Article contents

Processing and electrochemical properties of CNT reinforced carbon nanofibers prepared by pressurized gyration

Published online by Cambridge University Press: 12 November 2018

Abstract

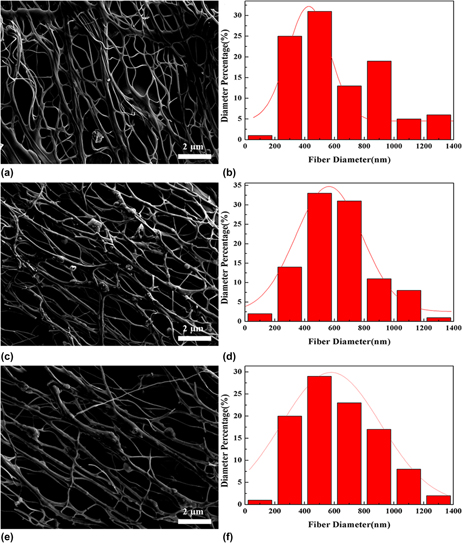

Carbon nanotubes (CNTs) were added to carbon nanofibers (CNFs) as additives to improve their electrochemical properties. In the present work, CNFs were prepared by using pressurized gyration with polyacrylonitrile as the precursor. The microstructure and electrochemical properties of samples were investigated by scanning electron microscopy and electrochemical workstation, respectively. The results showed that the network structure formed in the fiber, and the fiber diameter decreased with the increase of working pressure. The integral area of cyclic voltammetry curve reached the maximum and the charge/discharge time of constant current charge/discharge curve reached the longest in the case of the CNT concentration is 0.50 wt% and working pressure is 0.2 MPa. At the same time, it exhibited the best electrochemical performance with a specific capacitance of 79 F/g at a current density of 100 mA/g. Compared with the specific capacitance of pure CNFs, the specific capacitance of CNFs with the concentration of CNTs 0.50 wt% increased by about 40%.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 2

- Cited by