Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Yuan, Lu

Yin, Qiyue

Wang, Yiqian

and

Zhou, Guangwen

2013.

CuO reduction induced formation of CuO/Cu2O hybrid oxides.

Chemical Physics Letters,

Vol. 590,

Issue. ,

p.

92.

Yuan, Lu

Cai, Rongsheng

Jang, Joon I.

Zhu, Wenhui

Wang, Chao

Wang, Yiqian

and

Zhou, Guangwen

2013.

Morphological transformation of hematite nanostructures during oxidation of iron.

Nanoscale,

Vol. 5,

Issue. 16,

p.

7581.

Yuan, Lu

Wang, Chao

Cai, Rongsheng

Wang, Yiqian

and

Zhou, Guangwen

2013.

Spontaneous ZnO nanowire formation during oxidation of Cu-Zn alloy.

Journal of Applied Physics,

Vol. 114,

Issue. 2,

Zhao, C. X.

Li, Y. F.

Zhou, J.

Li, L. Y.

Deng, S. Z.

Xu, N. S.

and

Chen, Jun

2013.

Large-Scale Synthesis of Bicrystalline ZnO Nanowire Arrays by Thermal Oxidation of Zinc Film: Growth Mechanism and High-Performance Field Emission.

Crystal Growth & Design,

Vol. 13,

Issue. 7,

p.

2897.

Zhu, Jian

Ng, K. Y. Simon

and

Deng, Da

2014.

Micro Single Crystals of Hematite with Nearly 100% Exposed {104} Facets: Preferred Etching and Lithium Storage.

Crystal Growth & Design,

Vol. 14,

Issue. 6,

p.

2811.

Lin, Dong

Deng, Biwei

Sassman, Stephen A.

Hu, Yaowu

Suslov, Sergey

and

Cheng, Gary J.

2014.

Magnetic field assisted growth of highly dense α-Fe2O3 single crystal nanosheets and their application in water treatment.

RSC Adv.,

Vol. 4,

Issue. 36,

p.

18621.

Yuan, Lu

Wang, Chao

Cai, Rongsheng

Wang, Yiqian

and

Zhou, Guangwen

2014.

Temperature-dependent growth mechanism and microstructure of ZnO nanostructures grown from the thermal oxidation of zinc.

Journal of Crystal Growth,

Vol. 390,

Issue. ,

p.

101.

Zhu, Huihui

Deng, Jinxia

Chen, Jun

Yu, Ranbo

and

Xing, Xianran

2014.

Growth of hematite nanowire arrays during dense pentlandite oxidation.

Journal of Materials Chemistry A,

Vol. 2,

Issue. 9,

p.

3008.

Deng, Da

2015.

Li‐ion batteries: basics, progress, and challenges.

Energy Science & Engineering,

Vol. 3,

Issue. 5,

p.

385.

Kotenev, V. A.

Kiselev, M. R.

Vysotskii, V. V.

Averin, A. A.

and

Tsivadze, A. Yu.

2016.

The formation of urchinlike nanostructures under thermal oxidation and depassivation of iron particles.

Protection of Metals and Physical Chemistry of Surfaces,

Vol. 52,

Issue. 5,

p.

825.

Zhu, Wenhui

Winterstein, Jonathan P

Sharma, Renu

and

Zhou, Guangwen

2016.

The Growth of Catalyst-free NiO Nanowires.

Microscopy and Microanalysis,

Vol. 22,

Issue. S3,

p.

1620.

Zhu, Wenhui

Winterstein, Jonathan

Maimon, Itai

Yin, Qiyue

Yuan, Lu

Kolmogorov, Aleksey N.

Sharma, Renu

and

Zhou, Guangwen

2016.

Atomic Structural Evolution during the Reduction of α-Fe2O3 Nanowires.

The Journal of Physical Chemistry C,

Vol. 120,

Issue. 27,

p.

14854.

Feng, Honglei

Wang, Yiqian

Wang, Chao

Diao, Feiyu

Zhu, Wenhui

Mu, Peng

Yuan, Lu

Zhou, Guangwen

and

Rosei, Federico

2016.

Defect-induced enhanced photocatalytic activities of reducedα-Fe2O3nanoblades.

Nanotechnology,

Vol. 27,

Issue. 29,

p.

295703.

Zhu, Wenhui

Winterstein, Jonathan P.

Yang, Wei-Chang David

Yuan, Lu

Sharma, Renu

and

Zhou, Guangwen

2017.

In Situ Atomic-Scale Probing of the Reduction Dynamics of Two-Dimensional Fe2O3 Nanostructures.

ACS Nano,

Vol. 11,

Issue. 1,

p.

656.

Kotenev, V. A.

2018.

Regularities of Vacuum Oxidation of Iron in the Range of Low-Temperature Passivation According to the Data of Spectral Ellipsometry.

Protection of Metals and Physical Chemistry of Surfaces,

Vol. 54,

Issue. 5,

p.

969.

Zhu, Jian

and

Deng, Da

2018.

Anisotropic Particle Assemblies.

p.

261.

Sun, Xianhu

Zhu, Wenhui

Wu, Dongxiang

Liu, Zhenyu

Chen, Xiaobo

Yuan, Lu

Wang, Guofeng

Sharma, Renu

and

Zhou, Guangwen

2020.

Atomic‐Scale Mechanism of Unidirectional Oxide Growth.

Advanced Functional Materials,

Vol. 30,

Issue. 4,

Zhu, Dingding

Wang, Xinli

Zhao, Jun

Lu, Jian

Zhou, Yichun

Cai, Canying

Huang, Jianyu

and

Zhou, Guangwen

2020.

Effect of water vapor on high-temperature oxidation of NiAl alloy.

Corrosion Science,

Vol. 177,

Issue. ,

p.

108963.

Lai, Ming-Wei

and

Kurata, Hiroki

2021.

Exploring (1$$\overline{1}$$2)-related ordered structure in oxidation-synthesized α-Fe2O3 nanowhiskers.

Journal of Materials Science,

Vol. 56,

Issue. 12,

p.

7286.

Lee, Seonyong

and

Jang, Ho Won

2021.

α-Fe2O3 nanostructure-based gas sensors.

JOURNAL OF SENSOR SCIENCE AND TECHNOLOGY,

Vol. 30,

Issue. 4,

p.

210.

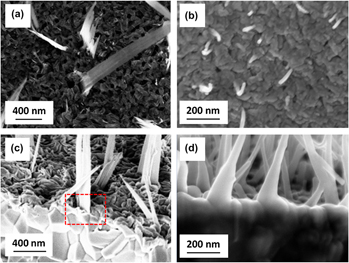

direction with a bicrystal structure. It is shown that nanowires are rooted on Fe2O3 grains, whereas nanobelts are originated from the boundaries of Fe2O3 grains. Our results show that oxygen gas pressure can be used to manipulate the Fe2O3/Fe3O4 interfacial reaction, thereby tailoring the oxide growth morphologies via the stress-driven diffusion.

direction with a bicrystal structure. It is shown that nanowires are rooted on Fe2O3 grains, whereas nanobelts are originated from the boundaries of Fe2O3 grains. Our results show that oxygen gas pressure can be used to manipulate the Fe2O3/Fe3O4 interfacial reaction, thereby tailoring the oxide growth morphologies via the stress-driven diffusion.