Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Barber, Helena

Kelly, Cambre N.

Nelson, Kaitlin

and

Gall, Ken

2021.

Compressive anisotropy of sheet and strut based porous Ti–6Al–4V scaffolds.

Journal of the Mechanical Behavior of Biomedical Materials,

Vol. 115,

Issue. ,

p.

104243.

Beloshenko, Victor

Beygelzimer, Yan

Chishko, Vyacheslav

Savchenko, Bogdan

Sova, Nadiya

Verbylo, Dmytro

Voznyak, Andrei

and

Vozniak, Iurii

2021.

Mechanical Properties of Flexible TPU-Based 3D Printed Lattice Structures: Role of Lattice Cut Direction and Architecture.

Polymers,

Vol. 13,

Issue. 17,

p.

2986.

Deering, Joseph

Presas, Alexandre

Yu, Bosco

Valentin, David

Heiss, Christian

Bosbach, Wolfram A.

and

Grandfield, Kathryn

2021.

Implant resonance and the mechanostat theory: Applications of therapeutic ultrasound for porous metallic scaffolds.

Materials Science and Engineering: C,

Vol. 125,

Issue. ,

p.

112070.

Kelly, Cambre N.

Kahra, C.

Maier, Hans J.

and

Gall, Ken

2021.

Processing, structure, and properties of additively manufactured titanium scaffolds with gyroid-sheet architecture.

Additive Manufacturing,

Vol. 41,

Issue. ,

p.

101916.

Nelson, Kaitlin

Kelly, Cambre N.

and

Gall, Ken

2022.

Effect of stress state on the mechanical behavior of 3D printed porous Ti6Al4V scaffolds produced by laser powder bed fusion.

Materials Science and Engineering: B,

Vol. 286,

Issue. ,

p.

116013.

Hou, Chenjin

Liu, Yitong

Xu, Wei

Lu, Xin

Guo, Lijia

Liu, Yi

Tian, Shiwei

Liu, Bowen

Zhang, Jiazhen

and

Wen, Cuie

2022.

Additive manufacturing of functionally graded porous titanium scaffolds for dental applications.

Biomaterials Advances,

Vol. 139,

Issue. ,

p.

213018.

Peloquin, Jacob

Kirillova, Alina

Rudin, Cynthia

Brinson, L.C.

and

Gall, Ken

2023.

Prediction of tensile performance for 3D printed photopolymer gyroid lattices using structural porosity, base material properties, and machine learning.

Materials & Design,

Vol. 232,

Issue. ,

p.

112126.

DEPBOYLU, Fatma Nur

POYRAZ, Özgür

YASA, Evren

and

KORKUSUZ, Feza

2023.

Lazer-Toz Yatağında Füzyon ile Üretilen Ti6Al4V Gyroid Yapıların Basma Dayanımlarının Nümerik Modellenmesi.

Afyon Kocatepe University Journal of Sciences and Engineering,

Vol. 23,

Issue. 1,

p.

270.

Dastani, Kia

Movahhedy, Mohammad R.

Yu, Hongyu

Khodaygan, Saeed

Zhang, Lei

and

Wang, Michael Yu

2023.

Effect of geometric deviations on the strength of additively manufactured ultralight periodic shell-based lattices.

Engineering Failure Analysis,

Vol. 150,

Issue. ,

p.

107328.

Suryawanshi, Chetana Madhukar

Sagar, Samrat

Bhallamudi, Ravi

and

Mishra, Sushil

2023.

Effective design and mechanical response of Gyroid lattice scaffold for orthopedic implants.

Manufacturing Letters,

Vol. 35,

Issue. ,

p.

493.

Khrapov, Dmitriy

Paveleva, Aleksandra

Kozadayeva, Maria

Evsevleev, Sergei

Mishurova, Tatiana

Bruno, Giovanni

Surmenev, Roman

Koptyug, Andrey

and

Surmeneva, Maria

2023.

Trapped powder removal from sheet-based porous structures based on triply periodic minimal surfaces fabricated by electron beam powder bed fusion.

Materials Science and Engineering: A,

Vol. 862,

Issue. ,

p.

144479.

Hitchon, Sydney

Soltanmohammadi, Pendar

Milner, Jaques S.

Holdsworth, David

and

Willing, Ryan

2024.

