Article contents

Enhanced mechanical properties of machinable mica glass ceramics at cryogenic temperatures

Published online by Cambridge University Press: 01 December 2016

Abstract

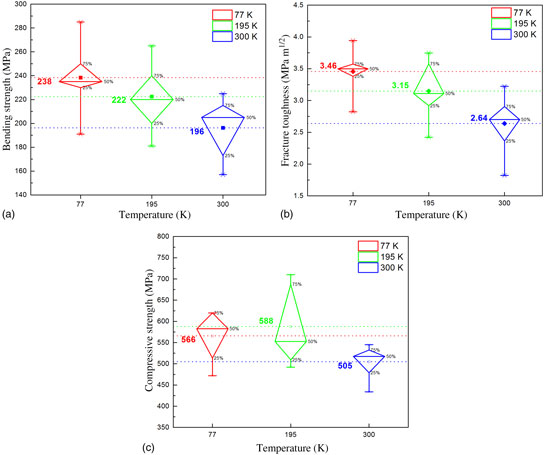

Machinable mica glass ceramics were synthesized by sintering method. The crystal phase was characterized using x-ray diffraction, showing that the main crystal phase was fluorophlogopite. Mechanical properties were measured at different temperatures. The results demonstrated that bending strength and fracture toughness increased 28% and 24% when temperature decreased from 300 to 77 K, respectively. Compressive strength also increased at cryogenic temperatures, but a higher value was obtained at 195 K. According to scanning electron microscope observation, the extraction of mica platelets was observed at 77 K, which may be the toughening mechanism of machinable mica glass ceramics.

- Type

- Research Letters

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

- 3

- Cited by