i}\rho

K{\varOmega_{en}}\varepsilon \sqrt {We} - \rho

{K^2}\varepsilon We - \frac{{\rho K{\varOmega_s}\varepsilon

\sqrt {We} }}{2},}\\ {\overline {{{\mathsf{G}}_n}} = \textrm{i}\rho

K{\varOmega_{en}}\varepsilon \sqrt {We} - \rho

{K^2}\varepsilon We + \frac{{\rho K{\varOmega_s}\varepsilon

\sqrt {We} }}{2},}\\ {\bar{{\mathsf{F}}} = \frac{{ - \rho

{K^2}{\varepsilon^2}We}}{4},}\\ {{\varOmega_{en}} = {{\rm

B}_2} + \textrm{i}K\sqrt {W{e_\textrm{l}}} +

\textrm{i}n{\varOmega_s}} \end{array}}\right\},\end{gather}for sinuous mode and

\begin{gather}

\overline {{\boldsymbol{\mathsf{A}}_{\boldsymbol{2}}}}

\overline{\boldsymbol{\eta } }= \left(

{\begin{array}{@{}ccccccc@{}} \ddots & \vdots & \vdots & \vdots

& \vdots & \vdots & {\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} \\

\cdots &{\overline {{{\mathsf{D}}_{ - 22}}} }&{\overline {{{\mathsf{G}}_{ - 1}}}

}&{\overline{{\mathsf{F}}}} & 0 & 0 & \cdots \\ \cdots &{\overline {{{\mathsf{E}}_{ -

2}}} }&{\overline {{{\mathsf{D}}_{ - 12}}} }&{\overline {{{\mathsf{G}}_0}}

}&{\overline{{\mathsf{F}}}} & 0 & \cdots \\ \cdots &{\overline{{\mathsf{F}}}}

&{\overline {{{\mathsf{E}}_{ - 1}}} }&{\overline {{{\mathsf{D}}_{02}}}

}&{\overline {{{\mathsf{G}}_1}} }&{\overline{{\mathsf{F}}}}& \cdots \\ \cdots

& 0 & {\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_0}} }&{\overline

{{{\mathsf{D}}_{12}}} }&{\overline {{{\mathsf{G}}_2}} }& \cdots \\ \cdots

& 0 & 0 &{\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_1}} }&{\overline

{{{\mathsf{D}}_{22}}} }& \cdots \\

{\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} &

\vdots & \vdots & \vdots & \vdots & \vdots & \ddots

\end{array}} \right)\left( {\begin{array}{@{}c@{}} \vdots

\\ {\overline {{\eta_{_{-2}}}} }\\ {\overline {{\eta_{_{-1}}}} }\\

{\overline {{\eta_{_0}}} }\\ {\overline {{\eta_{_1}}}

}\\ {\overline {{\eta_{_2}}} }\\ \vdots \end{array}} \right) =

{\boldsymbol{0}},\end{gather}

\begin{gather}

\overline {{\boldsymbol{\mathsf{A}}_{\boldsymbol{2}}}}

\overline{\boldsymbol{\eta } }= \left(

{\begin{array}{@{}ccccccc@{}} \ddots & \vdots & \vdots & \vdots

& \vdots & \vdots & {\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} \\

\cdots &{\overline {{{\mathsf{D}}_{ - 22}}} }&{\overline {{{\mathsf{G}}_{ - 1}}}

}&{\overline{{\mathsf{F}}}} & 0 & 0 & \cdots \\ \cdots &{\overline {{{\mathsf{E}}_{ -

2}}} }&{\overline {{{\mathsf{D}}_{ - 12}}} }&{\overline {{{\mathsf{G}}_0}}

}&{\overline{{\mathsf{F}}}} & 0 & \cdots \\ \cdots &{\overline{{\mathsf{F}}}}

&{\overline {{{\mathsf{E}}_{ - 1}}} }&{\overline {{{\mathsf{D}}_{02}}}

}&{\overline {{{\mathsf{G}}_1}} }&{\overline{{\mathsf{F}}}}& \cdots \\ \cdots

& 0 & {\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_0}} }&{\overline

{{{\mathsf{D}}_{12}}} }&{\overline {{{\mathsf{G}}_2}} }& \cdots \\ \cdots

& 0 & 0 &{\overline{{\mathsf{F}}}}&{\overline {{{\mathsf{E}}_1}} }&{\overline

{{{\mathsf{D}}_{22}}} }& \cdots \\

{\mathinner{\mkern2mu\raise1pt\hbox{.}\mkern2mu

\raise4pt\hbox{.}\mkern2mu\raise7pt\hbox{.}\mkern1mu}} &

\vdots & \vdots & \vdots & \vdots & \vdots & \ddots

\end{array}} \right)\left( {\begin{array}{@{}c@{}} \vdots

\\ {\overline {{\eta_{_{-2}}}} }\\ {\overline {{\eta_{_{-1}}}} }\\

{\overline {{\eta_{_0}}} }\\ {\overline {{\eta_{_1}}}

}\\ {\overline {{\eta_{_2}}} }\\ \vdots \end{array}} \right) =

{\boldsymbol{0}},\end{gather}

\begin{gather}\begin{array}{@{}c@{}}

\overline {{{\mathsf{D}}_{n2}}} = Oh({K^2} + L_n^2)({\varOmega

_{en}} + 2Oh{K^\textrm{2}})\coth (K) -

4O{h^2}{K^3}{L_n}\coth ({L_n}) + {K^3}\\ + \rho

\varOmega _{en}^2 + 2\textrm{i}\rho K{\varOmega _{en}}\sqrt

{We} - \rho {K^2}We - \dfrac{{\rho {k^2}{\varepsilon

^2}We}}{2} \end{array}\end{gather}

\begin{gather}\begin{array}{@{}c@{}}

\overline {{{\mathsf{D}}_{n2}}} = Oh({K^2} + L_n^2)({\varOmega

_{en}} + 2Oh{K^\textrm{2}})\coth (K) -

4O{h^2}{K^3}{L_n}\coth ({L_n}) + {K^3}\\ + \rho

\varOmega _{en}^2 + 2\textrm{i}\rho K{\varOmega _{en}}\sqrt

{We} - \rho {K^2}We - \dfrac{{\rho {k^2}{\varepsilon

^2}We}}{2} \end{array}\end{gather}

for varicose mode.

In (2.9) and (2.11), ![]() ${\varOmega _{en}} = {\omega _{en}}/{(\sigma /{\rho _l}{a^3})^{1/2}}$ is the frequency,

${\varOmega _{en}} = {\omega _{en}}/{(\sigma /{\rho _l}{a^3})^{1/2}}$ is the frequency, ![]() $K = ka$ is the wavenumber,

$K = ka$ is the wavenumber, ![]() ${L_n} = \sqrt {{K^2} + {\varOmega _{en}}/O{h_n}} $ and

${L_n} = \sqrt {{K^2} + {\varOmega _{en}}/O{h_n}} $ and ![]() ${{\rm B}_2} = {\beta _2}/{(\sigma /{\rho _l}{a^3})^{1/2}}$. The Ohnesorge number is defined as

${{\rm B}_2} = {\beta _2}/{(\sigma /{\rho _l}{a^3})^{1/2}}$. The Ohnesorge number is defined as ![]() $Oh = \mu /{({\rho _\textrm{l}}a\sigma )^{1/2}}$, denoting the ratio of viscous forces to surface tension forces. The gas, liquid and relative Weber numbers are defined as

$Oh = \mu /{({\rho _\textrm{l}}a\sigma )^{1/2}}$, denoting the ratio of viscous forces to surface tension forces. The gas, liquid and relative Weber numbers are defined as ![]() $W{e_g} = {\rho _g}U_{g,0}^2a/\sigma $,

$W{e_g} = {\rho _g}U_{g,0}^2a/\sigma $, ![]() $W{e_l} = {\rho _l}U_l^2a/\sigma$ and

$W{e_l} = {\rho _l}U_l^2a/\sigma$ and ![]() $We = {\rho _l}U_0^2a/\sigma$, respectively. Here

$We = {\rho _l}U_0^2a/\sigma$, respectively. Here ![]() $\rho = {\rho _g}/{\rho _l}$ is the density ratio between the gas and liquid phases,

$\rho = {\rho _g}/{\rho _l}$ is the density ratio between the gas and liquid phases, ![]() $\varepsilon = \mathrm{\Delta }U/{U_0}$ is the oscillation amplitude and

$\varepsilon = \mathrm{\Delta }U/{U_0}$ is the oscillation amplitude and ![]() ${\varOmega _s} = {\omega _s}/{(\sigma /{\rho _l}{a^3})^{1/2}}$ is the oscillation frequency.

