Article contents

Study of the synthetic process of CaBi2Ta2O9 powder by the molten-salt method

Published online by Cambridge University Press: 29 October 2020

Abstract

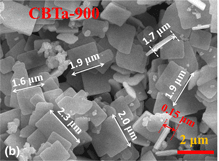

The molten-salt method was used to synthesize CaBi2Ta2O9 (CBTa) powder, and the influence of temperature on the structure and micromorphology of products was investigated using X-ray diffraction and the scanning and transmission electron microscope. The results showed that highly crystalline CBTa nanoplates exhibit single orthorhombic symmetry and could be obtained in the temperature range of 850–900 °C. Among which, the nanoplates prepared at 900 °C have optimal properties (average grain size of 1.7 μm and uniform size distribution). Above 900 °C, various CaO–Ta2O5 binary compounds, Bi2O3, and BiTaO4 formed due to the decomposition of CBTa and subsequent reactions of decomposition products, transforming plate-like grains to cuboid nano-particles with a small amount of prismatic grains. Possible reaction mechanisms at different synthesizing temperature were proposed. This work provides a method for the preparation of template grains to synthesize textured CaBi2Ta2O9 high-temperature piezoelectric ceramics by the template grain growth method.

- Type

- Invited Feature Paper

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 2

- Cited by