Article contents

Effects of minor Cu and Mg additions on microstructure and material properties of 8xxx aluminum conductor alloys

Published online by Cambridge University Press: 08 March 2017

Abstract

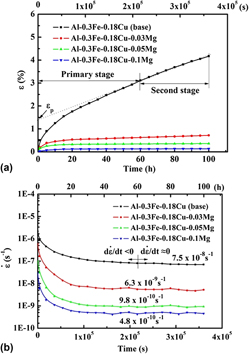

The effects of minor Cu (0–0.29 wt%) and Mg (0–0.1 wt%) additions on the microstructure, electrical conductivity, mechanical, and creep properties of 8xxx aluminum conductor alloys were studied. The microstructure evolution was investigated using an optical microscope and the electron backscattered diffraction technique. The creep property was characterized by the primary creep strain and the minimum creep rate during creep deformation. The results demonstrated that additions of minor Cu and Mg reasonably improved the ultimate tensile strength but slightly reduced electrical conductivity. The addition of Cu remarkably decreased the primary creep strain but had a negligible effect on the minimum creep rate, leading to a beneficial effect on the short-term creep resistance but no advantage to the creep resistance under the long-term creep process. The minor addition of Mg greatly reduces both the primary creep strain and minimum creep rate, resulting in a significant and effective improvement in the creep resistance.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 11

- Cited by