${\varOmega _s} = {\omega _s}/{(\sigma /{\rho _l}{a^3})^{1/2}}$ is the oscillation frequency.

The spatial growth rate was obtained by solving the dispersion equations. The present theoretical model was simplified to agree with that established by Li (Reference Li1993), who used the Reynolds number Re to study the effect of viscosity. The liquid sheet moved and the gas was static. In the present study, the Ohnesorge, Weber and Reynolds numbers satisfied ![]() $Oh = {{\sqrt {W{e_l}} } / {Re}}$. The results obtained by the present study were compared with those of Li (Reference Li1993). As shown in figure 5, these results were in accord with those of Li (Reference Li1993); the alteration of the reference system in the present study was rational. Meanwhile, according to Li (Reference Li1993), the results obtained by the spatial mode were close to those obtained by the temporal mode; therefore, the effect of physical parameters on the instability is not discussed here.

$Oh = {{\sqrt {W{e_l}} } / {Re}}$. The results obtained by the present study were compared with those of Li (Reference Li1993). As shown in figure 5, these results were in accord with those of Li (Reference Li1993); the alteration of the reference system in the present study was rational. Meanwhile, according to Li (Reference Li1993), the results obtained by the spatial mode were close to those obtained by the temporal mode; therefore, the effect of physical parameters on the instability is not discussed here.

Figure 5. Current results compared with those of Li (Reference Li1993). (![]() $We = 1000$,

$We = 1000$, ![]() $O{h_o} = \sqrt {We} /Re$,

$O{h_o} = \sqrt {We} /Re$, ![]() $\rho = 0.0013$,

$\rho = 0.0013$, ![]() ${U_{g,\textrm{0}}} = \textrm{0}$,

${U_{g,\textrm{0}}} = \textrm{0}$, ![]() $\mathrm{\Delta }U = \textrm{0}$.)

$\mathrm{\Delta }U = \textrm{0}$.)

Moreover, the schematics of surface wave induced by classical K–H instability (when ![]() $\mathrm{\Delta }U = 0$), oscillatory K–H instability (K–H unstable region of Jia et al. (Reference Jia, Xie, Yang, Fu and Cui2019)) and parametric instability (parametric unstable region of Jia et al. (Reference Jia, Xie, Yang, Fu and Cui2019)) are given in supplementary movies 1, 2 and 3, respectively, available at https://doi.org/10.1017/jfm.2023.19.

$\mathrm{\Delta }U = 0$), oscillatory K–H instability (K–H unstable region of Jia et al. (Reference Jia, Xie, Yang, Fu and Cui2019)) and parametric instability (parametric unstable region of Jia et al. (Reference Jia, Xie, Yang, Fu and Cui2019)) are given in supplementary movies 1, 2 and 3, respectively, available at https://doi.org/10.1017/jfm.2023.19.

2.3. Methods of measuring oscillations

Figure 6 shows the two microphones used to measure acoustic oscillations at two different points in the gas tube; the acoustic field in the tubes could then be calculated using the method of Poinsot et al. (Reference Poinsot, Le Chatelier, Candel and Esposito1986). In figure 6, ![]() ${l_\textrm{1}}$,

${l_\textrm{1}}$, ![]() ${l_\textrm{2}}$,

${l_\textrm{2}}$, ![]() ${l_\textrm{3}}$ and

${l_\textrm{3}}$ and ![]() ${l_\textrm{4}}$ represent the distances between microphone 1 and the loudspeaker, microphone 2 and microphone 1, the entrance of the gas nozzle and microphone 2 and the length of the gas nozzle, respectively. The resonant frequency changes with the pipe length. At resonant frequencies, the oscillating amplitudes at the gas nozzle exit are large, which benefits the atomization experiment, so the resonant conditions are chosen in the present study. The pipe lengths and their resonant frequencies are shown in table 1.

${l_\textrm{4}}$ represent the distances between microphone 1 and the loudspeaker, microphone 2 and microphone 1, the entrance of the gas nozzle and microphone 2 and the length of the gas nozzle, respectively. The resonant frequency changes with the pipe length. At resonant frequencies, the oscillating amplitudes at the gas nozzle exit are large, which benefits the atomization experiment, so the resonant conditions are chosen in the present study. The pipe lengths and their resonant frequencies are shown in table 1.

Figure 6. Schematic of measuring oscillations.

Table 1. Lengths of pipe at different frequencies.

A hot wire was used to measure gas velocity oscillations at the nozzle exit. The velocity measured by the hot wire corresponded to the acoustic field measured by the microphones, so the gas velocity at the nozzle exit could be calculated by the acoustic field during the atomization experiments.

First, the form of the sound field can be set as

where ![]() ${A_ + }$,

${A_ + }$, ![]() ${A_ - }$,

${A_ - }$, ![]() ${k_{s + }}$,

${k_{s + }}$, ![]() ${k_{s - }}$ and

${k_{s - }}$ and ![]() ${\omega _s}$ are the amplitudes of the acoustic wave in the positive and negative directions, the wavenumbers of the acoustic wave in the positive and negative directions and the acoustic frequency, respectively. The wavenumbers were obtained as follows:

${\omega _s}$ are the amplitudes of the acoustic wave in the positive and negative directions, the wavenumbers of the acoustic wave in the positive and negative directions and the acoustic frequency, respectively. The wavenumbers were obtained as follows:

where ![]() ${k_s} = {\omega _s}/c$ and M is the Mach number of the mean gas velocity. In the present study, the mean gas velocity was lower than 10 m s−1. Mach number

${k_s} = {\omega _s}/c$ and M is the Mach number of the mean gas velocity. In the present study, the mean gas velocity was lower than 10 m s−1. Mach number ![]() $M \ll \textrm{1}$, so

$M \ll \textrm{1}$, so

Therefore, the sound pressure at the microphone measuring position can be expressed as

where

Using the equation set

where

the amplitudes of the acoustic wave were obtained, and then the acoustic field could be obtained. The velocity and pressure oscillations at the nozzle exit could be calculated. This velocity oscillation matched the results obtained with the hot wire.

