Article contents

Microstructures and mechanical properties of bulk nanocrystalline silver fabricated by spark plasma sintering

Published online by Cambridge University Press: 10 June 2016

Abstract

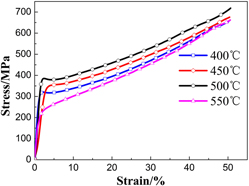

Bulk nanocrystalline (NC) silvers were fabricated by spark plasma sintering process. The effects of sintering temperature on physical and mechanical properties of the NC silvers were investigated. The results indicate that no impurities were introduced into the bulk compacts during the preparation procedure. Both the density and the electrical conductivity of the NC Ag increase with an increase in sintering temperature. However, the micro-hardness and ultimate tensile strength (UTS) of the bulk compacts increase initially and then decrease with increasing sintering temperature. The NC Ag sintered at 500 °C exhibits the highest micro-hardness of 85.3 HV along with the best compression yield strength of 379 MPa and the highest UTS of 534 MPa. The deterioration of the mechanical properties of the NC Ag sintered at 550 °C should be attributed to the rapid grain growth.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 3

- Cited by