Article contents

An in situ study on Kr ion–irradiated crystalline Cu/amorphous-CuNb nanolaminates

Published online by Cambridge University Press: 04 March 2019

Abstract

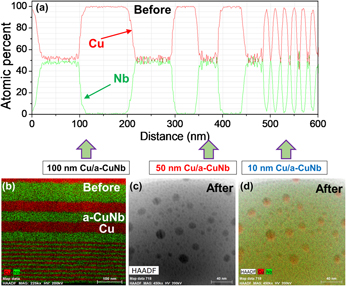

Nanocrystalline and nanolaminated materials show enhanced radiation tolerance compared with their coarse-grained counterparts, since grain boundaries and layer interfaces act as effective defect sinks. Although the effects of layer interface and layer thickness on radiation tolerance of crystalline nanolaminates have been systematically studied, radiation response of crystalline/amorphous nanolaminates is rarely investigated. In this study, we show that irradiation can lead to formation of nanocrystals and nanotwins in amorphous CuNb layers in Cu/amorphous-CuNb nanolaminates. Substantial element segregation is observed in amorphous CuNb layers after irradiation. In Cu layers, both stationary and migrating grain boundaries effectively interact with defects. Furthermore, there is a clear size effect on irradiation-induced crystallization and grain coarsening. In situ studies also show that crystalline/amorphous interfaces can effectively absorb defects without drastic microstructural change, and defect absorption by grain boundary and crystalline/amorphous interface is compared and discussed. Our results show that tailoring layer thickness can enhance radiation tolerance of crystalline/amorphous nanolaminates and can provide insights for constructing crystalline/amorphous nanolaminates under radiation environment.

- Type

- Invited Paper

- Information

- Journal of Materials Research , Volume 34 , Issue 13: Focus Issue: Intrinsic and Extrinsic Size Effects in Materials , 15 July 2019 , pp. 2218 - 2228

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

These authors contributed equally to this work.

References

- 14

- Cited by