Article contents

Rotation field in wedge indentation of metals

Published online by Cambridge University Press: 23 September 2011

Abstract

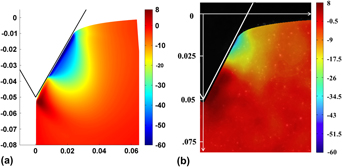

A study is made of the rotation field in wedge indentation of metals using copper as the model material system. Wedges with apical angles of 60° and 120° are used to indent annealed copper, and the deformation is mapped using image correlation. The indentation of annealed and strain-hardened copper is simulated using finite element analysis. The rotation field, derived from the deformation measurements, provides a clear way of distinguishing between cutting and compressive modes of deformation. Largely unidirectional rotation on one side of the symmetry line with small spatial rotation gradients is characteristic of compression. Bidirectional rotation with neighboring regions of opposing rotations and locally high rotation gradients characterizes cutting. In addition, the rotation demarcates such characteristic regions as the pile-up zone in indentation of a strain-hardened metal. The residual rotation field obtained after unloading is essentially the same as that at full load, indicating that it is a scalar proxy for plastic deformation as a whole.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 1: Focus Issue: Instrumented Indentation , 14 January 2012 , pp. 284 - 293

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 4

- Cited by