Article contents

Effect of a nanostructured surface layer on the tensile properties of 316L stainless steel

Published online by Cambridge University Press: 10 May 2013

Abstract

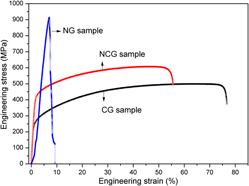

A nanostructured surface layer was fabricated in the surface of 316L stainless steel by a novel fast multiple rotation rolling (FMRR) technique. The microstructure and the tensile properties of the treated sample were investigated in detail. The experimental results indicate that a nanograined (NG) film was successfully obtained in the surface of the sample. Equiaxed nanograins with the average grain size of about 12 nm are achieved in the surface layer. At the sample time, deformation-induced α-martensite is produced during the FMRR treatment. The volume fraction of martensite is about 20%. The yield strength (0.2% offset) of the sample, of which one side is of NG structure and the other is coarse grained (CG), is increased by 51% in comparison with that of the CG sample. Though the plasticity is diminished slightly for the FMRR specimen, the elongation still reaches a high value of about 38% owing to the contribution of the CG structure.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 1

- Cited by