This method was also used to find the relative sensitivity of the two microphones at different frequencies. The sensitivities of microphone 1 and microphone 2 were ![]() ${G_\textrm{1}}$ and

${G_\textrm{1}}$ and ![]() ${G_\textrm{2}}$, respectively. The signals found the first and the second time are expressed by prime and double prime, respectively. First, microphones 1 and 2 were used to measure the voltage signals at points a and b, respectively. The second time, the two microphones were switched at the same frequency. The sound pressure amplitude can be expressed as

${G_\textrm{2}}$, respectively. The signals found the first and the second time are expressed by prime and double prime, respectively. First, microphones 1 and 2 were used to measure the voltage signals at points a and b, respectively. The second time, the two microphones were switched at the same frequency. The sound pressure amplitude can be expressed as

where V is the voltage measured by the microphone and p is the sound pressure. Because the form of the acoustic field was certain, the sound pressures satisfied

By substituting equations (2.19) and (2.20) into (2.21), the sensitivities of the microphones can be obtained:

The sensitivity of microphone 1 was 0.65 mV Pa−1; the sensitivity of microphone 2 was obtained according to (2.22). In this study, the frequency range used for the experiment was 100–177 Hz, so a frequency range of 90–180 Hz was selected to calculate the sensitivity, as shown in figure 7. The fitting formula can be obtained as follows:

\begin{align}\hat{G} &={-} 3.82 \times {10^{ - 12}}f_s^5 + 2.87 \times {10^{ - 9}}f_s^4 - 8.54 \times {10^{ - 7}}f_s^3\nonumber\\ &\quad + 1.28 \times {10^{ - 4}}f_s^2 - 0.0098{f_s} + 0.853,\end{align}

\begin{align}\hat{G} &={-} 3.82 \times {10^{ - 12}}f_s^5 + 2.87 \times {10^{ - 9}}f_s^4 - 8.54 \times {10^{ - 7}}f_s^3\nonumber\\ &\quad + 1.28 \times {10^{ - 4}}f_s^2 - 0.0098{f_s} + 0.853,\end{align}

where ![]() $\hat{G} = {G_\textrm{2}}/{G_\textrm{1}}$ is the sensitivity ratio between microphone 2 and microphone 1.

$\hat{G} = {G_\textrm{2}}/{G_\textrm{1}}$ is the sensitivity ratio between microphone 2 and microphone 1.

Figure 7. Ratio of microphone sensitivities.

To conduct the experimental work in the present study, acoustic oscillations at frequencies of 100, 121, 142, 161 and 177 Hz were adopted. For example, signals obtained at 100 Hz are shown in figure 8. The primary data are shown in figure 8(a). By substituting the sensitivities, the pressures and velocities can be obtained. Extracting the dominant mode using fast Fourier transform (FFT), the pressures and velocities of the dominant mode were obtained, as shown in figure 8(b).

Figure 8. (a) Primary data and (b) pressures and velocities of dominant modes obtained from microphones and hot wire.

Considering (2.12), the gas velocity at the nozzle exit can be obtained from the acoustic field calculated from the signals obtained by the microphones as follows:

The velocity obtained from (2.24) was compared with the velocity obtained by the hot wire (figure 8b). The gas velocity at the nozzle exit was

and the gas velocity obtained by the hot wire could be fitted with the gas velocity oscillation calculated from (2.24) as follows:

As shown in figure 9, the fitting formulas shown in (2.26) and (2.27) accord well with the measured gas velocity. Adopting this method, the gas velocity at the nozzle exit could be calculated from the microphone signal. The relationship between the root mean squares before and after FFT is displayed in figure 10. The root mean squares represent the effective value of the gas velocity, including the effect of the mean and oscillating velocity. The relationship can be fitted as

Figure 9. Relationship between gas velocity measured by hot wire and gas velocity oscillation amplitude calculated using (2.24).

Figure 10. Relationship between root mean squares before and after FFT ![]() $(\,f_s = \textrm{100}\ \textrm{Hz)}$.

$(\,f_s = \textrm{100}\ \textrm{Hz)}$.

The fitting expression corresponded well with the measured results, verifying the consistency of the method used at different oscillating amplitudes.

2.4. Analytical methods of image sequence

2.4.1. Proper orthogonal decomposition

Proper orthogonal decomposition (POD) is an effective method to extract the wavelength, amplitude and wave frequency of a liquid film (Arienti & Soteriou Reference Arienti and Soteriou2009; Kang, Li & Mao Reference Kang, Li and Mao2018). The POD theory is described briefly below.

A high-speed camera obtained 8-bit images, the matrix consisting of the grey level of each pixel. An image presents the transient information at time t, so the image ![]() $T(t)$ can be expressed as

$T(t)$ can be expressed as

where ![]() ${a^0},{a^1},{a^2}, \ldots $ are time coefficients at time t and

${a^0},{a^1},{a^2}, \ldots $ are time coefficients at time t and ![]() ${\varphi ^0},{\varphi ^1},{\varphi ^2}, \ldots $ are proper orthogonal modes (POMs). For a sequence of images, N is the quantity of the images and

${\varphi ^0},{\varphi ^1},{\varphi ^2}, \ldots $ are proper orthogonal modes (POMs). For a sequence of images, N is the quantity of the images and ![]() $R \times C$ is the resolution of the images. Each image can be described by a matrix

$R \times C$ is the resolution of the images. Each image can be described by a matrix ![]() ${x^r}$ with dimension

${x^r}$ with dimension ![]() $RC \times 1$, so the image sequence can be expressed as a matrix with dimension

$RC \times 1$, so the image sequence can be expressed as a matrix with dimension ![]() $RC \times N$, where

$RC \times N$, where ![]() ${x^r}$ represents the matrix of the rth image. The matrix can be expressed as

${x^r}$ represents the matrix of the rth image. The matrix can be expressed as

\begin{equation}

\boldsymbol{\mathsf{X}} = [{\boldsymbol{x}^1} \cdots {\boldsymbol{x}^N}]

= \left[ {\begin{array}{*{20}{c}} {{\mathsf{x}}_{1,1}^1}& \cdots

&{{\mathsf{x}}_{1,1}^N}\\ \vdots & \vdots & \vdots \\ {{\mathsf{x}}_{R,1}^1}&

\cdots &{{\mathsf{x}}_{R,1}^N}\\ {{\mathsf{x}}_{1,2}^1}& \cdots &{{\mathsf{x}}_{1,2}^N}\\

\vdots & \vdots & \vdots \\ {{\mathsf{x}}_{R,2}^1}& \cdots

&{{\mathsf{x}}_{R,2}^N}\\ \vdots & \vdots & \vdots \\ {{\mathsf{x}}_{R,C}^1}&

\cdots &{{\mathsf{x}}_{R,C}^N} \end{array}}\right].\end{equation}

\begin{equation}

\boldsymbol{\mathsf{X}} = [{\boldsymbol{x}^1} \cdots {\boldsymbol{x}^N}]

= \left[ {\begin{array}{*{20}{c}} {{\mathsf{x}}_{1,1}^1}& \cdots

&{{\mathsf{x}}_{1,1}^N}\\ \vdots & \vdots & \vdots \\ {{\mathsf{x}}_{R,1}^1}&

\cdots &{{\mathsf{x}}_{R,1}^N}\\ {{\mathsf{x}}_{1,2}^1}& \cdots &{{\mathsf{x}}_{1,2}^N}\\

\vdots & \vdots & \vdots \\ {{\mathsf{x}}_{R,2}^1}& \cdots

&{{\mathsf{x}}_{R,2}^N}\\ \vdots & \vdots & \vdots \\ {{\mathsf{x}}_{R,C}^1}&

\cdots &{{\mathsf{x}}_{R,C}^N} \end{array}}\right].\end{equation}

Therefore, the average image is

\begin{equation}\bar{\boldsymbol{x}} = \frac{1}{N}\sum\limits_{r = 1}^N {{\boldsymbol{x}^r}} ,\end{equation}

\begin{equation}\bar{\boldsymbol{x}} = \frac{1}{N}\sum\limits_{r = 1}^N {{\boldsymbol{x}^r}} ,\end{equation}and the matrix of pulsating quantity is

