Article contents

Bilayer graphene-covered Cu flexible electrode with excellent mechanical reliability and electrical performance

Published online by Cambridge University Press: 11 October 2019

Abstract

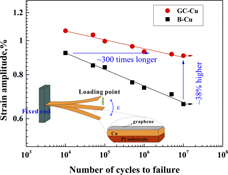

Flexible electrode is an indispensable component of emerging portable, flexible, and wearable electronic devices. Although various flexible electrodes with different dimensions and functions have been explored, developing a new electrode material with excellent mechanical reliability and superior electrical performance remains a challenge. Here, a graphene-covered Cu composite electrode film with a total thickness of ∼100 nm is successfully fabricated onto a flexible polyimide substrate by means of a series of assembly methods including physical vapor deposition, chemical vapor deposition, and transfer technique. The composite electrode film on the flexible substrate exhibits evidently enhanced tensile strength, monotonic bending, and repeatedly bending fatigue reliability as well as electrical performance compared with that of the bared Cu film electrode. Such excellent mechanical performances are attributed to the role of the graphene coating in suppressing fatigue damage formation and preventing crack advance. It is expected that the chemical vapor-deposited graphene-covered Cu composite electrode would extend the potential ultrathin metal film electrode as the innovative electrode material for the next-generation flexible electronic devices.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 4

- Cited by