Article contents

A comparative analysis of sound absorption performance of ZL104/aluminum fiber composite foam

Published online by Cambridge University Press: 20 September 2019

Abstract

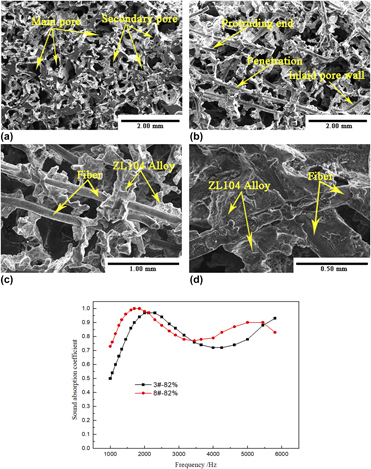

ZL104 alloy foam and ZL104 alloy/aluminum fiber composite foams with a porosity of 71–90% were prepared by an infiltration casting method. The pore structure and the sound absorption properties of these two kinds of foams were studied. The results show that fibers partially embedded in the porous pore walls and partially extending out of the pore in the composite foams. The sound absorption coefficient of the foams has a sound absorption peak and a sound absorption trough with increasing frequency. The fiber composite foam possesses better sound absorption properties compared with the alloy foam. As porosity, fiber diameter, and fiber content increases, the average sound absorption coefficient of the composite foam first increases and then decreases. The average sound absorption coefficient (0.88) of the composite foam with a fiber content of 5 vol%, a fiber diameter of 0.1 mm, and a porosity of 82% increased 10% compared with that of the alloy foam. The surface roughness and specific surface area of the foam increase after fiber compounding, and the sound wave drives the fibers to vibrate to enlarge the consumption of sound energy.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 6

- Cited by