Article contents

Hexagonal close-packed high-entropy alloy formation under extreme processing conditions

Published online by Cambridge University Press: 22 January 2019

Abstract

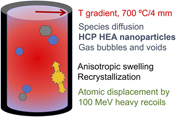

We assess the validity of criteria based on size mismatch and thermodynamics in predicting the stability of the rare class of high-entropy alloys (HEAs) that form in the hexagonal close-packed crystal structure. We focus on nanocrystalline HEA particles composed predominantly of Mo, Tc, Ru, Rh, and Pd along with Ag, Cd, and Te, which are produced in uranium dioxide fuel under the extreme conditions of nuclear reactor operation. The constituent elements are fission products that aggregate under the combined effects of irradiation and elevated temperature as high as 1200 °C. We present the recent results on alloy nanoparticle formation in irradiated ceria, which was selected as a surrogate for uranium dioxide, to show that radiation-enhanced diffusion plays an important role in the process. This work sheds light on the initial stages of alloy nanoparticle formation from a uniform dispersion of individual metals. The remarkable chemical durability of such multiple principal element alloys presents a solution, namely, an alloy waste form, to the challenge of immobilizing Tc.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 34 , Issue 5: Focus Issue: Nanocrystalline High Entropy Materials: Processing Challenges and Properties , 14 March 2019 , pp. 709 - 719

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

This work was performed while M.A. Conroy was at Pacific Northwest National Laboratory.

References

- 8

- Cited by