Article contents

Anomalous size effects in nanoporous materials induced by high surface energies

Published online by Cambridge University Press: 05 April 2019

Abstract

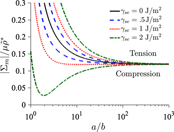

Several experiments and molecular dynamics calculations have reported anomalous mechanical behaviors of nanoporous materials that may be attributed to capillary effects. For example, nanoporous gold exhibits a tension–compression asymmetry in yield strength with the material being stronger in compression than tension. In addition, some molecular dynamics calculations have reported a spontaneous collapse of pores in nanoporous gold with nanometer-sized ligaments. Despite these perplexing observations, there are few theoretical models capable of shedding light on such capillary phenomena, particularly under general stress states. Here, we utilize a physics-based model to explore the implications of high surface energies on the mechanical response of dislocation-starved nanoporous materials subject to general stress states. For low stress triaxialities, we report an anomalous size effect and an anomalous temperature-dependence of dislocation-starved nanoporous materials with sufficiently large surface energies. Additionally, we provide an analytic criterion for spontaneous pore collapse in nanoporous materials with nanometer-sized ligaments.

Keywords

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 34 , Issue 13: Focus Issue: Intrinsic and Extrinsic Size Effects in Materials , 15 July 2019 , pp. 2337 - 2346

- Copyright

- Copyright © Materials Research Society 2019

References

- 11

- Cited by