No CrossRef data available.

Article contents

Vacuum brazing of TC4 alloy to AlMgB14–TiB2 ceramic using AgCu filler

Published online by Cambridge University Press: 07 May 2019

Abstract

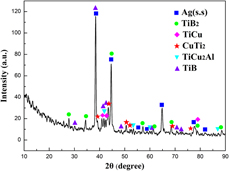

AlMgB14–TiB2 ceramic was successfully brazed to TC4 alloy with inactive AgCu filler alloy. X-ray diffractometer, SEM, and energy-dispersive spectrometer were used to study interfacial microstructure and shear strength of the joints under different brazing temperatures. The results indicated that the typical microstructure of the TC4/AlMgB14–TiB2 joint was TC4/Ti(s.s) + Ti2Cu/Ti2Cu/TiCu/TiCu2Al/Ag(s.s) + Cu(s.s)/TiB whiskers/TiB2 reaction layer/AMBT. By increasing the brazing temperature, the thickness of the TC4 diffusion layer was improved, whereas that of the brazing seam decreased remarkably. When the brazing temperature was increased to 880 °C, the brazing seam was composed of Ti–Cu intermetallic Ag(s.s) with a few Cu(s.s), TiCu2Al distributed. Meanwhile, the formation of a continuous TiB2 reaction layer at the interface of the AMBT and brazing filler facilitated the improvement of joint shear strength. The joint with the maximum shear strength of 46.7 MPa was obtained while brazing at 880 °C for 10 min.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019