Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wang, N.

Wang, D.P.

Yang, Z.W.

and

Wang, Y.

2016.

Interfacial microstructure and mechanical properties of zirconia ceramic and niobium joints vacuum brazed with two Ag-based active filler metals.

Ceramics International,

Vol. 42,

Issue. 11,

p.

12815.

Wang, N.

Wang, D.P.

Yang, Z.W.

Wang, Y.

and

Liu, X.G.

2017.

Zirconia ceramic and Nb joints brazed with Mo-particle-reinforced Ag-Cu-Ti composite fillers: Interfacial microstructure and formation mechanism.

Ceramics International,

Vol. 43,

Issue. 13,

p.

9636.

Yang, Z.W.

Wang, C.L.

Wang, Y.

Zhang, L.X.

Wang, D.P.

and

Feng, J.C.

2017.

Active metal brazing of SiO 2 –BN ceramic and Ti plate with Ag–Cu–Ti + BN composite filler.

Journal of Materials Science & Technology,

Vol. 33,

Issue. 11,

p.

1392.

Zhang, Qi

Wang, Juan

Zheng, Kaihong

Lu, Yao

and

Yang, Hongwang

2019.

Microstructure evolution and mechanical properties of ZrO2/ZrO2 joints brazed with Ni–Ti filler metal.

Materials Research Express,

Vol. 6,

Issue. 12,

p.

126547.

Chou, Tsung‐Te

Tuan, Wei‐Hsing

and

Lin, Kun‐Lin

2019.

Interface evaluation on the brazed system of AlN‐Ticusil‐Graphite.

International Journal of Applied Ceramic Technology,

Vol. 16,

Issue. 6,

p.

2236.

Avettand-Fènoël, M.-N.

Naji, K.

and

Pouligny, Ph.

2019.

Brazing vs. diffusion welding of graded Fe based matrix composite and yttria stabilized zirconia.

Journal of Manufacturing Processes,

Vol. 45,

Issue. ,

p.

557.

Ong, Fei Shen

Tobe, Hirobumi

and

Sato, Eiichi

2019.

Intermetallics evolution and fracture behavior of Nb interlayer inserted Si3N4/Ti joints brazed with AgCuTi filler.

Materials Science and Engineering: A,

Vol. 762,

Issue. ,

p.

138096.

Li, Lin

Wei, Can

and

Shen, Ping

2020.

Electrochemically driven rapid wetting of 3YSZ by 60Cu–40Ag and its robust joining to 304 stainless steel.

Journal of the European Ceramic Society,

Vol. 40,

Issue. 12,

p.

4281.

Jin, Chenkai

Wang, Ying

Yang, Zhenwen

and

Wang, Dongpo

2020.

C/C composite surface modified by electrophoretic depositing SiC nanowires and its brazing to Nb.

Ceramics International,

Vol. 46,

Issue. 1,

p.

204.

Guo, Weibing

Xue, Haitao

Wei, Xin

and

Zhang, Xiaoming

2020.

Study on the interfacial properties of active Ti element/ZrO2 by using first principle calculation.

International Journal of Applied Ceramic Technology,

Vol. 17,

Issue. 3,

p.

1286.

Fan, Zhou

Wang, Yang

Zhang, Yidong

Yan, Jiazhen

Liu, Jianyi

Tang, Peng

and

Zhang, Qinghui

2021.

First-Principles Investigation on Wetting Interface of Yttrium Stabilized Tetragonal Zirconia Ceramic Filled with AgCuTi Active Filler.

SSRN Electronic Journal ,

Yao, Yujie

Han, Yong

Zhang, Kaiyu

Zhu, Haohao

Zhang, Wanliang

Qian, Hangli

Zhou, Chengshuang

and

Zhang, Lin

2022.

The dependence of fracture mode on interfacial microstructure in TA1 pure titanium/AgCuNi/304 stainless steel vacuum brazed joints.

Vacuum,

Vol. 203,

Issue. ,

p.

111318.

Qi, Fugong

Wang, Na

Yang, Zhenwen

Wang, Ying

and

Li, Huijun

2022.

Blackening Mechanism and Mechanical Properties Variation of Zirconia Ceramic Induced by Active Metal Brazing.

Advanced Engineering Materials,

Vol. 24,

Issue. 9,

LIU, Duo

CHEN, Bin

JIN, Guobiao

SONG, Yanyu

ZHANG, Qi

SONG, Xiaoguo

and

CAO, Jian

2022.

Interfacial characteristics in CNTs-AgCuTi systems.

Chinese Journal of Aeronautics,

Vol. 35,

Issue. 4,

p.

450.

Gambaro, S.

Valenza, F.

Muolo, M.L.

Passerone, A.

