Article contents

The influence of heat treatment on the structure and tensile properties of thin-section A356 aluminum alloy casts refined by Ti, B and Zr

Published online by Cambridge University Press: 29 May 2017

Abstract

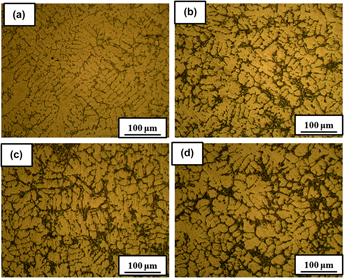

The aim of this study is to investigate the effects of different master alloys containing Ti, B, and Zr on the structure and tensile properties of thin-section A356 aluminum alloy in as-cast and T6-treated conditions. Microstructural examinations were performed using light optical and scanning electron microscopy. The results showed that the addition of 0.1 wt% Ti, 0.05 wt% B, and 0.1 wt% Zr decreases the average grain size of the cast alloy from 840 μm to 387 μm, 236 μm, and 363 μm, respectively. This structural refinement results in the variation of the α-Al primary phase distribution mode from dendritic to rosettelike. It has been found that 0.6 wt% Al–8B master alloy (0.05 wt% B) is the strongest to refine the structural parameters. This leads to the enhancement of both ultimate tensile strength and elongation values from 208 MPa and 6.2% in as-cast to 290 MPa and 12.5% in B-refined alloy at T6-treated conditions. In addition, the presence of more fine dimples on the fracture surfaces of the T6-treated specimens revealed that T6-treatment encourages ductile mode of fracture.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 7

- Cited by