Article contents

Role of stress in the high cycle fatigue behavior of advanced 9Cr/CrMoV dissimilarly welded joint

Published online by Cambridge University Press: 11 January 2016

Abstract

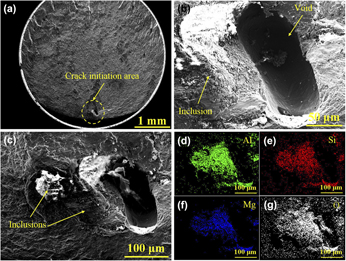

Narrow gap submerged arc welding method accompanied with multilayer and multipass technology was used to manufacture advanced 9Cr and CrMoV dissimilarly welded joint used as a newly developed turbine rotor. The aim of this investigation was to evaluate the high cycle fatigue (HCF) behavior of the welded joint at room temperature. Uniaxial-stress controlled HCF tests at stress ratio R = −1 were performed with specimens chipped from the welded joint of mockup and the S–N curve up to 1.0 × 108 cycle lifetime was obtained. It was found that the fracture location transferred from heat affected zone (HAZ) of CrMoV side to weld metal (WM) with decreasing stress amplitude. The microstructure of the welded joint was characterized and microstructure diversity was found to be responsible for the failure locations both in the CrMoV–HAZ and WM. Fracture morphology of failure samples were also investigated by a scanning electron microscope. It is detected that the stress amplitude required to drive the inclusion to be the crack initiation of the CrMoV–HAZ lies behind the transition. With decreasing stress amplitudes, void in the WM more easily tends to be the initiation of a fatigue crack than inclusion.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 11

- Cited by