Article contents

Influence of the deformation heating on the flow behavior of 6063 alloy during compression at medium strain rates

Published online by Cambridge University Press: 05 November 2018

Abstract

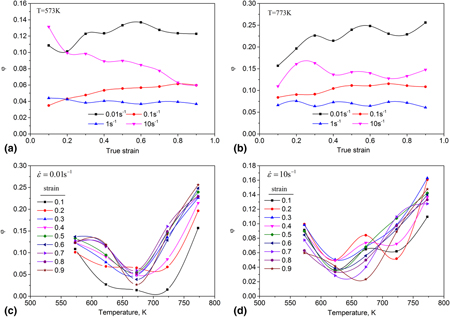

The flow softening behavior caused by deformation heating of the 6063 aluminum alloy was investigated employing uniaxial compression tests. The adiabatic correction factor (η) and mechanical work partitioning factor (φ), commonly considered to be constant, were found to be highly variable at medium strain rates, namely from 0.01 to 10 s−1. η decreased with increasing strain and decreasing strain rate, but it was relatively not sensitive to temperature. φ, traditionally taken to be a constant of 0–10%, was found to vary from 2.8% at a temperature of 623 K and a strain rate of 10 s−1 to 26.8% at a temperature of 773 K with a strain rate of 0.01 s−1. An expression for temperature rise involving these two variable factors was optimized. FEM simulation using the corrected and uncorrected true stress–strain curves and corresponding extrusion experiment were carried out. Comparisons between the simulated and experimental results confirmed the temperature compensation was trustable.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 5

- Cited by