Article contents

The microstructure evolution and element segregation of Inconel 617 alloy tungsten inert gas welded joint

Published online by Cambridge University Press: 03 February 2016

Abstract

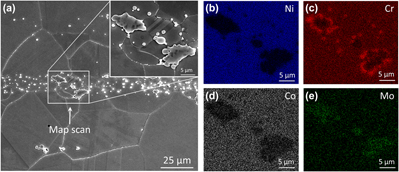

Inconel 617 alloy (IN 617) is an important candidate material of advanced ultrasupercritical power unit above 700 °C. However, there are some issues in welding of IN 617 such as constitutional liquation and hot cracking. Tungsten inert gas (TIG) is considered as an effective welding method to join IN 617 because of low heat input and high quality. Investigation of the microstructure variation of TIG welded joint and its correlation with properties is helpful in deep understanding the stability and reliability of IN 617 welded joint. In this paper, the microstructure evolution and element segregation of IN 617 welded joint were investigated systematically. It is found that the base metal (BM) with significant banded structure is characterized by austenitic grains and some secondary phases distribute along the grain boundaries and inside the grains. The fine secondary phases are determined as M23C6 enriched with Cr and Mo elements. A few large polygon phases are identified as Ti(C, N) with a size of about 10 μm. The coarsened secondary phases are observed in the heat affected zone (HAZ) close to BM whilst the lamellar structure enriched with Cr and Mo is present along grain boundaries in the HAZ near the fusion line. The weld metal (WM) is fully austenitic with a dendritic structure and contains particles dispersing in the matrix. The element segregation on grain boundaries of IN 617 welded joint was analyzed by energy dispersive spectrometer. No obvious element segregation was observed in HAZ. In WM, the area in the vicinity of solidification grain boundaries and solidification subgrain boundaries (SSGBs) has a local depletion of Ni and Co while the Cr and Mo have no obvious segregation. Microhardness and high temperature tensile test of BM and WM were conducted. The WM has a little bit larger hardness value than BM and HAZ because of the strengthening effect of SSGBs. The fracture position is determined in the middle of WM, which is attributed to the grain boundary failure in the center of WM. The high temperature tensile properties of the welded joint are close to BM. In this investigation, the constitutional liquation in HAZ and solidification in WM have little effect on the high temperature tensile properties. TIG welding method is proved to be a suitable welding method to join IN 617.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 18

- Cited by