Building up the matrix,

The eigenvectors ![]() ${A^i}$ and eigenvalues

${A^i}$ and eigenvalues ![]() ${\lambda ^i}$ can be obtained:

${\lambda ^i}$ can be obtained:

The eigenvalues ![]() ${\lambda ^i}$ are sorted in descending order:

${\lambda ^i}$ are sorted in descending order:

so that the energy ratio of each POM is

\begin{equation}{E_i} = \frac{{{\lambda ^i}}}{{\sum\limits_{j = 1}^N {{\lambda ^j}} }}.\end{equation}

\begin{equation}{E_i} = \frac{{{\lambda ^i}}}{{\sum\limits_{j = 1}^N {{\lambda ^j}} }}.\end{equation}Then, the ith POM can be obtained:

\begin{equation}{\boldsymbol{\varphi} ^i} =

\frac{{\sum\limits_{n = 1}^N {A_n^i{\boldsymbol{x}^n}}

}}{{\left\|{\sum\limits_{n = 1}^N {A_n^i{\boldsymbol{x}^n}} }

\right\|}}.\end{equation}

\begin{equation}{\boldsymbol{\varphi} ^i} =

\frac{{\sum\limits_{n = 1}^N {A_n^i{\boldsymbol{x}^n}}

}}{{\left\|{\sum\limits_{n = 1}^N {A_n^i{\boldsymbol{x}^n}} }

\right\|}}.\end{equation}

2.4.2. Growth rate measurement method

(a) For steady gas flow

A typical waveform in the experimental study is shown in figure 11. When the surface wave grew in this form, the surface wave was a travelling wave, and the linear theory was an effective measure of the growth rate. When the gas velocity oscillation amplitude was zero, the displacement of each point on the surface could be expressed as

where ![]() $k = {k_r} + \textrm{i}{k_i}$,

$k = {k_r} + \textrm{i}{k_i}$, ![]() ${k_r}$ is the wavenumber,

${k_r}$ is the wavenumber, ![]() ${k_i}$ is the opposite number of the spatial growth rate and

${k_i}$ is the opposite number of the spatial growth rate and ![]() $\beta = \textrm{i}{\beta _i}$ is the frequency of the surface wave. The envelopes of the surface wave are

$\beta = \textrm{i}{\beta _i}$ is the frequency of the surface wave. The envelopes of the surface wave are

and

Figure 11. (a–h) Surface wave development in oscillation period (1988 fps; ![]() ${f_s} = 142\ \textrm{Hz}$; concentration of glycerin–water solution, 60 wt%; microphone 1,

${f_s} = 142\ \textrm{Hz}$; concentration of glycerin–water solution, 60 wt%; microphone 1, ![]() ${V_1} = 3040.64\ \textrm{mV}$; microphone 2,

${V_1} = 3040.64\ \textrm{mV}$; microphone 2, ![]() ${V_2} = \textrm{1585}\textrm{.01}\ \textrm{mV}$; liquid flow rate, 0.1103 m3 h−1).

${V_2} = \textrm{1585}\textrm{.01}\ \textrm{mV}$; liquid flow rate, 0.1103 m3 h−1).

Therefore, the spatial growth rate can be obtained from

To verify the effectiveness of this method, a standard, spatially growing wave was plotted, and the envelopes obtained are shown in figure 12(a). The measured growth rate is shown in figure 12(b). The standard wave is given as ![]() $k = (500 - 120i)\ {\textrm{m}^{ - 1}}$ and

$k = (500 - 120i)\ {\textrm{m}^{ - 1}}$ and ![]() $2a = {10^{ - 3}}\ \textrm{m}$, and the measured growth rate is

$2a = {10^{ - 3}}\ \textrm{m}$, and the measured growth rate is ![]() $\textrm{(}122.78 \pm 0.52\textrm{)}\ {\textrm{m}^{ - 1}}$. The error between the measured and given growth rates was smaller than 3 %, confirming the effectiveness of this method.

$\textrm{(}122.78 \pm 0.52\textrm{)}\ {\textrm{m}^{ - 1}}$. The error between the measured and given growth rates was smaller than 3 %, confirming the effectiveness of this method.

Figure 12. (a) Upper and lower envelopes of standard wave and (b) fitted curve of growth rate for oscillating gas flow.

(b) For oscillating gas flow

The spatial variation of the surface displacement could not be expressed as (2.38) and (2.39) but with the form of (A29). The simplest form was adopted, as follows:

According to the experimental phenomenon, ![]() $\beta ={-} {\omega _s}$; thus, (2.44) and (2.45) can be simplified as

$\beta ={-} {\omega _s}$; thus, (2.44) and (2.45) can be simplified as

Therefore, the envelopes are

and

It was found that (2.50) has the same form as (2.42); therefore, (2.43) could also be used to obtain the growth rate. (Envelopes are shown in figure 13; the measured growth rate was ![]() $123.17 \pm 0.84\ {\textrm{m}^{ - 1}}$.) The error between this growth rate and the given growth rate of

$123.17 \pm 0.84\ {\textrm{m}^{ - 1}}$.) The error between this growth rate and the given growth rate of ![]() $120\ {\textrm{m}^{ - 1}}$ was less than 4 %, confirming the effectiveness of this method for measuring the spatial growth rate.

$120\ {\textrm{m}^{ - 1}}$ was less than 4 %, confirming the effectiveness of this method for measuring the spatial growth rate.

Figure 13. Envelopes when gas velocity oscillation exists.

3. Results and discussion

3.1. Growth rate

This section examines the measured growth rate of the surface wave and the effects of oscillation, flow and physical property parameters on the instability. First, the destabilization of the liquid sheet in steady gas flow was studied for comparison. The effective range of the growth rate measurement method could also be obtained. In this range, the growth rate of the liquid sheet in an oscillating gas flow was studied in detail.

3.1.1. Instability phenomenon in steady and oscillating gas flow

According to § 2.2, the gas velocity was

For steady gas flow, ![]() $\Delta U = 0$, i.e.

$\Delta U = 0$, i.e. ![]() ${U_g} = {U_{g,0}} = {U_l} + {U_0}$. The liquid and gas Weber numbers were defined as

${U_g} = {U_{g,0}} = {U_l} + {U_0}$. The liquid and gas Weber numbers were defined as ![]() $W{e_l} = {\rho _l}U_l^2a/\sigma $ and

$W{e_l} = {\rho _l}U_l^2a/\sigma $ and ![]() $W{e_g} = {\rho _g}U_g^2a/\sigma $, respectively. Figure 14 displays an image sequence of the liquid sheet in the presence of steady gas flow frame by frame at 1693 fps; the periodicity of the surface wave was apparent. Although there was no forcing oscillation, a dominant wavelength could also be observed. The disturbance with this wavelength led to the breakup of the liquid sheet. Therefore, the theory postulated in § 2.2 was suitable for analysing the growth of the surface wave for conditions such as those in figure 14.

$W{e_g} = {\rho _g}U_g^2a/\sigma $, respectively. Figure 14 displays an image sequence of the liquid sheet in the presence of steady gas flow frame by frame at 1693 fps; the periodicity of the surface wave was apparent. Although there was no forcing oscillation, a dominant wavelength could also be observed. The disturbance with this wavelength led to the breakup of the liquid sheet. Therefore, the theory postulated in § 2.2 was suitable for analysing the growth of the surface wave for conditions such as those in figure 14.

