Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Lidor‐Shalev, Ortal

Leifer, Nicole

Ejgenberg, Michal

Aviv, Hagit

Perelshtein, Ilana

Goobes, Gil

Noked, Malachi

and

Rosy

2021.

Molecular Layer Deposition of Alucone Thin Film on LiCoO2 to Enable High Voltage Operation.

Batteries & Supercaps,

Vol. 4,

Issue. 11,

p.

1739.

Meng, Xiangbo

Lau, Kah Chun

Zhou, Hua

Ghosh, Sujan Kumar

Benamara, Mourad

and

Zou, Min

2021.

Molecular Layer Deposition of Crosslinked Polymeric Lithicone for Superior Lithium Metal Anodes.

Energy Material Advances,

Vol. 2021,

Issue. ,

Liu, Yongqiang

Wang, Xin

Ghosh, Sujan Kumar

Zou, Min

Zhou, Hua

Xiao, Xianghui

and

Meng, Xiangbo

2022.

Atomic layer deposition of lithium zirconium oxides for the improved performance of lithium-ion batteries.

Dalton Transactions,

Vol. 51,

Issue. 7,

p.

2737.

Sullivan, Matthew

Tang, Peng

and

Meng, Xiangbo

2022.

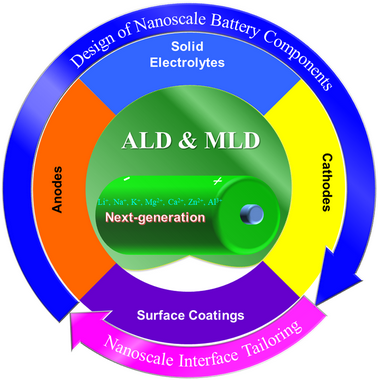

Atomic and Molecular Layer Deposition as Surface Engineering Techniques for Emerging Alkali Metal Rechargeable Batteries.

Molecules,

Vol. 27,

Issue. 19,

p.

6170.

Zuo, Lanlan

Lu, Di

Yang, Tianyan

Yue, Dan

Li, Weidong

Ma, Qiang

Chen, Yufang

Zheng, Chunman

and

Wu, Xiongwei

2022.

Recent achievements of free‐standing material and interface optimization in high‐energy‐density flexible lithium batteries.

Carbon Neutralization,

Vol. 1,

Issue. 3,

p.

316.

Wang, Xin

Cai, Jiyu

Ren, Yang

Benamara, Mourad

Zhou, Xinwei

Li, Yan

Chen, Zonghai

Zhou, Hua

Xiao, Xianghui

Liu, Yuzi

and

Meng, Xiangbo

2022.

High-performance LiNi0.8Mn0.1Co0.1O2 cathode by nanoscale lithium sulfide coating via atomic layer deposition.

Journal of Energy Chemistry,

Vol. 69,

Issue. ,

p.

531.

Østli, Elise R.

Ebadi, Mahsa

Tesfamhret, Yonas

Mahmoodinia, Mehdi

Lacey, Matthew J.

Brandell, Daniel

Svensson, Ann Mari

Selbach, Sverre M.

and

Wagner, Nils P.

2022.

On the Durability of Protective Titania Coatings on High‐Voltage Spinel Cathodes.

ChemSusChem,

Vol. 15,

Issue. 12,

Utke, I.

Swiderek, P.

Höflich, K.

Madajska, K.

Jurczyk, J.

Martinović, P.

and

Szymańska, I.B.

2022.

Coordination and organometallic precursors of group 10 and 11: Focused electron beam induced deposition of metals and insight gained from chemical vapour deposition, atomic layer deposition, and fundamental surface and gas phase studies.

Coordination Chemistry Reviews,

Vol. 458,

Issue. ,

p.

213851.

Multia, Jenna

and

Karppinen, Maarit

2022.

Atomic/Molecular Layer Deposition for Designer's Functional Metal–Organic Materials.

Advanced Materials Interfaces,

Vol. 9,

Issue. 15,

Zhang, Shuoqing

Andreas, Nicolai Sage

Li, Ruhong

Zhang, Nan

Sun, Chuangchao

Lu, Di

Gao, Tao

Chen, Lixin

and

Fan, Xiulin

2022.

Mitigating irreversible capacity loss for higher-energy lithium batteries.

Energy Storage Materials,

Vol. 48,

Issue. ,

p.

44.

Lee, Minji

Ahmad, Waheed

Kim, Dae Woong

Kwon, Kyu Moon

Kwon, Ha Yeon

Jang, Han-Bin

Noh, Seung-Won

Kim, Dae-Ho

Zaidi, Syed Jazib Abbas

Park, Hwiyeol

Lee, Heung Chan

Abdul Basit, Muhammad

and

Park, Tae Joo

2022.

Powder Coatings via Atomic Layer Deposition for Batteries: A Review.

Chemistry of Materials,

Vol. 34,

Issue. 8,

p.

3539.

Wang, Xin

and

Meng, Xiang-Bo

2023.

Surface modifications of layered LiNixMnyCozO2 cathodes via atomic and molecular layer deposition.

Rare Metals,

Vol. 42,

Issue. 7,

p.

2121.

Chang, Sheng Hsiung

Meng, Xiangbo

Liu, Jian

Tsai, Dung-Sheng

Wang, Xinwei

Chuang, Chiashain

Chen, Cheng-Ying

and

Li, Aidong

2023.

Editorial for focus on manipulations of atomic and molecular layers and its applications in energy, environment sciences and optoelectronic devices.

Nanotechnology,

Vol. 34,

Issue. 50,

p.

500201.

Jain, Hardik

Creatore, Mariadriana

and

Poodt, Paul

2023.

Molecular layer deposition of alucone in high aspect ratio trenches: The effect of TMA outgassing on step-coverage.

Journal of Vacuum Science & Technology A,

Vol. 41,

Issue. 1,

Meng, Xiangbo

and

Chen, Zonghai

2023.

Encyclopedia of Nanomaterials.

p.

649.

Wang, Xin

Cai, Jiyu

Velasquez Carballo, Kevin

Watanabe, Fumiya

and

Meng, Xiangbo

2023.

Tackling issues of lithium metal anodes with a novel polymeric lithicone coating.

Chemical Engineering Journal,

Vol. 475,

Issue. ,

p.

146156.

Karimzadeh, Sina

Safaei, Babak

Yuan, Chris

and

Jen, Tien-Chien

2023.

Emerging Atomic Layer Deposition for the Development of High-Performance Lithium-Ion Batteries.

Electrochemical Energy Reviews,

Vol. 6,

Issue. 1,

Yoshimura, Tetsuzo

2024.

Molecular layer deposition (MLD) for lightwave control and extended applications.

Nano-Structures & Nano-Objects,

Vol. 39,

Issue. ,

p.

101202.

Meng, Xiangbo

2024.

Interface engineering of lithium metal anodes via atomic and molecular layer deposition.

Inorganic Chemistry Frontiers,

Vol. 11,

Issue. 3,

p.

659.

Han, R.C.

Song, H.Y.

Li, S.

and

Guo, T.

2024.

Atomistic simulation of nanoindentation behavior of amorphous/crystalline dual-phase high entropy alloys.

Journal of Materials Science & Technology,

Vol. 197,

Issue. ,

p.

46.