Article contents

Crystallographic analysis of nucleation for random orientations in high-purity tantalum

Published online by Cambridge University Press: 11 June 2018

Abstract

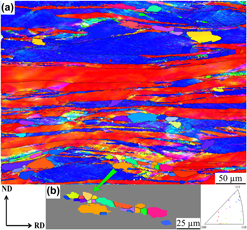

Strain path changes during clock rolling cause more serious interaction between adjacent grains, resulting in the occurrence of interactive regions (IRs) with random orientations. Furthermore, plenty of new grains with relatively random orientations are introduced by the subsequent annealing of these IRs. The morphology of the IR and the origin of random orientations were therefore investigated in this study, and the electron backscatter diffraction technique was used to characterize crystallographic orientations of nuclei and deformed matrices. A short-time annealing was imposed on a specimen to catch the transient nucleation behaviors. The results indicate that the orientations of nuclei are similar to their surrounding deformed matrices, especially the points with larger local-misorientation. Additionally, the shape of new grains depends on where it forms, and it is suggested that this fact mainly results from the great difference in stored energies between deformed matrices with {111} and {100} orientations.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 6

- Cited by