Article contents

Influence of different casting processes on high cycle fatigue behavior of Mg–10Gd–3Y–0.5Zr alloy

Published online by Cambridge University Press: 24 June 2016

Abstract

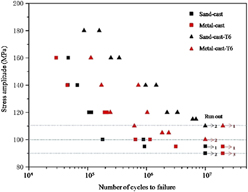

In this present study, the influence of different casting processes on high cycle fatigue behavior of Mg–10Gd–3Y–0.5Zr magnesium alloy was investigated by using porosity-free low-pressure sand-casting (LPS) bars and gravity permanent mold casting (GPM) ingots. The results show that the fatigue properties of both LPS and GPM Mg–10Gd–3Y–0.5Zr alloy in as-cast condition are determined by Mg matrix and eutectic phase. However, the fatigue property improvement for LPS alloy by T6 heat treatment is significantly superior to that of GPM alloy. The different degree of enhancement of fatigue properties for two conditions of the alloy is related to different crack initiation mechanism. The fatigue crack of the LPS alloy initiates from the free surface of the sample, while the crack of the GPM alloy initiates from porosities or inclusions near the surface of the sample. Meanwhile, the crack of slip band has a crucial effect on the fatigue crack initiation of both as-cast and T6 conditions for LPS alloy.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 4

- Cited by