Published online by Cambridge University Press: 13 September 2016

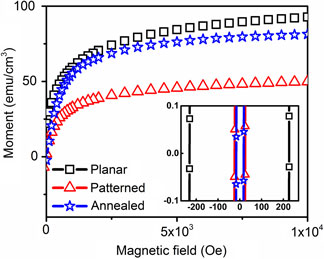

Surface patterned NiFe2O4 thin films exhibited large reduction in coercivity as compared with the films without surface patterning. Chemical analysis of the films revealed that there was no diffusion between the film and the substrate. Additional heating was shown to improve saturation magnetization without adverse effect on coercivity. The process of imprinting was eliminated as the possible cause of the phenomena as the flat stamp did not alter the magnetic properties of the film. Finally, it was shown that the orientation of the features with respect to the magnetic field does not have a significant effect on the magnetic response.