Article contents

Effect of ferrite grain size on the estimated true stress–true strain relationship up to the plastic deformation limit in low carbon ferrite–cementite steels

Published online by Cambridge University Press: 13 August 2013

Abstract

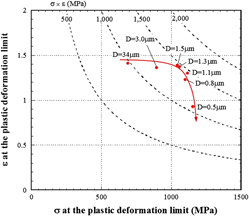

Grain refinement strengthening in low carbon ferrite–cementite steel was investigated using the estimated true stress (σ)–true strain (ε) relationship up to the plastic deformation limit, i.e., just before fracture. Static and stepwise tensile tests were performed using ferrite–cementite (FC) steels with ferrite grain sizes in the range 0.5–34 μm, and the σ–ε relationships up to the plastic deformation limit were estimated by using the Bridgman equation. In the nominal stress–strain curves, the lower yield stress and tensile strength increased and the uniform and total elongations decreased with a decrease in the ferrite grain size. It was found from the σ–ε relationships of the FC steels that grain refinement strengthening up to 0.8 μm can improve σ and ε at the plastic deformation limit. From the scanning electron microscopy observations of the cross-sectional planes parallel to the tensile direction for the FC steels, voids were observed at the interface between ferrite and cementite in the case where the thickness of elongated ferrite came close to the size of the dispersed cementite.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 9

- Cited by