Figure 14. (a–j) Surface wave of liquid sheet in the presence of steady gas flow. (Liquid was deionized water; gas was air; ![]() ${U_l} = 1.16\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.16\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() ${U_{g,0}} = 7.83\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_{g,0}} = 7.83\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() ${\rho _l} = 998\ \textrm{kg}\ {\textrm{m}^{ - 3}}$,

${\rho _l} = 998\ \textrm{kg}\ {\textrm{m}^{ - 3}}$, ![]() ${\rho _g} = 1.2\ \textrm{kg}\ {\textrm{m}^{ - 3}}$,

${\rho _g} = 1.2\ \textrm{kg}\ {\textrm{m}^{ - 3}}$, ![]() $a = 0.0002\ \textrm{m}$,

$a = 0.0002\ \textrm{m}$, ![]() $\mu = 0.96\ \textrm{mPa}\ \textrm{s}$,

$\mu = 0.96\ \textrm{mPa}\ \textrm{s}$, ![]() $\sigma = 0.0689\ \textrm{N}\ {\textrm{m}^{ - 1}}$,

$\sigma = 0.0689\ \textrm{N}\ {\textrm{m}^{ - 1}}$, ![]() $W{e_l} = 3.898$,

$W{e_l} = 3.898$, ![]() $W{e_g} = 0.199$,

$W{e_g} = 0.199$, ![]() $R{e_l} = 241$,

$R{e_l} = 241$, ![]() $\rho = 0.0012$.)

$\rho = 0.0012$.)

The method POD is also useful for analysing an image sequence with periodicity, so it was applied to investigate the surface wave in figure 14. A total of 401 sequential images were used for POD, and the results are shown in figure 15. Modes 1 and 2 were the dominant modes (figure 15b) with the same dominant frequency (figure 15e,f) of 186.2. In figure 14, a period includes approximately nine images, indicating that the frequency is approximately 188 Hz. These two very close values verify the validity of POD in obtaining the dominant modes. In addition, the surface wave grew exponentially in the axial direction, which was close to the ideal model in § 2.4.2. However, the disturbance amplitude nearly reached a maximum when the liquid sheet was relatively far from the nozzle. Thus, the growth rate measurement was conducted in the range where the disturbance amplitude was not too great.

Figure 15. (a) Envelopes of surface wave, and results of POD with steady gas flow: (b) POD energy distribution, (c) mode 1, (d) mode 2, (e) frequency spectrum of mode 1 and (f) frequency spectrum of mode 1. (Working conditions same as figure 14.)

When gas velocity oscillation was present, non-dimensional frequency ![]() ${\varOmega _{s2}} = {\omega _s}a/{U_l}$ and amplitude

${\varOmega _{s2}} = {\omega _s}a/{U_l}$ and amplitude ![]() ${\varepsilon _2} = \Delta U/{U_{g,0}}$ were defined to describe the gas flow oscillations. As shown in figure 16, the surface wave was more regular (the dominant wavelength and frequency were more apparent than in figure 14). The dominant frequency was the same as the gas oscillating frequency (142 Hz), obtained from the POD results in figure 17. Moreover, the POD results also showed that the energy ratio in the first two modes was the highest, exceeding 35 %. This result meant that the first two modes dominated the surface wave destabilization. The leading role of the first two modes in this condition was stronger than that in the conditions of figure 15, coinciding with the intuitive results obtained from figure 16.

${\varepsilon _2} = \Delta U/{U_{g,0}}$ were defined to describe the gas flow oscillations. As shown in figure 16, the surface wave was more regular (the dominant wavelength and frequency were more apparent than in figure 14). The dominant frequency was the same as the gas oscillating frequency (142 Hz), obtained from the POD results in figure 17. Moreover, the POD results also showed that the energy ratio in the first two modes was the highest, exceeding 35 %. This result meant that the first two modes dominated the surface wave destabilization. The leading role of the first two modes in this condition was stronger than that in the conditions of figure 15, coinciding with the intuitive results obtained from figure 16.

Figure 16. (a–i) Destabilization of liquid sheet in the presence of oscillating gas flow. (Liquid is deionized water; gas is oscillating gas flow produced by gas flow; ![]() ${U_l} = 1.84\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.84\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() ${U_{g,0}} = 6.\textrm{614}\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_{g,0}} = 6.\textrm{614}\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() $\Delta U = \textrm{8}\textrm{.639}\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

$\Delta U = \textrm{8}\textrm{.639}\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() ${\rho _l} = 998\ \textrm{kg}\ {\textrm{m}^{ - 3}}$,

${\rho _l} = 998\ \textrm{kg}\ {\textrm{m}^{ - 3}}$, ![]() ${\rho _g} = 1.2\ \textrm{kg}\ {\textrm{m}^{ - 3}}$,

${\rho _g} = 1.2\ \textrm{kg}\ {\textrm{m}^{ - 3}}$, ![]() $a = 0.0002\ \textrm{m}$,

$a = 0.0002\ \textrm{m}$, ![]() $\mu = 0.96\ \textrm{mPa}\ \textrm{s}$,

$\mu = 0.96\ \textrm{mPa}\ \textrm{s}$, ![]() $\sigma = 0.0689\ \textrm{N}\ {\textrm{m}^{ - 1}}$,

$\sigma = 0.0689\ \textrm{N}\ {\textrm{m}^{ - 1}}$, ![]() $W{e_l} = 9.81$,

$W{e_l} = 9.81$, ![]() $W{e_g} = 0.143$,

$W{e_g} = 0.143$, ![]() $R{e_l} = 383$,

$R{e_l} = 383$, ![]() $\rho = 0.0012$,

$\rho = 0.0012$, ![]() ${\varOmega _{s2}} = 0.0154$,

${\varOmega _{s2}} = 0.0154$, ![]() ${\varepsilon _2} = 1.3062$.)

${\varepsilon _2} = 1.3062$.)

Figure 17. (a) Envelopes of surface wave, and results of POD with oscillating gas flow: (b) energy distribution, (c) mode 1, (d) mode 2, (e) frequency spectrum of mode 1 and (f) frequency spectrum of mode 2. (Working conditions same as figure 16.)

Note that the gas oscillation not only made the wavelength and frequency of the surface wave more regular but also dramatically influenced the form of spatially growing surface waves. In figure 17(a), in addition to exponential growth, oscillatory growth was also found, which was significantly different from figure 15(a). Moreover, this oscillatory growth resulted in oscillating spatial envelopes. Physically, when the gas flow was steady, the aerodynamic force on the liquid sheet was also steady, according to linear theory. However, when the gas flow was oscillatory, the aerodynamic force was also oscillatory. When the aerodynamic force was larger in the positive cycle, the growth of the disturbance accelerated; when the aerodynamic force was lower in the negative cycle, the growth of the disturbance slowed down. Therefore, the growth of the surface wave was oscillatory during several gas flow oscillating periods. Furthermore, due to the gas oscillation, the growth rate might not be constant but a function of time, which is characteristic of the oscillatory K–H instability. However, because the dominant frequencies of the surface wave and the gas oscillation were the same, the growth rate could be obtained using the method in § 2.4.2 (equation (2.50)), i.e. the growth rate was constant. The envelopes in figure 17(a) were qualitatively in accord with those in figure 13, which to some extent verified the theoretical basis presented in § 2.2 and Appendix A. Note that when the working conditions changed, the form and characteristics of the surface wave could also change. A detailed discussion of the waveform is presented in § 3.2.

