Article contents

Study on the precipitates in various aging stages and composite strengthening effect of precipitates and long-period stacking ordered structure of Mg–Gd–Y–Ni alloy

Published online by Cambridge University Press: 13 January 2020

Abstract

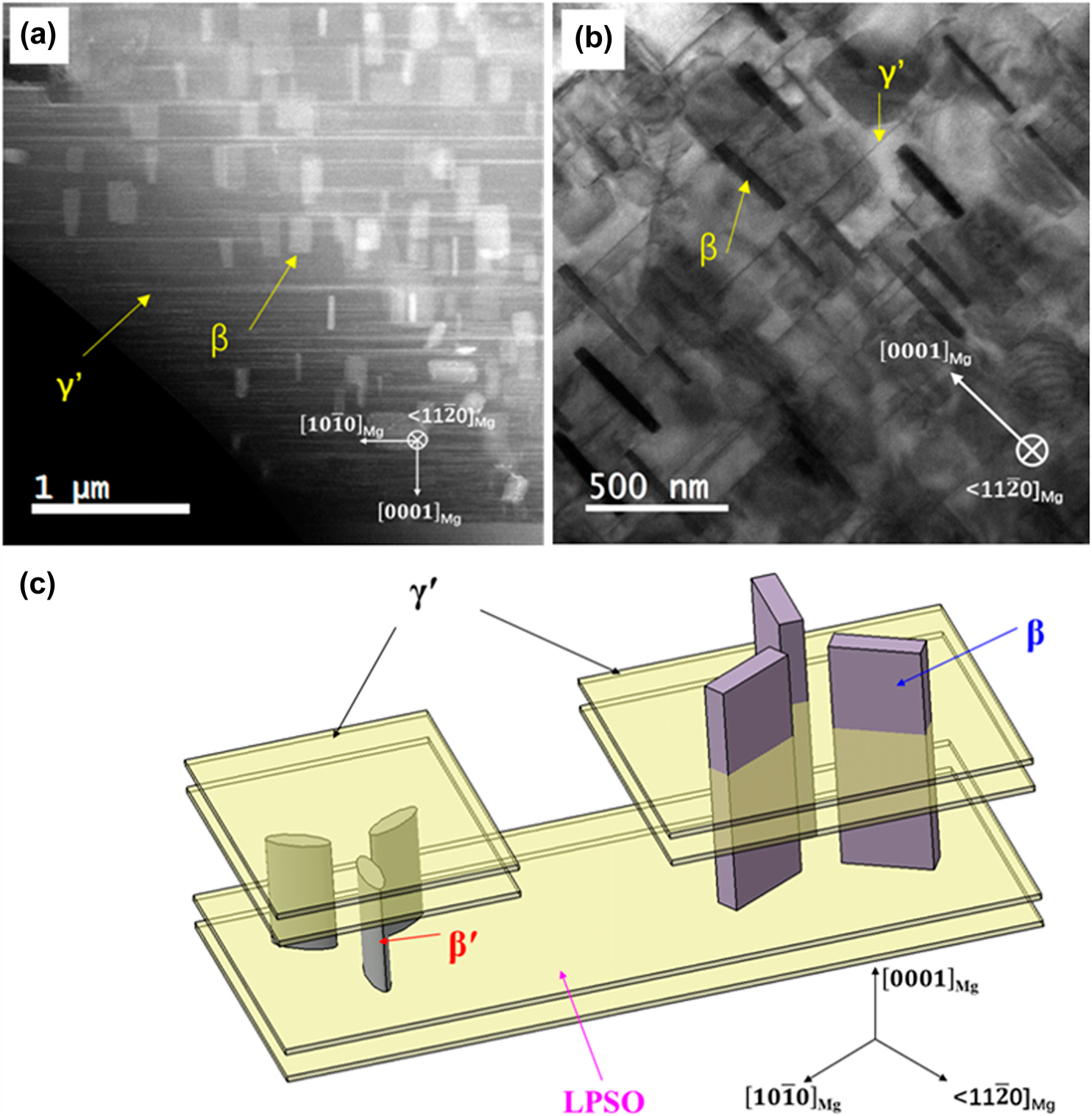

In this paper, the atomic resolution high-angle annular dark-field scanning transmission electron microscope (HAADF-STEM) was used as the main research method. Using HAADF-STEM, two types of long-period stacking ordered structure (LPSO)—14H and 18R-LPSO—were observed in Mg96Gd2Y1Ni1 alloy, and the precipitates at various stages of aging were observed. Moreover, a type of rectangular β precipitates were found, and the atomic models of β precipitates along the [0001]Mg and  ${\tf="TeXGyrePagella-Bold (TrueType)"\char9001} 11\bar 20\hbox{]}_{{\rm{Mg}}}$ directions were identified. At the aging peak stage, a three-dimensional network structure composed of LPSO/γ′ precipitates and β′ precipitates and β precipitates was observed. The hardness of the unaged homogenized Mg96Gd2Y1Ni1 alloy was only 87 HV and the hardness value of aging peak was 128.4 HV. Compared with the unaged alloy, the hardness of the peak-aged alloy increased by 47.59%. The composite strengthening of the three types of precipitates induced a significant strengthening to the alloy.

${\tf="TeXGyrePagella-Bold (TrueType)"\char9001} 11\bar 20\hbox{]}_{{\rm{Mg}}}$ directions were identified. At the aging peak stage, a three-dimensional network structure composed of LPSO/γ′ precipitates and β′ precipitates and β precipitates was observed. The hardness of the unaged homogenized Mg96Gd2Y1Ni1 alloy was only 87 HV and the hardness value of aging peak was 128.4 HV. Compared with the unaged alloy, the hardness of the peak-aged alloy increased by 47.59%. The composite strengthening of the three types of precipitates induced a significant strengthening to the alloy.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 4

- Cited by