Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Gigax, Jonathan G.

Torrez, Avery J.

McCulloch, Quinn

Kim, Hyosim

Maloy, Stuart A.

and

Li, Nan

2020.

Sizing up mechanical testing: Comparison of microscale and mesoscale mechanical testing techniques on a FeCrAl welded tube.

Journal of Materials Research,

Vol. 35,

Issue. 20,

p.

2817.

Pateras, Anastasios

Harder, Ross

Cha, Wonsuk

Gigax, Jonathan G.

Baldwin, J. Kevin

Tischler, Jon

Xu, Ruqing

Liu, Wenjun

Erdmann, Mark J.

Kalt, Robert

Sandberg, Richard L.

Fensin, Saryu

and

Pokharel, Reeju

2020.

Combining Laue diffraction with Bragg coherent diffraction imaging at 34-ID-C.

Journal of Synchrotron Radiation,

Vol. 27,

Issue. 5,

p.

1430.

Lieou, Charles K.C.

and

Bronkhorst, Curt A.

2020.

Thermodynamic theory of crystal plasticity: Formulation and application to polycrystal fcc copper.

Journal of the Mechanics and Physics of Solids,

Vol. 138,

Issue. ,

p.

103905.

Xu, Dongdong

Edwards, Thomas E.J.

Liao, Zhirong

Maeder, Xavier

Ramachandramoorthy, Rajaprakash

Jain, Manish

Michler, Johann

and

Axinte, Dragos

2021.

Revealing Nanoscale deformation mechanisms caused by shear-based material removal on individual grains of a Ni-based superalloy.

Acta Materialia,

Vol. 212,

Issue. ,

p.

116929.

Pelleg, Joshua

2021.

Mechanical Properties of Nanomaterials.

p.

83.

Li, Shuang

Powell, Cynthia A.

Mathaudhu, Suveen

Gwalani, Bharat

Devaraj, Arun

and

Wang, Chongmin

2022.

Review of recent progress on in situ TEM shear deformation: a retrospective and perspective view.

Journal of Materials Science,

Vol. 57,

Issue. 26,

p.

12177.

Gigax, Jonathan G.

Chancey, Matthew R.

Xie, Dongyue

Kim, Hyosim

Wang, Yongqiang

Maloy, Stuart A.

and

Li, Nan

2022.

A Novel Microshear Geometry for Exploring the Influence of Void Swelling on the Mechanical Properties Induced by MeV Heavy Ion Irradiation.

Materials,

Vol. 15,

Issue. 12,

p.

4253.

Fang, Fengzhou

Lai, Min

Wang, Jinshi

Luo, Xichun

Yan, Jiwang

and

Yan, Yongda

2022.

Nanometric cutting: Mechanisms, practices and future perspectives.

International Journal of Machine Tools and Manufacture,

Vol. 178,

Issue. ,

p.

103905.

Ajantiwalay, Tanvi

Ma, Xiaolong

Yu, Anqi

Pole, Mayur

Silverstein, Joshua

Mathaudhu, Suveen

Devaraj, Arun

and

Gwalani, Bharat

2023.

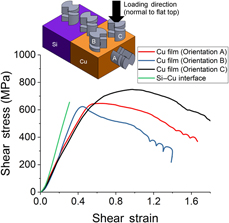

Shear deformation of pure-Cu and Cu/Nb nano-laminates using micromechanical testing.

Scripta Materialia,

Vol. 230,

Issue. ,

p.

115403.

Escobar, Julian

Silverstein, Joshua

Ishrak, Farhan

Li, Lei

Soulami, Ayoub

Li, Shuang

Yu, Anqi

Mathaudhu, Suveen

Ortiz, Angel

Koch, Carl

Devaraj, Arun

Efe, Mert

and

Gwalani, Bharat

2023.

Microstructural evolution in shear-punch tests: A comparative study of pure Cu and Cu-Cr alloy.

Materials Science and Engineering: A,

Vol. 886,

Issue. ,

p.

145715.

Han, Guofeng

He, Ji

Li, Shuhui

and

Lin, Zhongqin

2024.

Simple shear methodology for local structure–property relationships of sheet metals: State-of-the-art and open issues.

Progress in Materials Science,

Vol. 143,

Issue. ,

p.

101266.