Article contents

Effect of growth rate on microstructures and microhardness in directionally solidified Ti–47Al–1.0W–0.5Si alloy

Published online by Cambridge University Press: 22 February 2016

Abstract

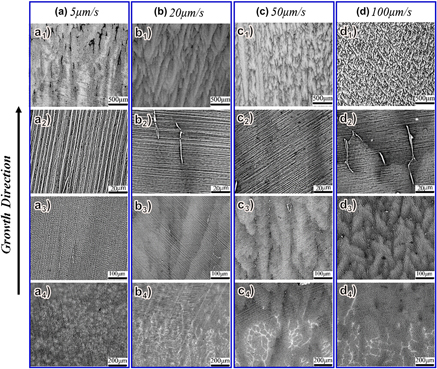

Ti–47Al–1.0W–0.5Si (at.%) alloy was directionally solidified in the range of growth rate (V) (V = 3–100 μm/s) at a constant temperature gradient (G = 18 K/mm). It was found that α phase was the primary phase of the alloy. Both primary dendritic arm spacing (λ) and interlamellar spacing (λs) decreased with increase of the growth rate (V) according to the relationship of λ ∝ V

−0.356 and λs ∝ V

−0.49, respectively. The Solidification segregation occurred since the enrichment of the solute element W in primary α phase during solidification. The degree of the segregation increased with the increase of the growth rate (V). The results also revealed that the lamellar orientation was not always perpendicular to the growth direction (GD) because the GD of primary α dendritic deviated from the preferred

$\left\langle {0001} \right\rangle$

direction. The microhardness increased with increasing growth rate (V) according to H

V ∝ 289.5V

0.12 because of the microstructure refinement.

$\left\langle {0001} \right\rangle$

direction. The microhardness increased with increasing growth rate (V) according to H

V ∝ 289.5V

0.12 because of the microstructure refinement.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 3

- Cited by