Published online by Cambridge University Press: 24 June 2020

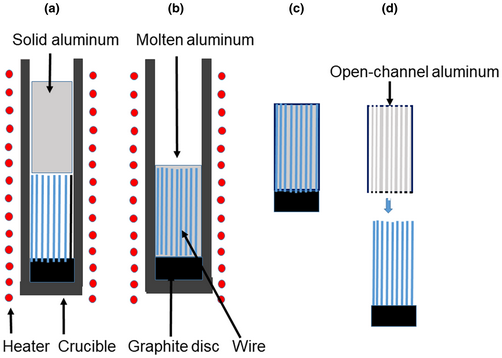

This paper reviews the recent development of fabrication methods of porous metals with open-channels. The open-channel metals are fabricated through powder sintering or solidification technique. The template wires are embedded in the sintered or solidified metals, such as aluminum, copper, titanium and its alloys, which are then removed by chemical dissolution or extraction methods. The hole size, hole length and porosity are uniquely controlled by thickness, length and number of template metallic wires, respectively. The pore size ranges from 102 to several 103 μm in diameter. The open-channel metals are characterized by a large aspect ratio of the length to the diameter of the holes in metals. Furthermore, the techniques can fabricate spiral and V-shaped pores in metals. Feasibility and usefulness of each fabrication method are discussed. The methodology for producing the open-channel metals is expected to provide expanded opportunities for application technologies such as functional materials like heat sinks and sound absorbers and light-weight structural materials.