Article contents

Thermal stability of a nanostructured layer on the surface of 316L stainless steel

Published online by Cambridge University Press: 17 February 2014

Abstract

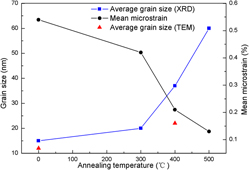

To obtain a nanocrystalline surface layer, 316L stainless steel was treated by fast multiple rotation rolling (FMRR). The microstructure, after FMRR treatment and annealing treatment, was characterized by transmission electron microscopy and x-ray diffraction. Equiaxed nanocrystalline with the average grain size about 12 nm is obtained on the surface layer of FMRR sample. The investigation of thermal stability of the nanocrystalline layer indicates that the grains are still nanocrystalline and the average grain size is about 60 nm for annealing at 500 °C. In addition, the amount of α-martensite increases markedly as the annealing temperature increases from 300 to 500 °C. However, it begins to reduce at 600 °C due to the reversion transformation from martensite to austenite. After annealing at 400 °C, the microhardness of the annealed FMRR sample reaches a maximum value of about 660 HV, and it is four times higher than that of the original sample.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2014

References

REFERENCES

- 4

- Cited by