Article contents

Synthesis of highly porous alumina-based oxides with tailored catalytic properties in the esterification of glycerol

Published online by Cambridge University Press: 22 October 2018

Abstract

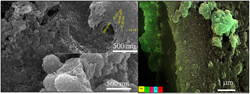

Highly porous alumina-based oxides, γ-Al2O3, SiO2–Al2O3, and TiO2–Al2O3 were synthesized by a modified sol–gel method. Polivinylpyrrolidone was used as the pore expanding agent, whereas cetyltrimethylammonium bromide was used as the template in the presence of alkoxide inorganic precursors. Both as-synthesized and calcined solids were used as catalysts for esterification of glycerol with acetic acid (EG). The XRD and SEM-EDS measurements demonstrated that the Si-containing solids are amorphous while those containing Ti are semicrystalline with the latter composed of TiO2 rutile, TiO2 anatase, and γ-Al2O3 phases. All solids possessed ordered porous structures comprising of micro- and mesoporosity, with interconnectivity between these pores of different length scales. The high acidity of γ-Al2O3 and TiO2–Al2O3 materials resulted in good catalytic performances in the EG. Porosity of the solids plays a secondary role in determining the catalytic activity. Under the same conditions, the as-synthesized solids exhibited slightly lower catalytic performances compared to that of the calcined ones.

- Type

- Article

- Information

- Journal of Materials Research , Volume 33 , Issue 21: Focus Issue: Catalytic Engineered Materials for Commercial and Industrial Energy Applications , 14 November 2018 , pp. 3625 - 3633

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 6

- Cited by