Article contents

Investigation of microstructure and mechanical properties of the Cu–3% Ti alloy processed by multiaxial cryo-forging

Published online by Cambridge University Press: 07 August 2018

Abstract

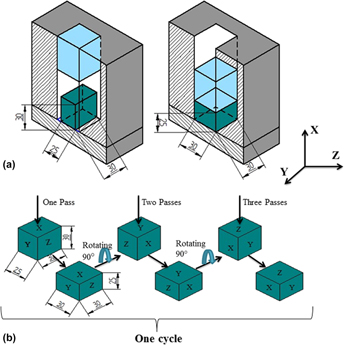

A Cu–3%Ti (wt%) alloy was processed by multiaxial forging (MAF) at cryogenic temperature up to 3 cycles, imposing a total strain of 1.6. Microstructure and mechanical properties of the unprocessed and cryo-forged samples were analyzed. X-ray diffraction results showed deviation in peak broadening and peak intensity of the cryo-forged samples in comparison to that of unprocessed, which are due to texture modification caused by grain refinement during the MAF process. Microstructural analysis showed reduction in grain size from 80 µm in the as-received condition to 250 nm after 3 cycles. Electron backscatter diffraction results indicated the transformation of high angle grain boundaries to low angle grain boundaries in all 3 cycles when compared to the as-received condition. Reduction in ductility was observed after 1 cycle, but with an increase in the number of cycles, both strength and ductility increased. After 3 cycles, ultimate tensile strength and hardness reached 1126 MPa and 427 Hv as compared to 528 MPa and 224 Hv for the as-received condition. Fractography analysis showed decrement in dimple size after 1 cycle, in comparison to that of the as-received condition. However, it kept on increasing for higher number of cycles.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 12

- Cited by