3.1.2. Growth rate in steady gas flow

The method used in § 2.4.2(a) was utilized when the gas flow was steady. The envelopes of the liquid sheets in the images were abstracted to measure the growth rate, and the results are depicted in figure 18. The theoretical curve was obtained from (2.8). Because there was an apparent dominant wavelength of the surface wave, the growth rate corresponding to the theoretically dominant wavenumber (i.e. maximum growth rate) was regarded as the theoretical growth rate. The experimental and theoretical results agreed well when ![]() $W{e_g} < \textrm{0}\textrm{.3}$. Parameter

$W{e_g} < \textrm{0}\textrm{.3}$. Parameter ![]() $W{e_g}$ represents the ratio between the aerodynamic force and the surface tension. Here, the surface tension was constant, so

$W{e_g}$ represents the ratio between the aerodynamic force and the surface tension. Here, the surface tension was constant, so ![]() $W{e_g}$ represents the aerodynamic force. Aerodynamic force was the driving power of K–H instability, so with increased

$W{e_g}$ represents the aerodynamic force. Aerodynamic force was the driving power of K–H instability, so with increased ![]() $W{e_g}$, the theoretical growth rate presented an approximately linear growth. However, the measured growth rate reached a maximum when

$W{e_g}$, the theoretical growth rate presented an approximately linear growth. However, the measured growth rate reached a maximum when ![]() $W{e_g} > 0.32$.

$W{e_g} > 0.32$.

Figure 18. Theoretical and measured growth rates in steady gas flow. (Liquid is deionized water; gas is air; full line is theoretical prediction; error bars are experimental results; ![]() $W{e_l} = 3.898$,

$W{e_l} = 3.898$, ![]() $R{e_l} = 241$,

$R{e_l} = 241$, ![]() $\rho = 0.0012$.)

$\rho = 0.0012$.)

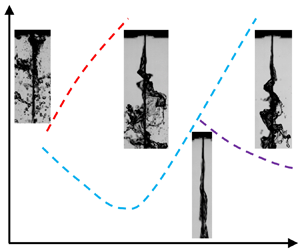

The change rule of the growth rate can be explained qualitatively. As shown in figure 19, the wavelength and the breakup length decreased with increasing ![]() $W{e_g}$, indicating an enhancement of the instability. However, as shown in figure 19(a,b,e,f), the surface wave was regular when

$W{e_g}$, indicating an enhancement of the instability. However, as shown in figure 19(a,b,e,f), the surface wave was regular when ![]() $W{e_g} < 0.3$, and the surface wave was in the axial direction rather than spanwise (i.e. the surface wave was approximately two-dimensional), so the two-dimensional model adopted in § 2.2 was also tenable. However, when

$W{e_g} < 0.3$, and the surface wave was in the axial direction rather than spanwise (i.e. the surface wave was approximately two-dimensional), so the two-dimensional model adopted in § 2.2 was also tenable. However, when ![]() $W{e_g} > 0.3$, as shown in figure 19(c,d,g,h), the surface wave was disordered. There were spanwise surface waves on the liquid sheet, so the growth rate obtained from the two-dimensional theoretical model inevitably resulted in some error. Additionally, due to the nonlinear effect, the disturbance could not increase infinitely, and a shorter wavelength corresponded to a lower saturated displacement. As a result, although the destabilizing and atomization phenomenon in figure 19(d) is more intense than that in figure 19(c), the difference in the disturbance displacement was not distinct due to the small wavelength. The measuring method for the growth rate was based on the disturbance displacement, and this method loses efficacy when the atomization is relatively intense. In conclusion, it was atomization intensity that determined whether the growth rate measuring method could be used. The method was critical when the surface wave was regular, but the growth rate can reflect the atomization intensity. According to figure 18, this method was able to measure the growth rate when

$W{e_g} > 0.3$, as shown in figure 19(c,d,g,h), the surface wave was disordered. There were spanwise surface waves on the liquid sheet, so the growth rate obtained from the two-dimensional theoretical model inevitably resulted in some error. Additionally, due to the nonlinear effect, the disturbance could not increase infinitely, and a shorter wavelength corresponded to a lower saturated displacement. As a result, although the destabilizing and atomization phenomenon in figure 19(d) is more intense than that in figure 19(c), the difference in the disturbance displacement was not distinct due to the small wavelength. The measuring method for the growth rate was based on the disturbance displacement, and this method loses efficacy when the atomization is relatively intense. In conclusion, it was atomization intensity that determined whether the growth rate measuring method could be used. The method was critical when the surface wave was regular, but the growth rate can reflect the atomization intensity. According to figure 18, this method was able to measure the growth rate when ![]() $- {K_i} < 0.06$. Hereafter, for the condition of oscillating gas flow,

$- {K_i} < 0.06$. Hereafter, for the condition of oscillating gas flow, ![]() $- {K_i} < 0.06$ was satisfactory to guarantee the correctness of the measuring results.

$- {K_i} < 0.06$ was satisfactory to guarantee the correctness of the measuring results.

Figure 19. Destabilization of liquid sheet for different gas Weber numbers: (a) ![]() $W{e_g} = 0.0927$; (b)

$W{e_g} = 0.0927$; (b) ![]() $W{e_g} = 0.199$; (c)

$W{e_g} = 0.199$; (c) ![]() $W{e_g} = 0.453$; (d)

$W{e_g} = 0.453$; (d) ![]() $W{e_g} = 0.637$. Other parameters are same as figure 18. (e–h) Front views of (a–d), respectively: (e)

$W{e_g} = 0.637$. Other parameters are same as figure 18. (e–h) Front views of (a–d), respectively: (e) ![]() $W{e_g} = 0.0927$; (f)

$W{e_g} = 0.0927$; (f) ![]() $W{e_g} = 0.199$; (g)

$W{e_g} = 0.199$; (g) ![]() $W{e_g} = 0.453$; (h)

$W{e_g} = 0.453$; (h) ![]() $W{e_g} = 0.637$.

$W{e_g} = 0.637$.

3.1.3. Growth rate in oscillating gas flow

In this section, experimental and theoretical growth rates are compared in the presence of oscillating gas flow. The theoretical results were obtained according to (2.8). Experiments were conducted using deionized water and glycerol aqueous solutions at different concentrations, and the corresponding physical parameters are listed in table 2. The viscosity differences versus various concentrations were the most obvious; the differences in density and surface tension were also non-negligible. Hence, the effect of a single physical factor was difficult to study. In the present work, the liquid velocity was adjusted to guarantee a constant liquid Weber number ![]() $W{e_l}$.

$W{e_l}$.

Table 2. Physical parameters of water and glycerol aqueous solutions at different concentrations.