Riani, P.

and

Cacciamani, G.

2022.

Zirconia-high entropy alloys joints for biomedical applications: The role of Ag-based fillers on interfacial reactivity.

Journal of Alloys and Compounds,

Vol. 909,

Issue. ,

p.

164764.

Zhou, Wenlong

Liu, Di

Fu, Wei

Wang, Huaijin

Song, Xiaogong

Hu, Shengpeng

and

Niu, Hongwei

2022.

Insight into the wetting behavior of AgCu‐xTi on ZrO2: Spreading and microstructural evolution.

Journal of the American Ceramic Society,

Vol. 105,

Issue. 10,

p.

6076.

YAO, Yujie

Han, Yong

ZHANG, Lin

Zhang, Kaiyu

Zhu, Haohao

Zhang, Wanliang

Qian, Hangli

and

Zhou, Chengshuang

2022.

The Dependence of Fracture Mode On Interfacial Microstructure in Ta1 Pure Titanium/Agcuni/304 Stainless Steel Vacuum Brazed Joints.

SSRN Electronic Journal ,

Yang, Z.W.

Xiong, Z.

Wang, J.L.

Wang, Y.

and

Wang, D.P.

2023.

Microstructural evolution and high-temperature oxidation resistance of YSZ/Crofer 22H brazed joints using Ag-based filler for solid-oxide fuel cell applications.

Materials Characterization,

Vol. 200,

Issue. ,

p.

112888.

Habibi, Farzad

and

Samadi, Ahad

2023.

Interfacial reactions in actively brazed Cu-Al2O3 composites and copper using a newly developed Cu-Sn-Ag-Ti filler alloy.

Science and Technology of Welding and Joining,

Vol. 28,

Issue. 6,

p.

444.

Fang, Miaomiao

Liu, Ben

Wang, Yong

Yang, Zhenwen

and

Wang, Ying

2023.

Interfacial microstructure and mechanical properties of joints between ZrO2 ceramic and 316 stainless steel brazed using Ag–Cu–In–Ti filler.

Vacuum,

Vol. 218,

Issue. ,

p.

112668.

$\left[ {111} \right]_{{\rm{Cu}}_{\rm{2}} {\rm{O}}} //\left[ {111} \right]_{{\rm{Ag}}}$ and

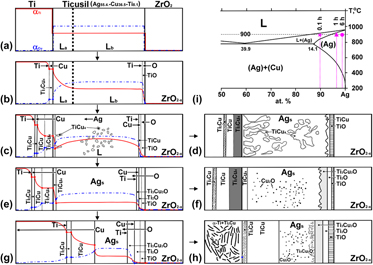

$\left[ {111} \right]_{{\rm{Cu}}_{\rm{2}} {\rm{O}}} //\left[ {111} \right]_{{\rm{Ag}}}$ and  $\left( {20\bar 2} \right)_{{\rm{Cu}}_{\rm{2}} {\rm{O}}} //\left( {20\bar 2} \right){}_{{\rm{Ag}}}$. After brazing at 900 °C/6 h, a two-phase (α-Ti + Ti2Cu) region was observed on the Ti side with

$\left( {20\bar 2} \right)_{{\rm{Cu}}_{\rm{2}} {\rm{O}}} //\left( {20\bar 2} \right){}_{{\rm{Ag}}}$. After brazing at 900 °C/6 h, a two-phase (α-Ti + Ti2Cu) region was observed on the Ti side with  $\left[ {2\bar 1\bar 10} \right]_{{\rm{\alpha - Ti}}} //\left[ {100} \right]_{{\rm{Ti}}_{\rm{2}} {\rm{Cu}}}$ and

$\left[ {2\bar 1\bar 10} \right]_{{\rm{\alpha - Ti}}} //\left[ {100} \right]_{{\rm{Ti}}_{\rm{2}} {\rm{Cu}}}$ and  $\left( {0002} \right)_{{\rm{\alpha - Ti}}} //\left( {0\bar 13} \right)_{{\rm{Ti}}_{\rm{2}} {\rm{Cu}}}$, while the TiCu layer grew at the expense of Ti3Cu4 and TiCu4. The bonding mechanisms and diffusion paths were explored with the aid of Ag–Cu–Ti and Ti–Cu–O ternary phase diagrams.

$\left( {0002} \right)_{{\rm{\alpha - Ti}}} //\left( {0\bar 13} \right)_{{\rm{Ti}}_{\rm{2}} {\rm{Cu}}}$, while the TiCu layer grew at the expense of Ti3Cu4 and TiCu4. The bonding mechanisms and diffusion paths were explored with the aid of Ag–Cu–Ti and Ti–Cu–O ternary phase diagrams.