Porous versus solid shoulder implants in humeri of different bone densities: A finite element analysis.

Journal of Orthopaedic Research,

Mathey, Elizabeth

Heimbrook, Amanda

Carpenter, R. D.

Kelly, Cambre N.

and

Gall, Ken

2024.

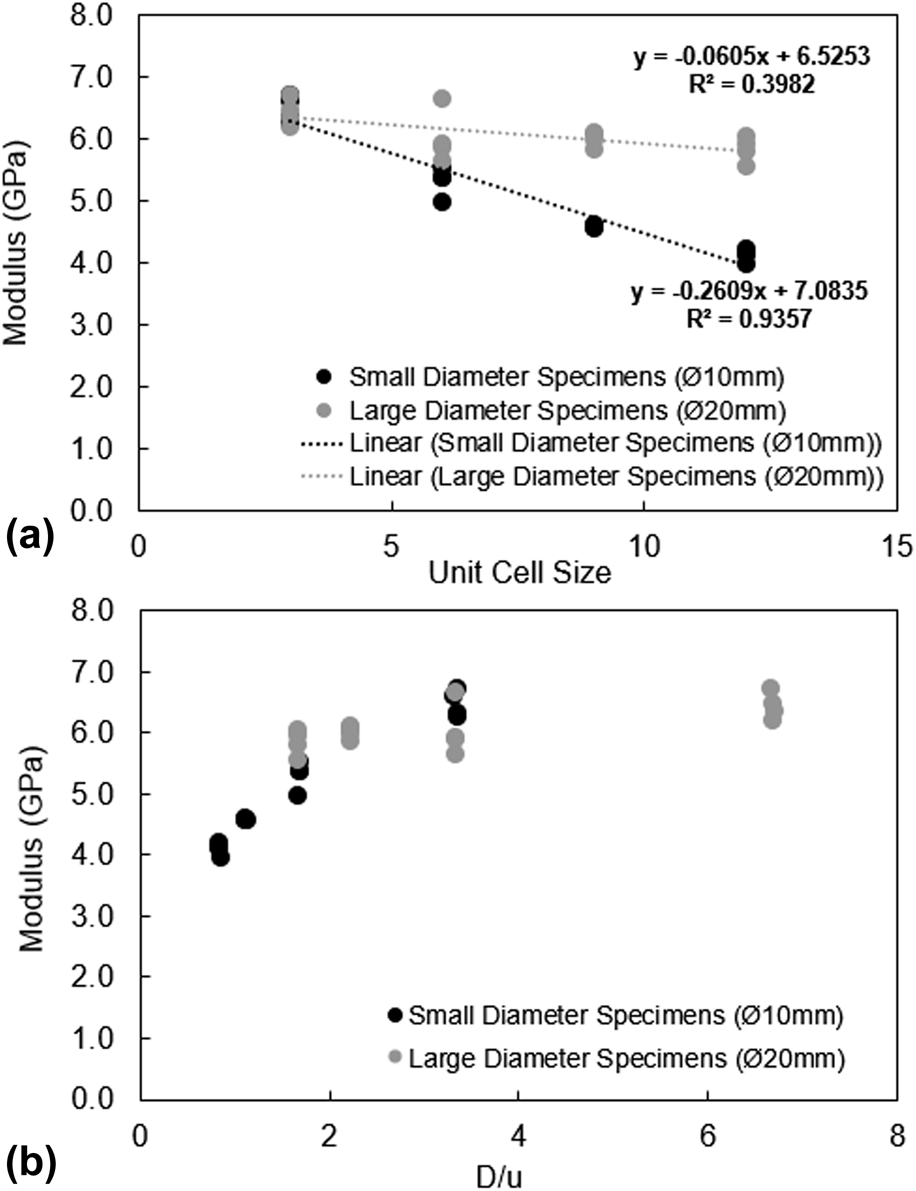

Finite element modeling of the free boundary effect on gyroid additively manufactured samples.

Computer Methods in Biomechanics and Biomedical Engineering,

p.

1.

López-Barroso, Juventino

Flores-Hernández, Cynthia Graciela

Martínez-Hernández, Ana Laura

Martínez-Barrera, Gonzalo

and

Velasco-Santos, Carlos

2024.

Advanced Composites.

p.

121.