Article contents

Fabrication of nanoperforated ultrathin TiO2 films by inkjet printing

Published online by Cambridge University Press: 14 July 2015

Abstract

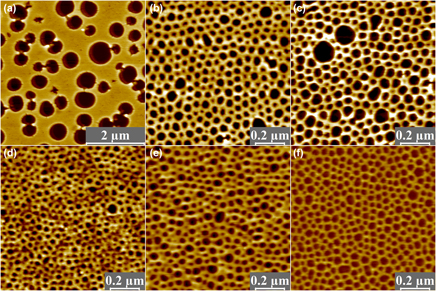

Fabrication of nanoperforated TiO2 thin films (NP-TiO2) on various substrates utilizing evaporation-induced self-assembly has been widely reported during recent years. For many applications, such as solar cells and gas sensors, it would be beneficial if the active material could be deposited onto a desired area or in the form of a pattern or array. In this study, inkjet printing was successfully used to produce NP-TiO2 at both ambient temperature and 60 °C. Especially for intermediate drop spacings (40 and 50 µm), millimeter-sized homogeneous NP-TiO2 patches were obtained with similar NP structure as those being processed by dip coating and drop casting. Compared to ambient temperature, inkjet printing at 60 °C provides a narrower height distribution of the NP structures of about 5 nm. Compared to dip coating and drop casting, inkjet printing enables the deposition of the ink onto target areas, thus enabling the fabrication of microscale arrays and other patterned structures.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 4

- Cited by