Article contents

Structural and crystallographic study on 3004 aluminum alloy ingot by horizontal direct chill casting under combined electromagnetic fields

Published online by Cambridge University Press: 20 February 2015

Abstract

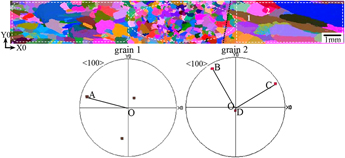

Effect of combined electromagnetic fields (EMFs) on the structures of a 3004 aluminum alloy ingot produced by horizontal direct chill casting was crystallographically investigated. The results showed that the structure was transformed from a mixture of equiaxed and fine columnar grains to coarse columnar grains with switching off the EMFs. With the EMFs the grain size is small and shows a uniform distribution, whereas without the EMFs it is increased and reveals inhomogeneous distribution on the cross section. Besides, a transition region composed of fine equiaxed grains appeared at the moment the EMFs were switched off (between the mixture and coarse columnar grains). Furthermore, the microstructure transformation is accompanied by a crystallographic orientation change from a preferred <100> orientation to a random orientation, and then to an intense <100> fiber texture. The structural and crystallographic transformations are mainly related to the forced convection in the melt due to the induced Lorentz force by the EMFs.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 8

- Cited by