Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wang, Shuaijun

He, Fengting

Dong, Pei

Tai, Zhaoxin

Zhao, Chaocheng

Wang, Yongqiang

Liu, Fang

and

Li, Lin

2018.

Simultaneous morphology, band structure, and defect optimization of graphitic carbon nitride microsphere by the precursor concentration to boost photocatalytic activity.

Journal of Materials Research,

Vol. 33,

Issue. 23,

p.

3917.

Wang, Mengjun

Liu, Chao

Zhang, Xiaobo

Fan, Zichun

Xu, Jiasheng

and

Tong, Zhiwei

2018.

In situ synthesis of CsTi2NbO7@g-C3N4 core–shell heterojunction with excellent electrocatalytic performance for the detection of nitrite.

Journal of Materials Research,

Vol. 33,

Issue. 23,

p.

3936.

Song, Yiming

Li, Jun

and

Wang, Chen

2018.

Modification of porphyrin/dipyridine metal complexes on the surface of TiO2 nanotubes with enhanced photocatalytic activity for photoreduction of CO2 into methanol.

Journal of Materials Research,

Vol. 33,

Issue. 17,

p.

2612.

Wang, Jie

Ren, LiZhen

Zhang, DongEn

Hao, XiaoYun

Gong, JunYan

Xiao, Xin

Jiang, YouXiang

and

Tong, ZhiWei

2018.

Fabrication of Bi2MoO6/BiOI heterojunction photocatalysts for enhanced photodegradation of RhB.

Journal of Materials Research,

Vol. 33,

Issue. 23,

p.

3928.

Liu, Shuilian

Chen, Jianlin

Xu, Difa

Zhang, Xiangchao

and

Shen, Mengyao

2018.

Enhanced photocatalytic activity of directZ-scheme Bi2O3/g-C3N4composites via facile one-step fabrication.

Journal of Materials Research,

Vol. 33,

Issue. 10,

p.

1391.

Kumar, Santosh

Karthikeyan, Sekar

and

Lee, Adam

2018.

g-C3N4-Based Nanomaterials for Visible Light-Driven Photocatalysis.

Catalysts,

Vol. 8,

Issue. 2,

p.

74.

Jiang, Xiaole

Ma, Yueying

Zhao, Chunran

Chen, Yijing

Cui, Min

Yu, Jingxiong

Wu, Ying

and

He, Yiming

2018.

Synthesis of flower-like AgI/Bi5O7I hybrid photocatalysts with enhanced photocatalytic activity in rhodamine B degradation.

Journal of Materials Research,

Vol. 33,

Issue. 16,

p.

2385.

Shen, Meng

Zhang, Lingxia

and

Shi, Jianlin

2018.

Converting CO2 into fuels by graphitic carbon nitride-based photocatalysts.

Nanotechnology,

Vol. 29,

Issue. 41,

p.

412001.

Qiao, Qing

Yang, Ke

Ma, Li-Li

Huang, Wei-Qing

Zhou, Bing-Xin

Pan, Anlian

Hu, Wangyu

Fan, Xiaoxing

and

Huang, Gui-Fang

2018.

Facile in situ construction of mediator-free direct Z-scheme g-C3N4/CeO2 heterojunctions with highly efficient photocatalytic activity.

Journal of Physics D: Applied Physics,

Vol. 51,

Issue. 27,

p.

275302.

Wang, Yunke

Hu, Shaozheng

Li, Qiang

Gu, Guizhou

Zhao, Yanfeng

Liang, Hongyu

and

Li, Wei

2018.

One step synthesis of high-efficiency AgBr–Br–g-C3N4 composite catalysts for photocatalytic H2O2 production via two channel pathway.

RSC Advances,

Vol. 8,

Issue. 64,

p.

36903.

Ma, Yunfeng

Yang, Lili

Yang, Yong

Peng, Yusi

Wei, Yuquan

and

Huang, Zhengren

2018.

Multifunctional Ag-decorated g-C3N4 nanosheets as recyclable SERS substrates for CV and RhB detection.

RSC Advances,

Vol. 8,

Issue. 39,

p.

22095.

Wang, Meng

Peng, Zhijian

Li, Hong

Zhao, Zengying

and

Fu, Xiuli

2018.

C fibers@MoO2 nanoparticles core–shell composite: Highly efficient solar-driven photocatalyst.

Journal of Materials Research,

Vol. 33,

Issue. 6,

p.

685.

Zhang, Peng

Dong, Zhiyuan

Ran, Yuanming

Xie, Hualin

Lu, Yun

and

Ding, Shimin

2018.

Preparation and photocatalytic application of AgBr modified Bi2WO6 nanosheets with high adsorption capacity.

Journal of Materials Research,

Vol. 33,

Issue. 23,

p.

3953.

Liu, Xingqi

and

Cai, Li

2018.

Novel indirect Z-scheme photocatalyst of Ag nanoparticles and polymer polypyrrole co-modified BiOBr for photocatalytic decomposition of organic pollutants.

Applied Surface Science,

Vol. 445,

Issue. ,

p.

242.

Xue, Shengyang

Wu, Chunzheng

Pu, Shengyan

Hou, Yaqi

Tong, Tian

Yang, Guang

Qin, Zhaojun

Wang, Zhiming

and

Bao, Jiming

2019.

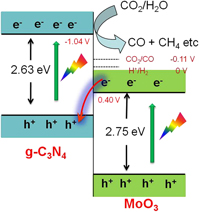

Direct Z-Scheme charge transfer in heterostructured MoO3/g-C3N4 photocatalysts and the generation of active radicals in photocatalytic dye degradations.

Environmental Pollution,

Vol. 250,

Issue. ,

p.

338.

Zhu, Xiaodi

and

Sun, Song

2019.

Nanophotocatalysis and Environmental Applications.

Vol. 31,

Issue. ,

p.

67.

Chen, Pengfei

Xing, Pingxing

Chen, Zhiqiang

Hu, Xin

Lin, Hongjun

Zhao, Leihong

and

He, Yiming

2019.

In-situ synthesis of AgNbO3/g-C3N4 photocatalyst via microwave heating method for efficiently photocatalytic H2 generation.

Journal of Colloid and Interface Science,

Vol. 534,

Issue. ,

p.

163.

Ma, Yajuan

Wang, Heng

Yu, Junchen

Mo, Wanling

and

Yuan, Hong

2019.

Synergetic effect of carbon self-doping and TiO2 deposition on boosting the visible-light photocatalytic hydrogen production efficiency of carbon nitride.

International Journal of Hydrogen Energy,

Vol. 44,

Issue. 12,

p.

5881.

Nguyen, Chinh-Chien

Sakar, M.

Vu, Manh-Hiep

and

Do, Trong-On

2019.

Nitrogen Vacancies-Assisted Enhanced Plasmonic Photoactivities of Au/g-C3N4 Crumpled Nanolayers: A Novel Pathway toward Efficient Solar Light-Driven Photocatalysts.

Industrial & Engineering Chemistry Research,

Vol. 58,

Issue. 9,

p.

3698.

Ghosh, Utpal

and

Pal, Anjali

2019.

Graphitic carbon nitride based Z scheme photocatalysts: Design considerations, synthesis, characterization and applications.

Journal of Industrial and Engineering Chemistry,

Vol. 79,

Issue. ,

p.

383.