Article contents

Flow behavior and processing map of forging commercial purity titanium powder compact

Published online by Cambridge University Press: 13 April 2015

Abstract

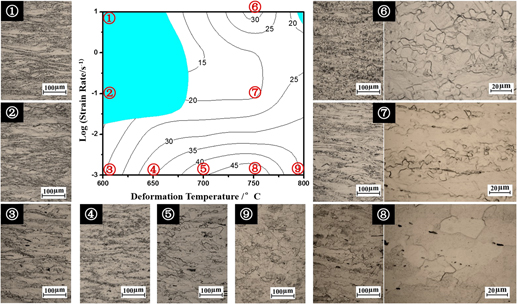

The flow behavior of forged commercial purity (CP) titanium powder compact was studied by developing a processing map. CP titanium powder was sintered to 94% relative density, then hot compressed in a Gleeble thermal–mechanical simulator at strain rates ranging from 0.001 to 10 s−1 and deformation temperatures ranging from 600 to 800 °C. The hot forging process improved the densification to 98–99.9% and reduced the grain size from 93 to 10 µm by the occurrence of dynamic recrystallization. The fully dynamic recrystallization region is in the range of deformation temperature of 750–800 °C and strain rate of 0.001–0.01 s−1, with a power dissipation efficiency higher than 40%, determined by constructing a processing map and analyzing the volume fraction of dynamic recrystallization. This research provides a guide for powder compact forging of power metallurgy titanium by providing the hot compression parameters, which can lead to an improved microstructure and densification.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 4

- Cited by