Due to the amplitude–frequency characteristics of the loudspeaker and the different acoustic field distributions at various frequencies in the tube, the relationship between the gas mean velocity and oscillation velocity also varied with oscillation frequency. Fitting the oscillating and mean velocity, the relationship was as follows:

\begin{equation}\left. {\begin{array}{*{20}{c@{}}} {\Delta U = 1.809{U_{g,0}} - 2.500,\quad 100\ \textrm{Hz,}}\\ {\Delta U = 2.000{U_{g,0}} - 4.445,\quad 121\ \textrm{Hz,}}\\ {\Delta U = 1.903{U_{g,0}} - 3.944,\quad 142\ \textrm{Hz,}}\\ {\Delta U ={-} 0.1978U_{g,0}^2 + 4.31765{U_{g,0}} - 11.44,\quad 161\ \textrm{Hz,}}\\ {\Delta U ={-} 0.3654U_{g,0}^2 + 6.6875{U_{g,0}} - 19.99,\quad 177\ \textrm{Hz}\textrm{.}} \end{array}} \right\}\end{equation}

\begin{equation}\left. {\begin{array}{*{20}{c@{}}} {\Delta U = 1.809{U_{g,0}} - 2.500,\quad 100\ \textrm{Hz,}}\\ {\Delta U = 2.000{U_{g,0}} - 4.445,\quad 121\ \textrm{Hz,}}\\ {\Delta U = 1.903{U_{g,0}} - 3.944,\quad 142\ \textrm{Hz,}}\\ {\Delta U ={-} 0.1978U_{g,0}^2 + 4.31765{U_{g,0}} - 11.44,\quad 161\ \textrm{Hz,}}\\ {\Delta U ={-} 0.3654U_{g,0}^2 + 6.6875{U_{g,0}} - 19.99,\quad 177\ \textrm{Hz}\textrm{.}} \end{array}} \right\}\end{equation}

The curves of the non-dimensional growth rate ![]() $- {K_i}$ versus increasing gas Weber number

$- {K_i}$ versus increasing gas Weber number ![]() $W{e_g}$ were theoretically computed and compared with the experimentally measured values, as plotted in figure 20. It is important to remember that the frequency of the surface wave was equal to the gas oscillating frequency. Then, the growth rate corresponding to the oscillation frequency should be chosen as the theoretical growth rate. This is different from the condition of steady gas flow (figure 18), i.e. the theoretical growth rate may not be the maximum. This phenomenon can be explained physically: gas velocity oscillation inevitably modulates the surface wave in addition to providing an oscillating basic flow, so the disturbance with a frequency equal to the gas velocity oscillation frequency is much larger than other disturbances in the initial unstable stage. Therefore, this disturbance was observed in the image sequence.

$W{e_g}$ were theoretically computed and compared with the experimentally measured values, as plotted in figure 20. It is important to remember that the frequency of the surface wave was equal to the gas oscillating frequency. Then, the growth rate corresponding to the oscillation frequency should be chosen as the theoretical growth rate. This is different from the condition of steady gas flow (figure 18), i.e. the theoretical growth rate may not be the maximum. This phenomenon can be explained physically: gas velocity oscillation inevitably modulates the surface wave in addition to providing an oscillating basic flow, so the disturbance with a frequency equal to the gas velocity oscillation frequency is much larger than other disturbances in the initial unstable stage. Therefore, this disturbance was observed in the image sequence.

Figure 20. Growth rate of solutions at different concentrations. (a) Deionized water: ![]() ${U_l} = 1.820\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.820\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() $R{e_l} = 378.4$,

$R{e_l} = 378.4$, ![]() $\rho \textrm{ = 0}\textrm{.0012}$,

$\rho \textrm{ = 0}\textrm{.0012}$, ![]() ${\varOmega _{s2}} = 0.0980$; (b) 20 % glycerol aqueous solution:

${\varOmega _{s2}} = 0.0980$; (b) 20 % glycerol aqueous solution: ![]() ${U_l} = 1.779\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.779\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() $R{e_l} = 211.8$,

$R{e_l} = 211.8$, ![]() $\rho = 0.00114$,

$\rho = 0.00114$, ![]() ${\varOmega _{s2}} = 0.1005$; (c) 40 % glycerol aqueous solution:

${\varOmega _{s2}} = 0.1005$; (c) 40 % glycerol aqueous solution: ![]() ${U_l} = 1.704\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.704\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() $R{e_l} = 93.7$,

$R{e_l} = 93.7$, ![]() $\rho = 0.00109$,

$\rho = 0.00109$, ![]() ${\varOmega _{s2}} = 0.1049$; (d) 60 % glycerol aqueous solution:

${\varOmega _{s2}} = 0.1049$; (d) 60 % glycerol aqueous solution: ![]() ${U_l} = 1.635\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.635\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() $R{e_l} = 31.6$,

$R{e_l} = 31.6$, ![]() $\rho = 0.00104$,

$\rho = 0.00104$, ![]() ${\varOmega _{s\textrm{2}}} = 0.1093$. (Full line is theoretical curves; error bars are measured results; gas is air;

${\varOmega _{s\textrm{2}}} = 0.1093$. (Full line is theoretical curves; error bars are measured results; gas is air; ![]() ${\rho _g} = \textrm{1}\textrm{.2}\ \textrm{kg}\ {\textrm{m}^{ - \textrm{3}}}$,

${\rho _g} = \textrm{1}\textrm{.2}\ \textrm{kg}\ {\textrm{m}^{ - \textrm{3}}}$, ![]() $a = 0.0002\ \textrm{m}$,

$a = 0.0002\ \textrm{m}$, ![]() ${f_s} = 142\ \textrm{Hz}$).

${f_s} = 142\ \textrm{Hz}$).

The effective gas Weber number ![]() $W{e_{g2}} = {\rho _g}(U_{g,0}^2 + \Delta {U^2}/2)a/\sigma$ is defined to represent the aerodynamic force. This Weber number reflects the effect of the mean and oscillating gas velocity and has two advantages:

$W{e_{g2}} = {\rho _g}(U_{g,0}^2 + \Delta {U^2}/2)a/\sigma$ is defined to represent the aerodynamic force. This Weber number reflects the effect of the mean and oscillating gas velocity and has two advantages:

(1) In the K–H unstable region, destabilization of the surface wave was determined by the effective aerodynamic force, as stated in early work by the authors (Jia et al. Reference Jia, Xie, Yang, Fu and Cui2019, Reference Jia, Xie, Yang, Fu and Cui2020). This Weber number is considered the effective aerodynamic force.

(2) According to (3.2), the relationship between the mean and oscillating velocity changed with the frequency, so this Weber number could unify the mean and oscillating velocity, making comparison possible among the results of different frequencies.

The experimental and theoretical values in figure 20 coincide well, but the error bands were larger than those in figure 18. This is because the envelopes of the surface wave were spatially oscillatory, rather than a simple exponential growth, which may have introduced larger error bars. Although this reason affected the exact value, the measured growth rates were also important indicators to evaluate the instability. The experimental results showed that the growth rate increased with increasing concentrations of the solutions. In fact, the increasing concentration led to an increase in liquid density and viscosity, suppressing the instability; meanwhile, the increasing concentration induced a decrease in surface tension, enhancing the instability. In addition, ![]() $W{e_l}$ was chosen as a constant, so the liquid velocity had to be reduced to guarantee the unchanged

$W{e_l}$ was chosen as a constant, so the liquid velocity had to be reduced to guarantee the unchanged ![]() $W{e_l}$. As a result, the gas-to-liquid velocity increased, enhancing the instability. When the destabilizing factors predominated over the stabilizing factors, the growth rate increased. However, theoretical results showed that the growth rate barely changed with the concentration of the solutions. This may be because the present theory overestimated the stabilizing effect of liquid viscosity and liquid density.

$W{e_l}$. As a result, the gas-to-liquid velocity increased, enhancing the instability. When the destabilizing factors predominated over the stabilizing factors, the growth rate increased. However, theoretical results showed that the growth rate barely changed with the concentration of the solutions. This may be because the present theory overestimated the stabilizing effect of liquid viscosity and liquid density.

Figure 21 displays the effect of ![]() $W{e_l}$. The liquid velocity was changed to change

$W{e_l}$. The liquid velocity was changed to change ![]() $W{e_l}$, but the liquid Reynolds number and the non-dimensional frequency also changed. Therefore, the Ohnesorge number and the non-dimensional frequency were defined as

$W{e_l}$, but the liquid Reynolds number and the non-dimensional frequency also changed. Therefore, the Ohnesorge number and the non-dimensional frequency were defined as ![]() $O{h_\textrm{l}} = {{\sqrt {W{e_l}} } / {R{e_l}}}$ and

$O{h_\textrm{l}} = {{\sqrt {W{e_l}} } / {R{e_l}}}$ and ![]() ${\varOmega _s} = {\omega _s}/\sqrt {\sigma /{\rho _\textrm{l}}{a^3}}$, respectively, which were independent of the liquid and gas velocities.

