Article contents

Adhesion strength and nanomechanical characterization of ZnO thin films

Published online by Cambridge University Press: 18 April 2017

Abstract

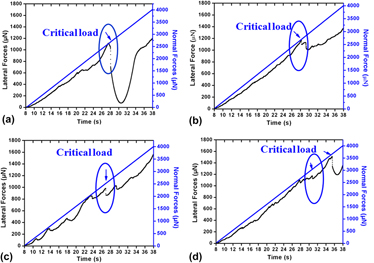

The present study was focused to investigate mechanical properties of ZnO thin films deposited on fused quartz substrates at different sputtering deposition pressures (5, 10, 15, and 20 mTorr) using DC sputtering. The crystallinity and microstructure show a marked influence on the mechanical properties of ZnO thin films. The structural evolution of the thin films is in (002) plane and influenced by deposition pressure. The intensity of (002) peak of the films rises initially and decreases with further increasing deposition pressure. The mechanical properties such as hardness, Young’s modulus, and coefficient of friction of ZnO thin films were measured using three-sided pyramidal Berkovich nanoindentation. The adhesion strength of thin films was measured by using scratch test under ramp loading. Load–displacement profile of thin films at continuous indentation cycle without any discontinuity revealed no fracture, cracking event, and defects, which is a consequence of dense microstructure and good adherence of films to the substrate.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Sam Zhang

References

REFERENCES

- 11

- Cited by