Article contents

Gradient microstructure and texture in wedge-based severe plastic burnishing of copper

Published online by Cambridge University Press: 27 April 2018

Abstract

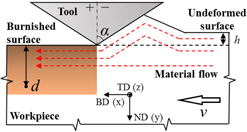

In the present study, gradient microstructure and texture development in wedge-based severe plastic burnishing of oxygen-free high conductivity copper was investigated. Microstructural response and evolution of crystallographic texture in severe surface plastic deformation was shown to be controllable in terms of both magnitude and gradient through control of the incident wedge angle and burnishing parameters. Equiaxed ultra-fined grains and micro/nanoscale elongated grains were produced in the subsurface region, which is indicative of dynamic recrystallization at large strains in the subsurface. Subsurface regions exhibited a significant fraction of shear texture components along the 〈110〉 partial fibers. Texture evolution simulated using the visco-plastic self-consistent framework revealed variations in strain level controlling different mechanisms for rotation of these partial fibers from their ideal orientation. Controllability of subsurface properties and microstructure for such materials is briefly discussed. These results allude to fundamental limits in material processing by severe shear using scalable deformation configurations.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 5

- Cited by