${\varOmega _s} = {\omega _s}/\sqrt {\sigma /{\rho _\textrm{l}}{a^3}}$, respectively, which were independent of the liquid and gas velocities.

Figure 21. Effect of liquid Weber number on instability: (a) ![]() $W{e_l} = 9.59$, (b)

$W{e_l} = 9.59$, (b) ![]() $W{e_l} = 10.63$, (c)

$W{e_l} = 10.63$, (c) ![]() $W{e_l} = 12.64$, (d)

$W{e_l} = 12.64$, (d) ![]() $W{e_l} = 14.98$ and (e)

$W{e_l} = 14.98$ and (e) ![]() $W{e_l} = 17.29$. (Full lines are theoretical curves; error bars are measured results; liquid is deionized water; air is gas;

$W{e_l} = 17.29$. (Full lines are theoretical curves; error bars are measured results; liquid is deionized water; air is gas; ![]() ${\rho _g} = 1.2\ \textrm{kg}\ {\textrm{m}^{ - 3}}$,

${\rho _g} = 1.2\ \textrm{kg}\ {\textrm{m}^{ - 3}}$, ![]() $a = 0.0002\ \textrm{m}$,

$a = 0.0002\ \textrm{m}$, ![]() ${f_s} = 142\ \textrm{Hz}$,

${f_s} = 142\ \textrm{Hz}$, ![]() $O{h_l} = 0.00819$,

$O{h_l} = 0.00819$, ![]() $\rho = 0.0012$,

$\rho = 0.0012$, ![]() ${\varOmega _s} = 0.3037$.)

${\varOmega _s} = 0.3037$.)

When the gas Weber number was relatively large, the growth rate decreased with increasing liquid Weber number. Theoretically, increasing the liquid Weber number should increase the liquid velocity (i.e. decreasing the gas-to-liquid velocity) and thus inhibit instability. According to Gaster (Reference Gaster1962), for a given temporal growth rate, the increase in group velocity leads to a decrease in the spatial growth rate, and the group velocity is almost directly proportional to the liquid velocity, i.e.

Therefore, the spatial growth rate decreased with increasing ![]() $W{e_l}$. From another perspective, the increase in

$W{e_l}$. From another perspective, the increase in ![]() $W{e_l}$ indicated an increase in the liquid inertia force, which represents the ability of the liquid sheet to maintain its initial state. The higher inertia force made it more difficult to destabilize the liquid sheet. However, when

$W{e_l}$ indicated an increase in the liquid inertia force, which represents the ability of the liquid sheet to maintain its initial state. The higher inertia force made it more difficult to destabilize the liquid sheet. However, when ![]() $W{e_{g2}}$ was relatively small, the results were the opposite. A surface wave with a shorter wavelength is more difficult to motivate, and

$W{e_{g2}}$ was relatively small, the results were the opposite. A surface wave with a shorter wavelength is more difficult to motivate, and

Obviously, the increase in liquid velocity led to an increase in the surface wavelength because the disturbance frequency was constant (equal to the oscillation frequency). Hence, the increase in ![]() $W{e_l}$ led to an increased growth rate at small

$W{e_l}$ led to an increased growth rate at small ![]() $W{e_{g2}}$.

$W{e_{g2}}$.

Moreover, when ![]() $W{e_{g2}}$ was relatively small, the measured growth rate was larger than the theoretical growth rate because the theoretical growth rate is a temporally mean growth rate in several periods. In fact, the liquid sheet was motivated by the gas pulse, inducing instantaneous growth, which was larger than the theoretically predicted mean growth rate. However, the experimental and theoretical results coincided well. Basically, the growth rate decreased with increasing

$W{e_{g2}}$ was relatively small, the measured growth rate was larger than the theoretical growth rate because the theoretical growth rate is a temporally mean growth rate in several periods. In fact, the liquid sheet was motivated by the gas pulse, inducing instantaneous growth, which was larger than the theoretically predicted mean growth rate. However, the experimental and theoretical results coincided well. Basically, the growth rate decreased with increasing ![]() $W{e_l}$ in the range studied.

$W{e_l}$ in the range studied.

The oscillating frequency of the gas velocity is also an important factor, as shown in figure 22. The liquid velocity was fixed in each panel to maintain ![]() $W{e_l}$. The amplitude–frequency characteristic and the power of the loudspeaker were limited, and the form of the surface wave at a particular frequency was affected by the liquid velocity. The growth rates at oscillation frequencies of 100 and 121 Hz are shown in figure 22(a,c) and the growth rates at oscillation frequencies of 142, 161 and 177 Hz are shown in figure 22(b,d). Because the disturbance frequency and the liquid velocity significantly influenced the instability, the non-dimensional frequency

$W{e_l}$. The amplitude–frequency characteristic and the power of the loudspeaker were limited, and the form of the surface wave at a particular frequency was affected by the liquid velocity. The growth rates at oscillation frequencies of 100 and 121 Hz are shown in figure 22(a,c) and the growth rates at oscillation frequencies of 142, 161 and 177 Hz are shown in figure 22(b,d). Because the disturbance frequency and the liquid velocity significantly influenced the instability, the non-dimensional frequency ![]() ${\varOmega _{s2}} = {\omega _s}a/{U_l}$, used in figure 16, is also used here. When

${\varOmega _{s2}} = {\omega _s}a/{U_l}$, used in figure 16, is also used here. When ![]() $W{e_{g2}}$ was relatively small (i.e. the aerodynamic force was relatively low), the low-frequency oscillation could induce larger wavelengths, and instability was more likely to be motivated; therefore, the growth rate of the low-frequency condition was higher than that of the high-frequency condition. However, with an increase in the aerodynamic force, the surface wave could also be motivated under high-frequency conditions. The growth rate increased quickly with increasing

$W{e_{g2}}$ was relatively small (i.e. the aerodynamic force was relatively low), the low-frequency oscillation could induce larger wavelengths, and instability was more likely to be motivated; therefore, the growth rate of the low-frequency condition was higher than that of the high-frequency condition. However, with an increase in the aerodynamic force, the surface wave could also be motivated under high-frequency conditions. The growth rate increased quickly with increasing ![]() $W{e_{g2}}$, even tending to exceed the low-frequency condition. This was determined by the dispersion relation of the instability. When

$W{e_{g2}}$, even tending to exceed the low-frequency condition. This was determined by the dispersion relation of the instability. When ![]() $W{e_{\textrm{g}2}}$ was larger, the high-frequency surface wave could be closer to the dominant frequency (the frequency corresponding to the maximum growth rate), so the growth rate could be faster.

$W{e_{\textrm{g}2}}$ was larger, the high-frequency surface wave could be closer to the dominant frequency (the frequency corresponding to the maximum growth rate), so the growth rate could be faster.

Figure 22. Effects of oscillation frequency on growth rate: (a,c) ![]() ${U_l} = 1.56\ \textrm{m}\ {\textrm{s}^{ - 1}}$,

${U_l} = 1.56\ \textrm{m}\ {\textrm{s}^{ - 1}}$, ![]() $W{e_l} = 7.01$; (b,d)

$W{e_l} = 7.01$; (b,d) ![]() ${U_l} = 2.07\ \textrm{m}\ {\textrm{s}^{ - 1}}$,