Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Chen, Antao

Wu, Guohua

Zhang, Liang

Zhang, Xiaolong

Shi, Chunchang

and

Li, Yanlei

2016.

Microstructural characteristics and mechanical properties of cast Al-3Li-xCu-0.2Zr alloy.

Materials Science and Engineering: A,

Vol. 677,

Issue. ,

p.

29.

Shi, Chunchang

Zhang, Liang

Wu, Guohua

Zhang, Xiaolong

Chen, Antao

and

Tao, Jiashen

2017.

Effects of Sc addition on the microstructure and mechanical properties of cast Al-3Li-1.5Cu-0.15Zr alloy.

Materials Science and Engineering: A,

Vol. 680,

Issue. ,

p.

232.

Fan, Shitong

Deng, Yunlai

Zhang, Yong

Huang, Xinyue

and

Zhang, Xinming

2018.

Homogenization of 7050 plates by a novel differential temperature rolling.

Materials and Manufacturing Processes,

Vol. 33,

Issue. 16,

p.

1822.

Shi, Chunchang

Wu, Guohua

Zhang, Liang

and

Zhang, Xiaolong

2018.

Al–5.5Mg–1.5Li–0.5Zn–0.07Sc–0.07Zr alloy produced by gravity casting and heat treatment processing.

Materials and Manufacturing Processes,

Vol. 33,

Issue. 8,

p.

891.

Yuan, Ting

Jiang, Jinghua

Wu, Yuna

Yuan, Zhipeng

Ma, Aibin

and

Yuan, Yuchun

2019.

Cooperative Effect of Li Content and Equal-Channel Angular Pressing on Microstructure and Mechanical Properties of Al-Mg-Li Alloy.

Metals,

Vol. 9,

Issue. 8,

p.

840.

Yang, Ruibin

Yang, Junrui

Xie, Kun

Liu, Zhongxia

and

Zhang, Guotao

2019.

Investigation of micro-yield strength and coefficient of thermal expansion of Al–Cu–Mg–Li–Sc–Ag alloys with various contents of Li.

Journal of Materials Research,

Vol. 34,

Issue. 15,

p.

2714.

Zeng, Wen

Qin, Weicai

Gu, Cheng

Sun, Hao

Ma, Yilong

and

Cao, Xianlong

2019.

Microstructure and properties of pure aluminum prepared by spark plasma sintering.

Metallurgical Research & Technology,

Vol. 116,

Issue. 3,

p.

312.

Jandaghi, M.R.

Badini, C.

and

Pavese, M.

2020.

Dissimilar friction stir welding of AA2198 and AA7475: Effect of solution treatment and aging on the microstructure and mechanical strength.

Journal of Manufacturing Processes,

Vol. 57,

Issue. ,

p.

712.

Chen, Xiaoxue

Ma, Xinwu

Xi, Huakun

Zhao, Guoqun

Wang, Yongxiao

and

Xu, Xiao

2020.

Effects of heat treatment on the microstructure and mechanical properties of extruded 2196 Al-Cu-Li alloy.

Materials & Design,

Vol. 192,

Issue. ,

p.

108746.

Zhang, Xuejian

Wang, Hongwei

Yan, Bing

Zou, Chunming

and

Wei, Zunjie

2021.

The effect of grain refinement and precipitation strengthening induced by Sc or Er alloying on the mechanical properties of cast Al-Li-Cu-Mg alloys at elevated temperatures.

Materials Science and Engineering: A,

Vol. 822,

Issue. ,

p.

141641.

Shi, Chunchang

Wu, Guohua

Zhang, Liang

Zhang, Xiaolong

Sun, Jiangwei

Zhang, Jinshuo

and

Wang, Yixiao

2021.

Variation in the microstructure and mechanical properties of permanent mold cast Al–3Li–2Mg–0.1Zr alloy with Zn addition.

Journal of Materials Research,

Vol. 36,

Issue. 10,

p.

2071.

Sun, Zeyu

Tian, Xiangjun

He, Bei

Li, Zhuo

and

Tang, Haibo

2021.

Microstructure evolution and microhardness of the novel Al–Cu–Li-xSc alloys fabricated by laser rapid melting.

Vacuum,

Vol. 189,

Issue. ,

p.

110235.

Yogesha, K. K.

Joshi, Amit

Raja, A.

Jayaganthan, R.

and

Verma, Raviraj

2023.

Effect of Different Rolling Techniques on Fatigue Crack Propagation in 5052 Al Alloy.

Metallography, Microstructure, and Analysis,

Vol. 12,

Issue. 1,

p.

62.

Zhang, Shuo

Qi, Fangzhou

Zhang, Liang

Wu, Guohua

Tong, Xin

Zhan, Junmin

Wang, Yan

and

Geng, Yingjing

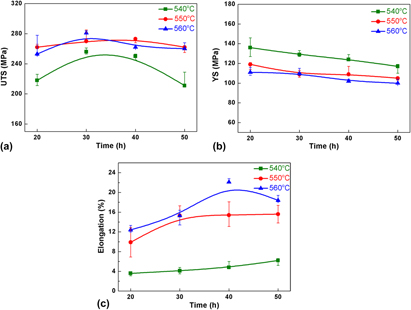

2024.

Effect of aging treatment on high temperature mechanical properties of a cast Al–Li–Cu alloy.

Materials Science and Engineering: A,

Vol. 896,

Issue. ,

p.

146300.