Article contents

Rate of SiC Deposition from Methyltrichlorosilane and Influence of HCL Addition

Published online by Cambridge University Press: 15 February 2011

Abstract

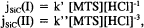

Suitable feedgas compositions for monophase SiC deposition were determined starting from methyltrichlorosilane-hydrogen-argon mixtures at 1 bar total pressure and H2/MTS ratios between 50 and zero. At temperatures from 900 to 1400°C, only a ratio of 1 at PMTS = 18 mbar gave the desired result. The deposition rate of SiC was determined as a function of MTS and HCl partial pressures, of gas flow rate, and of temperature at a H2/MTS ratio of 1. Two different rate equations were found at [MTS]/[HCI] ≥ 5.8 (region I) and < 5.8 (region II), respectively:

where brackets denote gas concentrations. The apparent activation energy was 380 kJ/mol common to both rate equations. A mathematical model taking into account temperature fields at reactor wall and substrate, heat and mass transport in the flowing gas, and heterogeneous reaction rates jSiC(I) and (II) was developed and found to be in very good agreement with the experimental results.

- Type

- Research Article

- Information

- Copyright

- Copyright © Materials Research Society 1995

References

- 1

- Cited by