Article contents

Thermoelectric and mechanical properties of Ag and Cu doped (GeTe)0.96(Bi2Te3)0.04

Published online by Cambridge University Press: 08 August 2018

Abstract

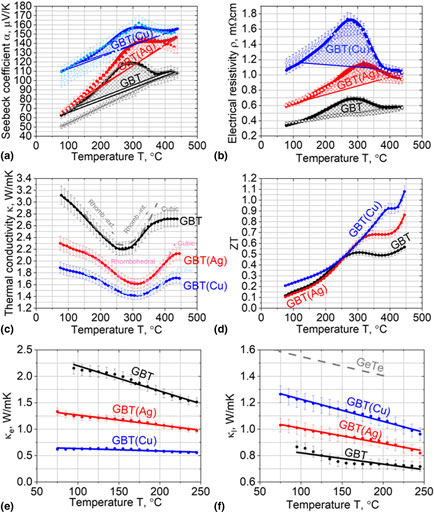

Thermoelectric (TE) is a heat-to-electricity energy conversion method with increasing attention. In recent years, novel highly efficient TE materials, including GeTe and other IV–VI based alloys, were reported, mainly due to either electronic optimization of transport properties or nanostructuring for minimization of the lattice thermal conductivity. Yet, the mechanical properties of such materials (with brittle nature), which are significant for obtaining the required durability under the associated thermo-mechanical conditions of practical applications, were much less tackled. The challenge is combining the both, upon introducing alloying elements, positively contributing both the TE figure of merit and the mechanical durability. In the current research, the TE and mechanical (mainly compression and fracture toughness) effects of Ag- and Cu-doping of the GeTe-rich (GeTe)0.96(Bi2Te3)0.04 alloy were investigated, suggesting improvement on both aspects.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

These authors equally contributed to the research.

References

- 8

- Cited by